Reflection sheet and backlight module

A technology of backlight module and reflective sheet, which is applied in the field of reflective sheet, can solve the problems such as difficult control of PET film thickness, narrowing of PET film gap, and reduction of light reflection efficiency of reflective sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

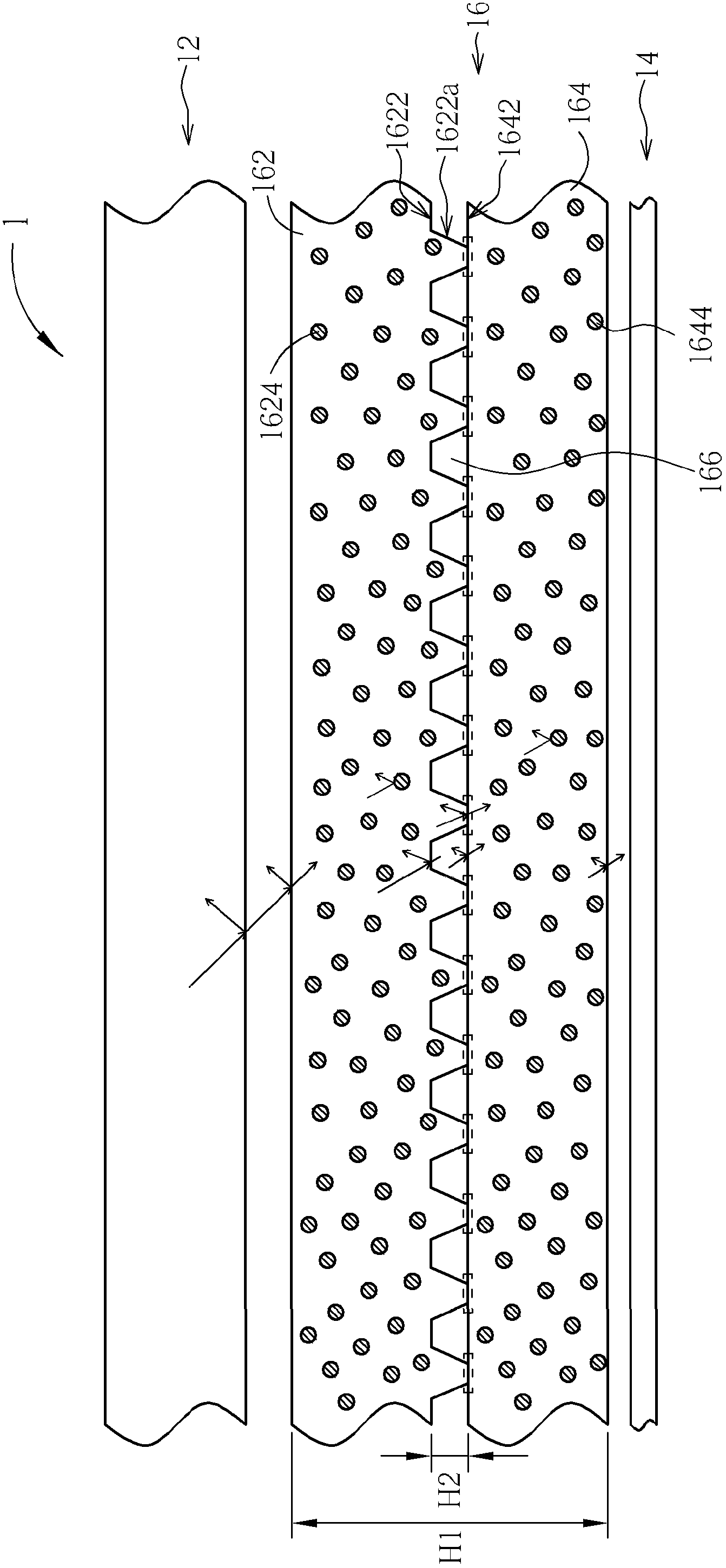

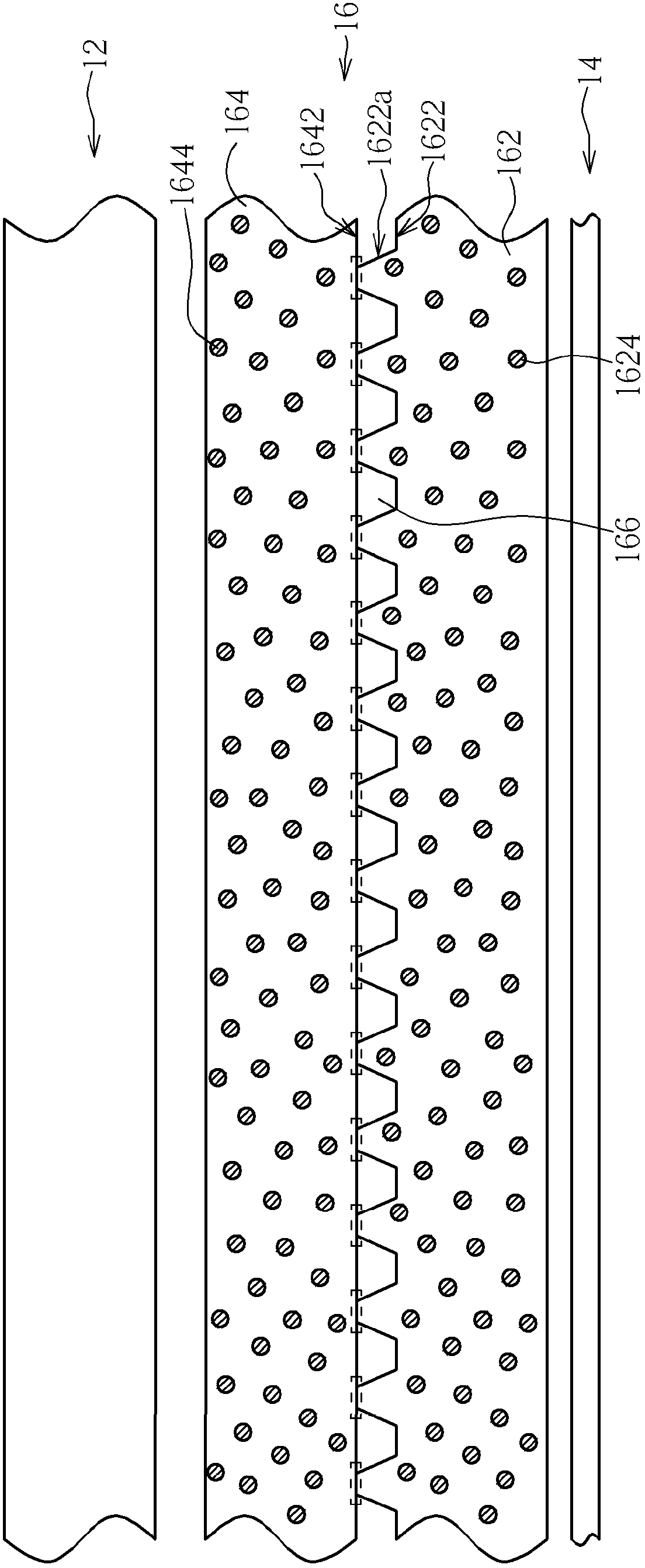

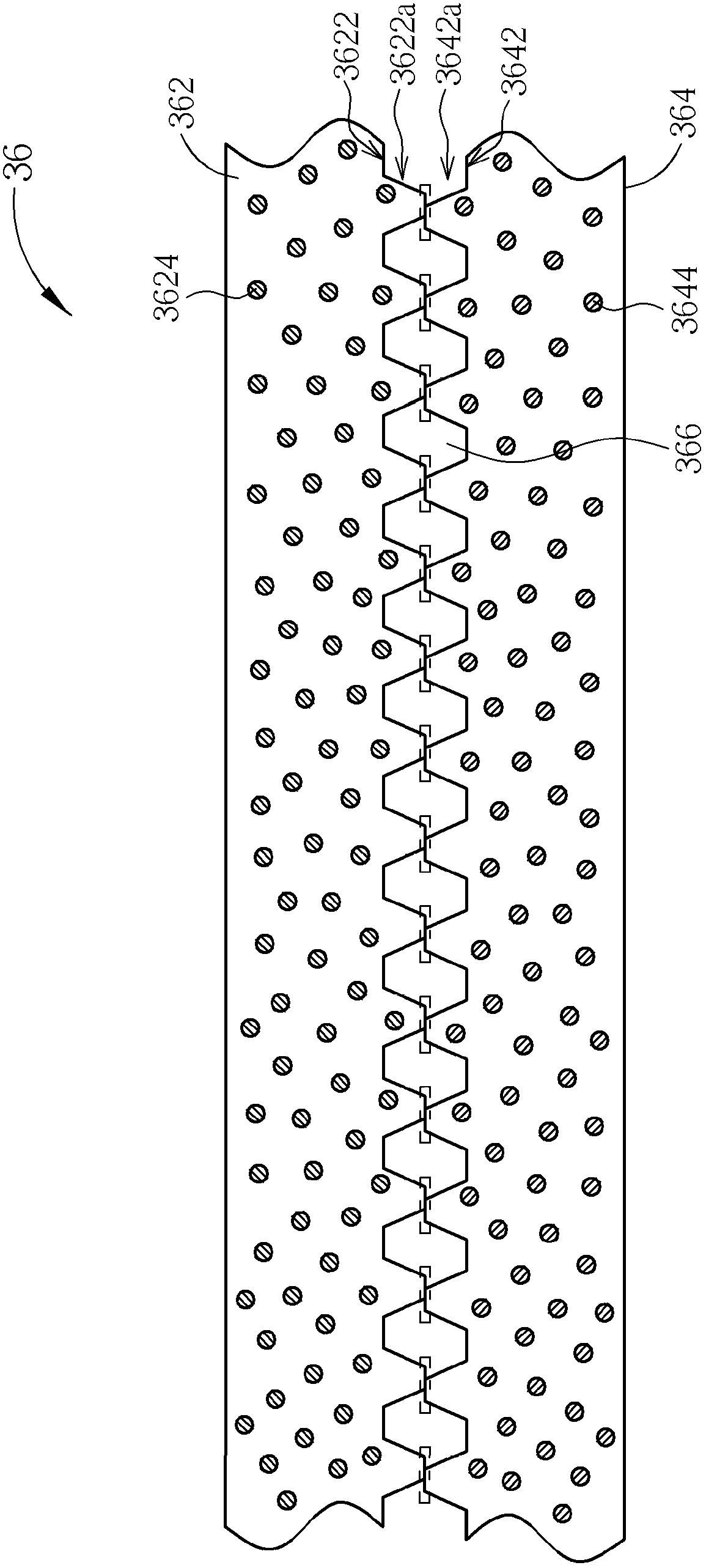

[0025] see figure 1 , which is a cross-sectional view of the backlight module 1 according to a preferred embodiment of the present invention. The backlight module 1 includes a light source module 12 , a backplane 14 and a reflective sheet 16 disposed between the light source module 12 and the backplane 14 . In this embodiment, the backlight module 1 is used to provide a surface backlight, such as the backlight required by a liquid crystal display. In practice, the light source module 12 usually includes a light source and a light guide plate, and the light guide plate is used to transmit and diffuse light emitted from the light source. light, the light source module 12 in figure 1 The part shown in is the light guide plate, but the present invention is not limited thereto. For example, in practical applications, the light source module of the present invention can also be a general light source directly. The back plate 14 can be a structural part of the backlight module 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com