Multilayer arrayed LED light engine

A light-emitting diode, multi-layer technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems that affect the structural strength, cannot require air tightness, and cannot be used for a long time, so as to improve the light reflection efficiency and luminescence Efficiency and brightness, and the effect of preventing moisture failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after reading this specification.

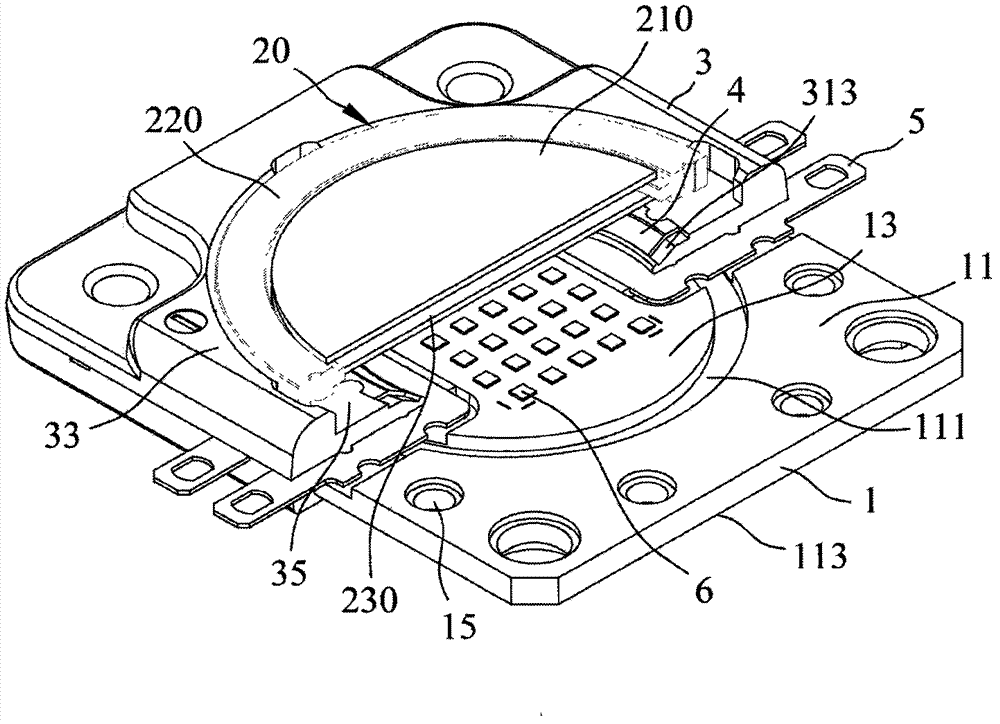

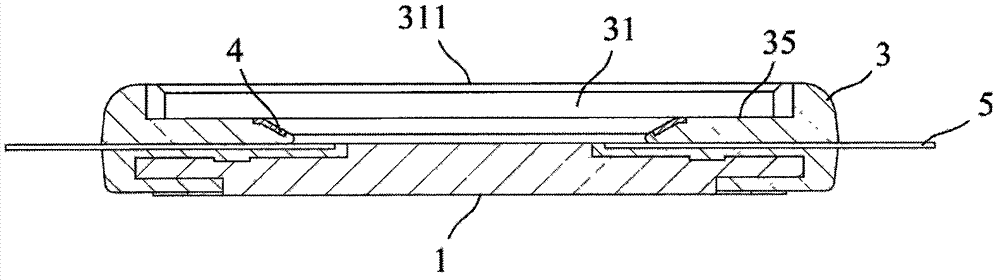

[0017] refer to figure 1 , a three-dimensional cross-sectional view of a multi-layer array type LED light engine capable of preventing moisture of the present invention. The invention relates to a multilayer array type light emitting diode light engine, which can completely prevent moisture from entering the interior of the multilayer array type light emitting diode light engine, and prevent the internal important components from being damp and deteriorating. The multilayer array LED light engine at least includes a substrate 1 , a packaging body 3 , two lead frame pairs 5 , a plurality of LED chips 5 and an optical lens group 20 .

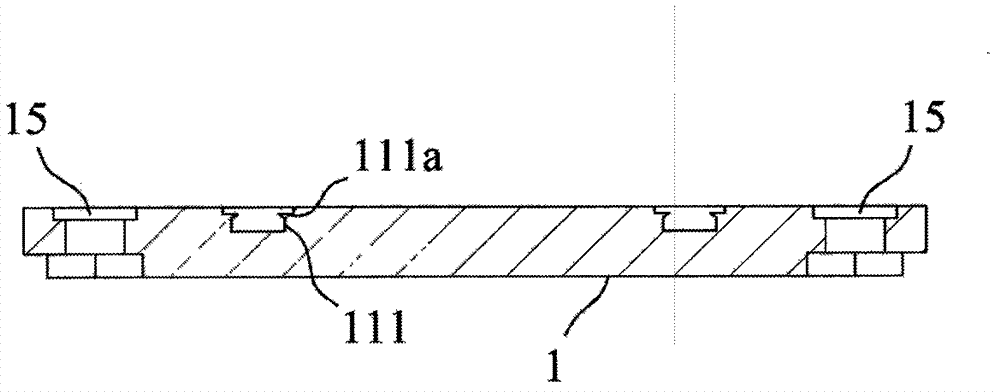

[0018] The substrate 1 has a surface 11, a light exit portion 13 and a plurality of packaging holes 15, the light exit portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com