Antireflection film for quantum dot enhancement film (QDEF) and preparation method of antireflection film

A technology of quantum dot enhancement film and anti-reflection film, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of low brightness and contrast, and achieve the effects of reducing light loss, reducing optical loss, and reducing reflected light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

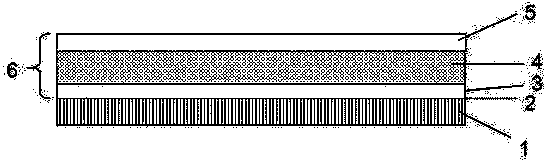

[0019] An embodiment of an anti-reflection film for a quantum dot enhanced film (QDEF) of the present invention is as follows figure 1 As shown, 3 and 5 are barrier layers, and 4 is a quantum dot layer. The quantum dot enhanced film 6 includes an anti-reflection film 1 . The antireflection film 1 is formed on the light incident surface 2 of the quantum dot enhanced film 6 .

[0020] In this embodiment, the anti-reflection coating 1 is a single layer, magnesium fluoride is selected as the material of the anti-reflection coating 1 , and its refractive index is 1.38. Through calculation, the thickness of the anti-reflection coating 1 is determined to be 86.05 nm. Put the quantum dot-enhanced film 6 into the cavity, and evacuate it. When the vacuum degree reaches 3*10 -3 At this time, the magnesium fluoride thin film is evaporated on the light incident surface 2 of the quantum dot enhanced film 1 by means of electron beam evaporation. Through test and comparison, compared with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com