Dual-purpose saw blade with deep saw teeth and shallow saw teeth

A deep and shallow tooth saw technology, applied in the field of dual-purpose deep and shallow tooth saw blades, can solve the problems of insufficient sharpness for production use, low cutting efficiency of saw blades, and unsmooth chip removal, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

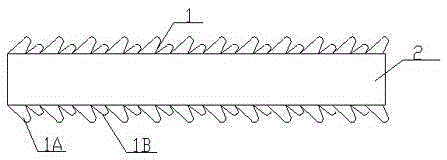

[0014] like figure 1 Shown is a schematic structural diagram of the present invention, a dual-purpose saw blade with deep and shallow teeth, including a sawtooth body 2, and sawtooth 1 is continuously arranged on both sides of the sawtooth body 2 along the axis direction, and the sawtooth 1 is divided into deep-toothed sawtooth 1A and shallow-toothed sawtooth There are two types of 1B, deep teeth and shallow saws 1A, the teeth are continuously arranged at intervals and distributed on both sides of the sawtooth body 2, and both sides of the sawtooth body 2 of the present invention are provided with sawtooth 1, which improves the utilization rate of materials as much as possible and avoids excessive waste.

[0015] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com