Fluorescent powder glue coating method and application thereof

A phosphor and glue coating technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of phosphor deposition process and complexity, and achieve the effects of improving luminous efficiency, suppressing white light, and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

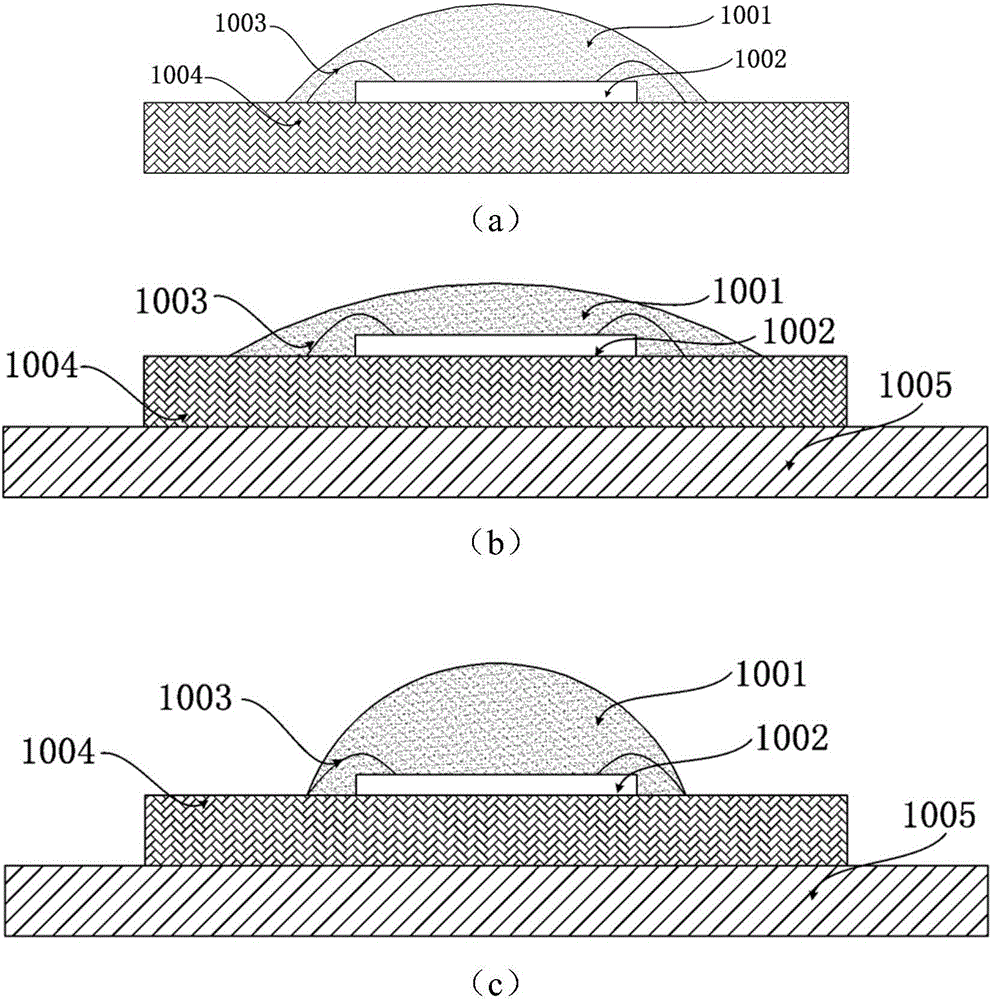

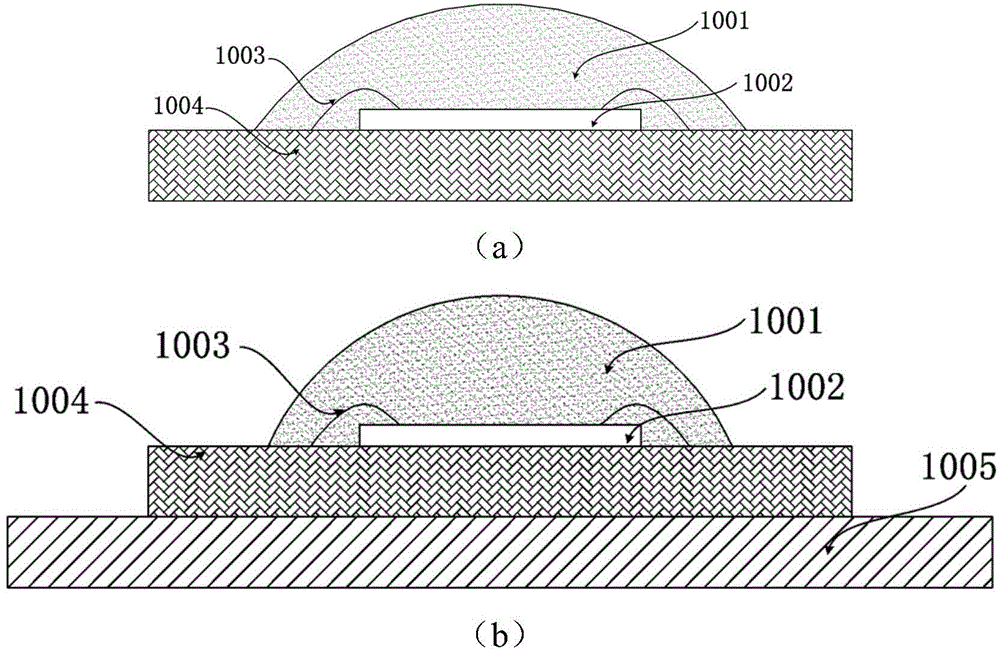

[0044] This embodiment is used for array packaging, and its substrate is made of planar aluminum material. Firstly, the substrate is heated to 100°C, and 2ul of fluorescent powder glue with a concentration of 2g / ml is injected on the planar substrate with a syringe. Powder glue is epoxy resin glue containing TAG fluorescent powder. After injecting the phosphor glue, after injecting the phosphor glue, the phosphor glue is stably molded and solidified within 4 minutes, and then it changes from a gel state to a solid state within 40 minutes to complete the curing.

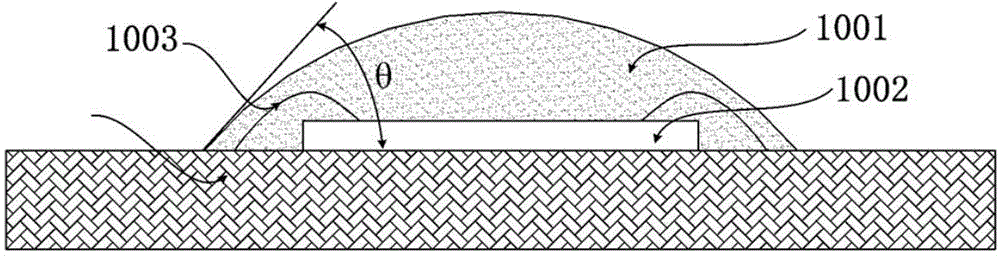

[0045] The test found that the shape of the fluorescent powder glue is spherical cap shape, and the curvature of the spherical cap-shaped phosphor powder glue is 35°.

Embodiment 2

[0047] This embodiment is used for system packaging, and its substrate is made of planar copper material. First, the substrate is heated to 120°C, and 2 ul of fluorescent powder glue with a concentration of 0.3g / ml is injected on the planar substrate with a syringe. Powder glue is TAG fluorescent powder contained in liquid glass. After injecting the phosphor glue, the phosphor glue was stably molded and cured within 3 minutes, and then completely changed from a gel state to a solid state within 20 minutes to complete the curing.

[0048] The test found that the shape of the fluorescent powder glue is spherical cap shape, and the curvature of the spherical cap-shaped phosphor powder glue is 50°.

Embodiment 3

[0050] This embodiment is used for printed circuit board packaging, and its substrate is a planar silicon material. First, the substrate is heated to 150° C., and 1 ul of phosphor glue with a concentration of 0.3 g / ml is injected on the planar substrate with a syringe. The fluorescent powder glue contains TAG fluorescent powder in silica gel. After injecting the phosphor glue, the phosphor glue was stably molded and solidified within 2 minutes, and then completely changed from a gel state to a solid state within 10 minutes to complete the curing.

[0051] The test found that the shape of the fluorescent powder glue is spherical cap shape, and the curvature of the spherical cap-shaped phosphor powder glue is 70°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com