Method for controlling concrete elevation by steel bar with hooked end

A technology of concrete and steel bars, applied in structural elements, building components, building reinforcements, etc., can solve the problem of non-slip surface of the upper steel bar, difficult to control the elevation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

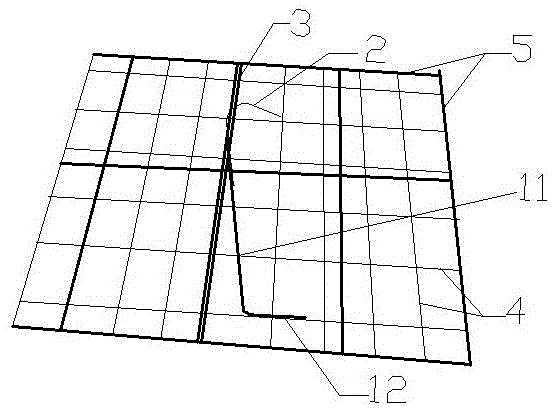

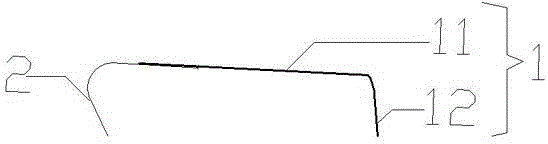

[0017] Such as Figures 1 to 2 As shown, it is an embodiment 1 of a method for controlling the level of concrete with a hook steel bar according to the present invention, including a steel bar bracket 1 and a steel bar hook 2, and the steel bar bracket 1 includes a steel bar bracket body 11 and a steel bar welded at the bottom end of the steel bar bracket 1 The diagonal brace 12, the steel bar support body 11 and the steel reinforcement diagonal brace 12 are steel bars of the same type, welded into an "L" shape.

[0018] In this implementation case, after the double-layer two-way steel bars of the bottom plate are bound, the diagonal bracing steel bars 12 of the "L" shaped steel bar bracket 1 are welded to the lower row of steel bars 4, the steel bar bracket body 11 is welded to the upper row of auxiliary steel bars 3, and the upper row The at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com