Multi-freedom-degree industrial machine operation arm mechanism

A technology for industrial machines and operating arms, applied in claw arms, manipulators, manufacturing tools, etc., can solve the problems of high cost of hydraulic components, high maintenance costs, insensitive response, etc. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

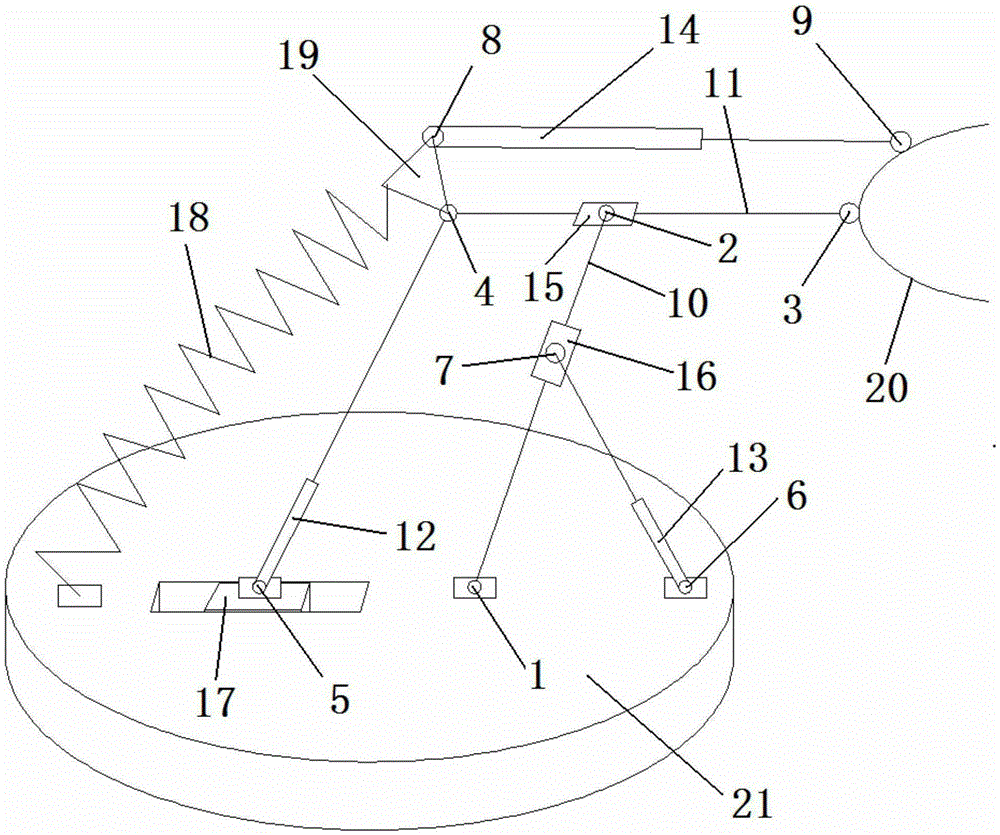

[0016] Multi-degree-of-freedom industrial machine operating arm mechanism, including rod one 10, rod two 11, telescopic rod one 12, telescopic rod two 13, telescopic rod three 14, sliding sleeve one 15, sliding sleeve two 16, slider 17, spring 18, Triangular connecting plate 19, actuator 20, working platform 21 and trolley,

[0017] The lower end of the rod one 10 is connected to the working platform 21 through the rotating pair one 1, and the upper end of the rod one 10 is connected to the sliding sleeve one 15 through the rotating pair two 2, and the sliding sleeve one 15 is sleeved on the rod two 11, and one end of the rod two 11 Connected on the actuator 20 by rotating pair three 3, the other end of rod two 11 is connected with the upper end of telescopic rod one 12 by rotating pair four 4, and the lower end of telescopic rod one 12 is connected on the slide block 17 by rotating pair five 5, and slide block 17 Installed in the chute on the working platform 21,

[0018] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com