Wavelength conversion device, preparation method thereof and light-emitting device

A wavelength conversion device and excitation light technology, applied in the optical field, can solve the problems of high cost, low reflectivity, poor adhesion of metal reflective layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

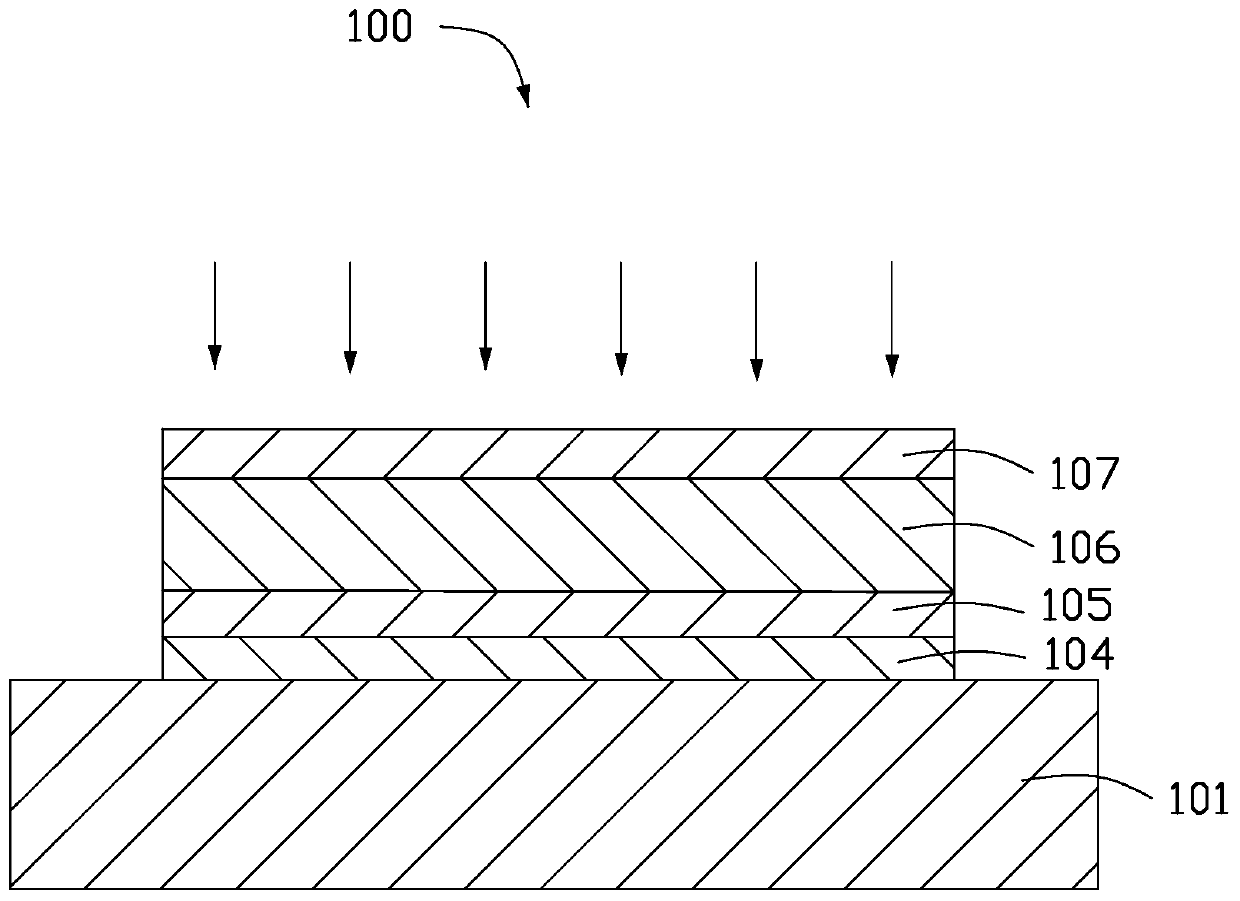

[0026] see figure 1 The wavelength conversion device 100 provided by an embodiment of the present invention at least includes a substrate 101, a metal reflective layer 104, a nano-silicon dioxide low-refractive index layer 105, a fluorescent ceramic layer 106, and a nano-silicon dioxide anti-reflection layer 107 that are sequentially stacked. . The nano-silica low-refractive index layer 105 and the nano-silica antireflection layer 107 are prepared by a sol-gel method.

[0027] In this embodiment, the excitation light generated by the light source irradiates the wavelength conversion device 100 from the side of the nano-silica anti-reflection layer 107 away from the substrate 101, and the fluorescent ceramic layer 106 converts the excitation light into a received light and emits it from the substrate 101. .

[0028] The nano-silica low-refractive index layer 105 and the nano-silica anti-reflection layer 107 are basically composed of nano-silica particles. The term "nano-sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com