Internal sealing type grouting bottle

A grouting bottle and inner-sealing technology, which is applied to supply devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of occupying the space of the slurry tank, many impurities in the returning slurry, and difficult transfer, saving time and simplifying the production process. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

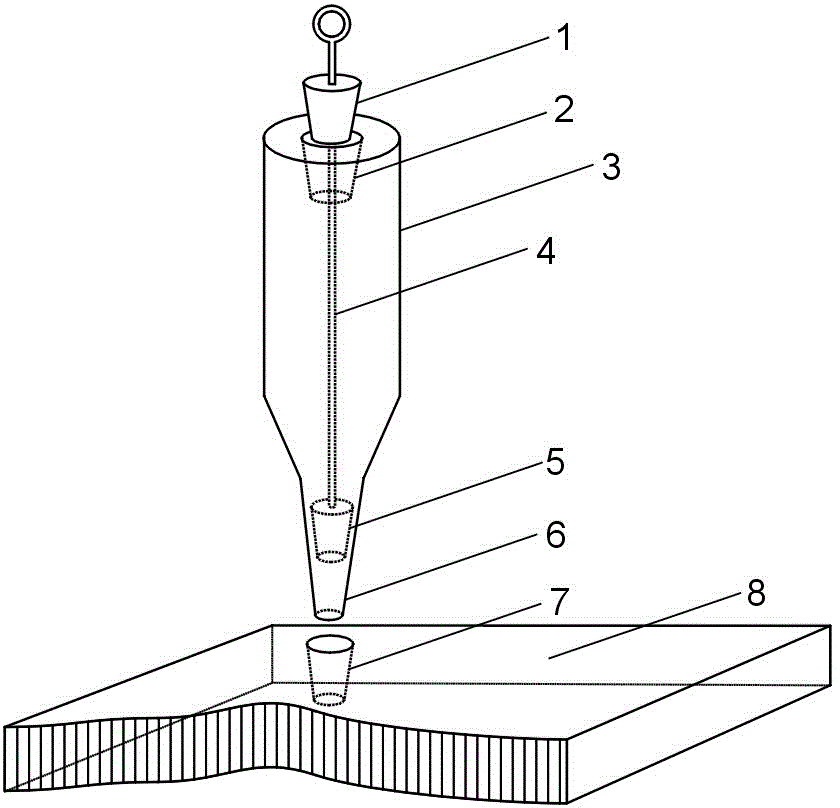

[0016] figure 1 A specific embodiment of the inner-sealed grouting bottle of the present invention is shown. The grouting interface 6 at the bottom of the bottle body 3 coincides with the in-mold tapered interface 7 formed in the plaster mold body 8 . The inner sealing rubber plug 5 at the lower end of the synchronous sealing rod 4 coincides with the inner wall of the grouting interface 6 . The sealing conical rubber stopper 1 on the upper end of the synchronous sealing rod 4 matches with the conical upper sealing 2 on the top of the bottle body 3 .

[0017] During the grouting after the second time, the upper sealing tapered rubber plug 1 and the inner sealing rubber plug 5 have sealed a small part of the remaining slurry in the bottle body 3 . Workers only need to insert the grouting interface 6 into the tapered interface 7 in the mold, and pull the synchronous sealing rod 4 away at will. At this time, a small amount of residual slurry in the bottle body 3 will flow into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com