Method and system for disposing incineration fly ash of household garbage

A technology for incineration and treatment of domestic waste, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problem of not ensuring the re-entry of heavy metals into the environment, and achieve significant economic benefits and environmental protection effects, treatment methods Simple, cost- and land-use reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1:

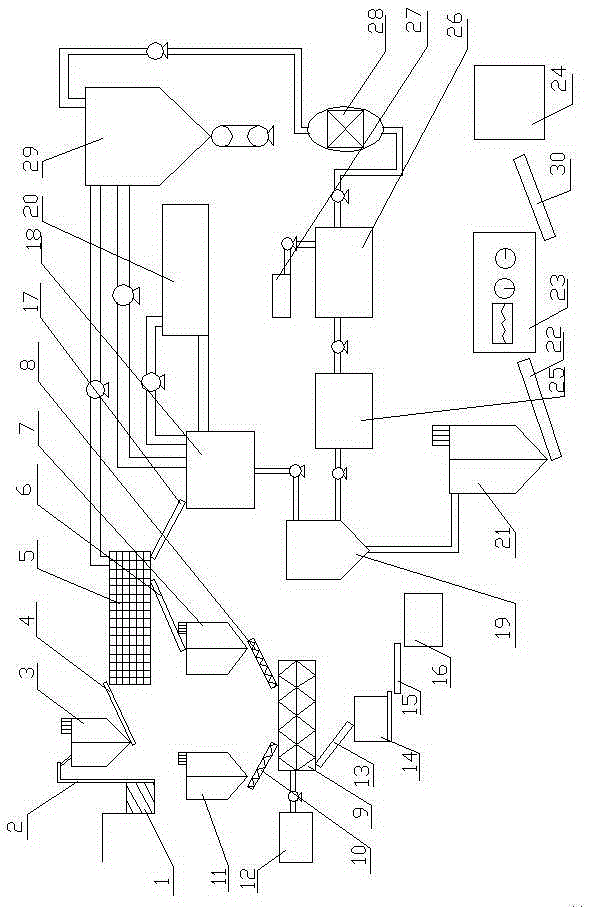

[0035] like figure 1 As shown, the present invention includes a first fly ash storage pit 1, the first fly ash storage pit 1 is connected with a first fly ash storage bin 3 through a hoist 2, and the first fly ash storage bin 3 is connected to an electric motor through a fly ash conveyor 4. The vibrating screen 5 is connected, and the small particle size fly ash output port of the electric vibrating screen 5 is connected to the second fly ash storage bin 7 through the small particle size fly ash conveyor 6, and the second fly ash storage bin 7 passes through the fly ash screw feeder. 8 is connected with the fly ash input port of the mixer 9, the mixer 9 also includes a cement input port and a chelating agent input port, and the cement input port of the mixer 9 passes through the cement screw feeder 10 and the output of the cement storage bin 11. The chelating agent input port of the mixer 9 is connected with the output end of the chelating agent solution t...

Example Embodiment

[0056] Embodiment 2:

[0057] The processing architecture and processing steps of this embodiment are the same as those of the first embodiment, and there are only differences in parameters:

[0058] In step 2), the moisture content of the original fly ash is 10%, and the aperture size of the vibrating screen is 45 μm.

[0059] Step 3) The mass ratio of small and medium-sized fly ash to cement is 10:1.

[0060] In step 5), the curing time on the horizontal endless conveyor is 1h.

[0061] Step 8) The mass ratio of medium and large particles of fly ash to the aqueous solution is 1:10, and the number of repeated washings is 5 times.

[0062] After the treatment in this example, the removal rate of chlorine element and heavy metals in the large particle fly ash separated from the household waste incineration fly ash can reach 85.09%, and the leaching property of the waste incineration fly ash reaches the standard.

Example Embodiment

[0063] Embodiment three:

[0064] The processing architecture and processing steps of this embodiment are the same as those of the first embodiment, and there are only differences in parameters:

[0065] In step 2), the moisture content of the original fly ash is 25%, and the aperture size of the vibrating screen is 70 μm.

[0066] Step 3) The mass ratio of small and medium-sized fly ash to cement is 15:1.

[0067] In step 5), the curing time on the horizontal endless conveyor is 2h.

[0068] Step 8) The mass ratio of medium and large particles of fly ash to the aqueous solution is 1:15, and the number of repeated washings is 5 times.

[0069] After the treatment in this embodiment, the removal rate of chlorine element and heavy metals in the large particle fly ash separated from the household waste incineration fly ash can reach 90.75%, and the leaching property of the waste incineration fly ash reaches the standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com