A high reflectivity vertical structure light-emitting diode chip and its preparation method

A light-emitting diode and vertical structure technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of not meeting the expectations of cost performance, achieve good ohmic contact performance, reduce loss, and increase the effect of light reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

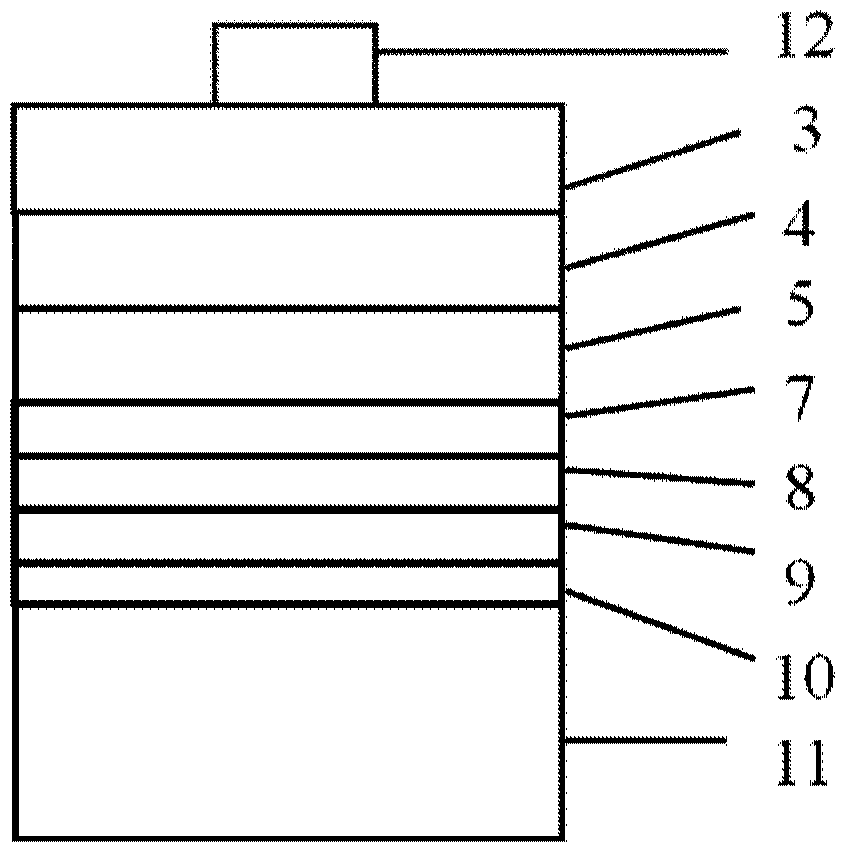

[0042] based on figure 1 The structure diagram of the vertical light-emitting diode chip with high reflectivity shown in the present invention also provides a preparation method of a vertical light-emitting diode chip with high reflectivity, comprising the following steps:

[0043]Step 1: select a substrate, and epitaxially grow a buffer layer, an N-type layer, a multi-quantum well layer and a P-type layer on the substrate in sequence to form an epitaxial layer;

[0044] Step 2: performing photolithographic etching on the epitaxial layer, and depositing a passivation layer;

[0045] Step 3: sequentially vapor-deposit an ohmic contact layer, a metal reflective layer, a barrier layer and an anti-oxidation layer on the passivation layer, and anneal to form a highly reflective P-type ohmic contact layer;

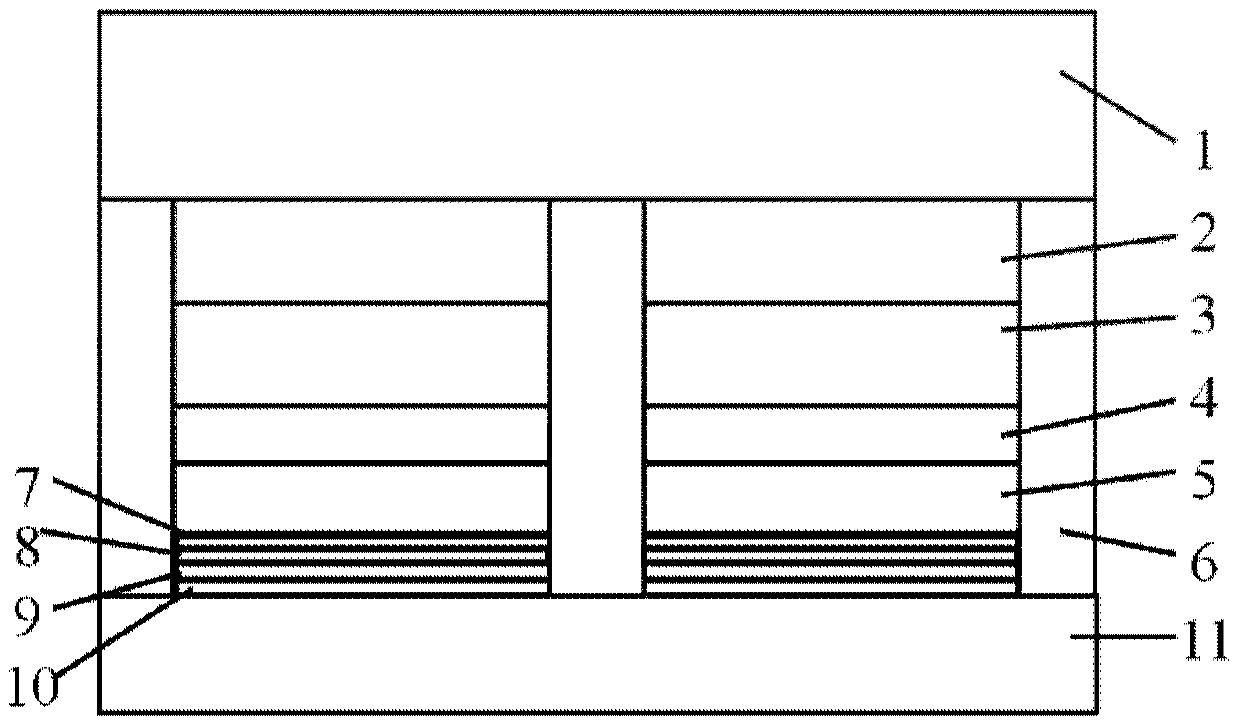

[0046] Step 4: Electroplating on the highly reflective P-type ohmic contact layer to make a heat dissipation substrate;

[0047] Step 5: removing the substrate and buffer laye...

Embodiment 1

[0053] The preparation method of the light-emitting diode chip with vertical structure in Example 1 of the present invention is as follows:

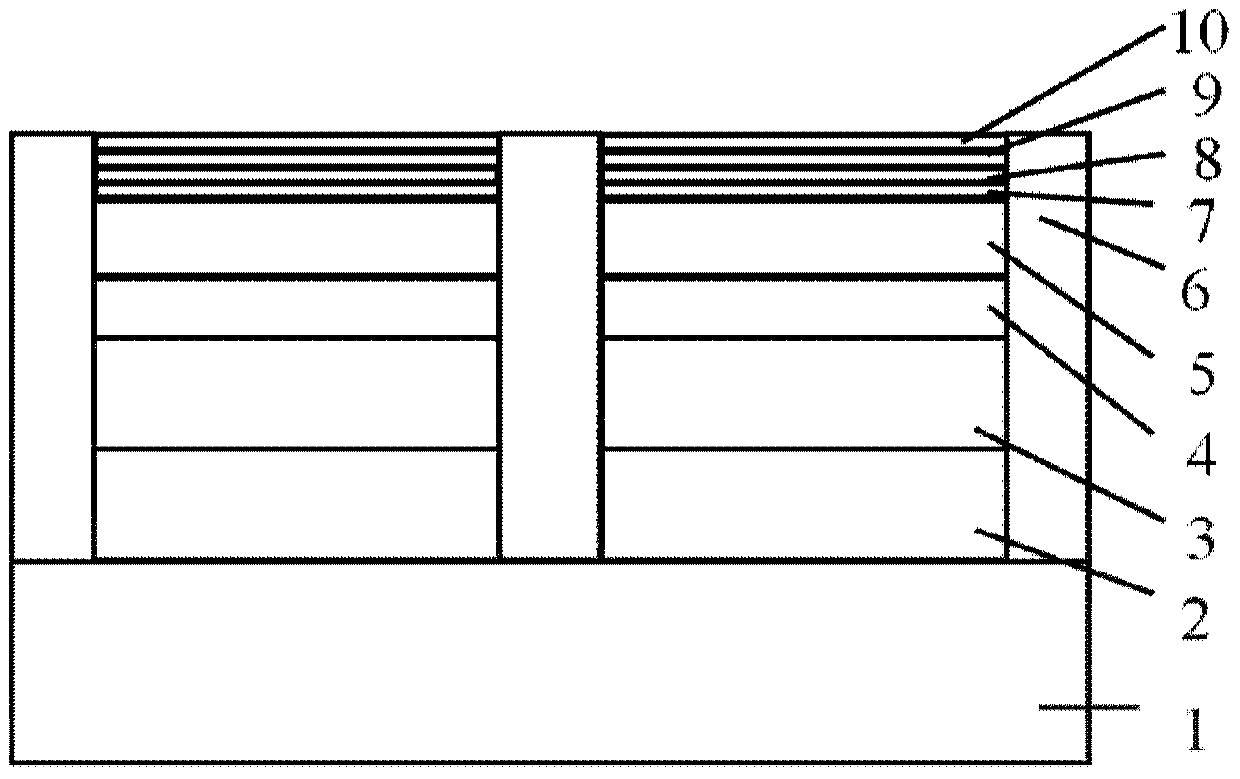

[0054] 1) Epitaxy on the sapphire substrate 1, grow buffer layer 2, N-type layer 3, multi-quantum well layer 4, P-type layer 5 in sequence, and then the wafer is heated at 700 ° C, N 2 Annealing under atmosphere for 20 minutes;

[0055] 2) Through photolithography and dry etching until the substrate, the etching depth is about 7 μm, and the platform is independent;

[0056] 3) Depositing a 2 μm passivation layer 6 to protect the etched sidewall, and the passivation layer 6 is made of silicon dioxide;

[0057] 4) Evaporating a highly reflective P-type ohmic contact layer, including: ohmic contact layer 7 (Ni), reflective layer 8 (Ag), barrier layer 9 (Ni) and anti-oxidation layer 10 (Au);

[0058] 5) 500°C in O 2 Annealing the highly reflective P-type ohmic contact layer under atmosphere;

[0059] 6) Electroplating metal Ni substrate ...

Embodiment 2

[0065] A buffer layer 2 , a GaN N-type layer 3 , a multi-quantum well layer 4 and a GaN P-type layer 5 are grown on a sapphire substrate 1 . Photolithography to form patterns, dry etching to the sapphire substrate, etching the side to deposit a passivation layer 6, and vapor-depositing a highly reflective P-type ohmic contact layer (ohmic contact layer 7, reflective layer 8, barrier layer 9 and anti-oxidation layer 10 ) and annealing, electroplating the metal substrate 11, removing the sapphire substrate 1, removing the buffer layer 2, evaporating the metal layer 12 to make an N electrode, and finally dicing, testing, and sorting the wafer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com