Crystal silicon/amorphous silicon thin-film stacked solar cell

A technology of amorphous silicon thin film and solar cells, which is applied in the field of solar cells, can solve problems such as limiting the development of heterojunction cells, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

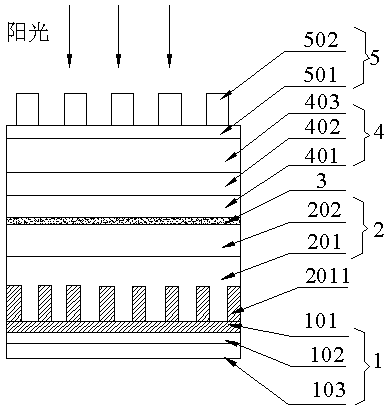

[0022] see figure 1 , the crystalline silicon / amorphous silicon thin-film laminated solar cell of the present invention is composed of a collector electrode layer 1, a bottom cell 2, a top cell 4, and a positive electrode layer 5 in sequence, and a layer is arranged between the bottom cell 2 and the top cell 4 Coupling film connection layer 3. The bottom cell 2 is a PN crystalline silicon cell prepared by forming a P-type diffusion layer 202 on an N-type crystalline silicon substrate 201 by a diffusion process. On the light-facing surface of the P-type diffusion layer 202 of the bottom cell 2, deposit a coupling thin-film connection layer 3 with a thickness of 0.1-100 nm, and the material is selected from one of ITO, ZnO, Ag, Cu, and Al. The top cell 4 is a PIN-type amorphous silicon thin film prepared by sequentially depositing an N-type amorphous silicon layer 401, an intrinsic amorphous silicon layer 402, and a P-type amorphous silicon layer 403 on the coupling layer 3 by ...

Embodiment 2

[0025] see still figure 1 , the crystalline silicon / amorphous silicon thin-film laminated solar cell of the present invention is composed of a collector electrode layer 1, a bottom cell 2, a top cell 4, and a positive electrode layer 5 in sequence, and a layer is arranged between the bottom cell 2 and the top cell 4 Coupling film connection layer 3. The bottom cell 2 is an NP crystalline silicon cell prepared by forming an N-type diffusion layer 202 on a P-type crystalline silicon substrate 201 by a diffusion process. On the N-type diffused layer 202 of the bottom cell 2 deposit a coupling thin-film connecting layer 3 with a thickness of 0.1-100 nm, and the material is selected from one of ITO, ZnO, Ag, Cu, and Al. The top cell 4 is a NIP-type amorphous silicon thin film prepared by sequentially depositing a P-type amorphous silicon layer 401, an intrinsic amorphous silicon layer 402, and an N-type amorphous silicon layer 403 on the coupling layer 3 by PECVD. Battery.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com