Textile bobbin with abrasion resisting effect

A bobbin and casing technology, applied in the field of textile bobbins, can solve the problems of reduced spraying efficiency and unreliable yarn processing, etc., and achieve the effects of reducing the coating area, convenient coating, and saving use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

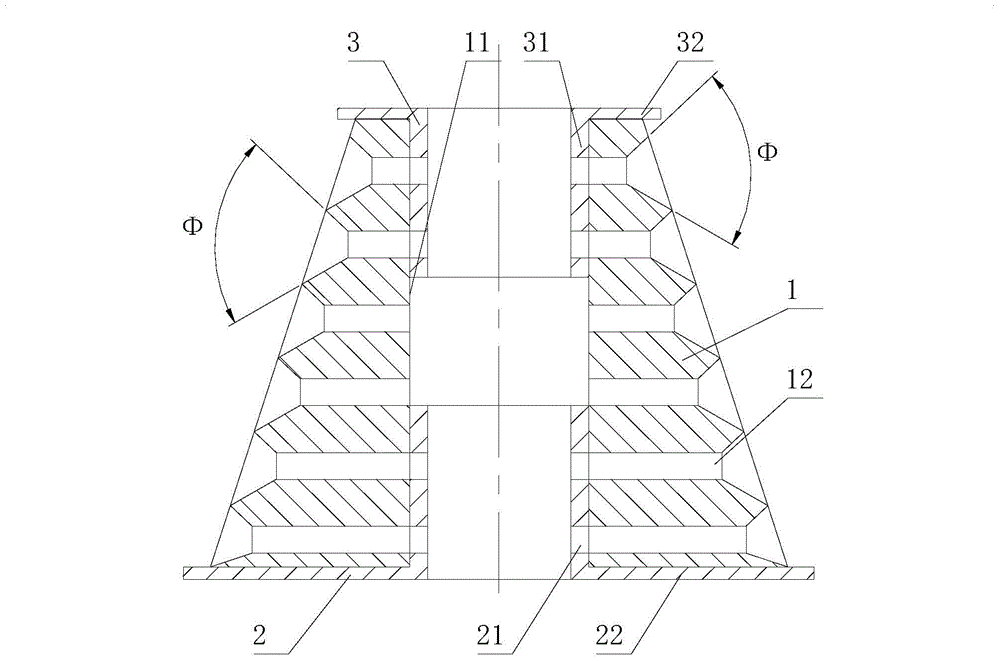

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0018] like figure 1 As shown, a textile bobbin with wear-resistant effect includes a tapered tube body 1, the middle part of the tapered tube body 1 is provided with a tube body installation hole 11 along the axial direction, and the lower section of the tube body installation hole 11 is sleeved with a The disassembled first connector 2, the upper section of the pipe body installation hole 11 is sleeved with a detachable second connector 3, the first connector 2 includes a first sleeve 21 that matches the pipe body installation hole 11, and the second connection The part 3 includes a second sleeve 31 matched with the pipe mounting hole 11, the first sleeve 21 is away from the second sleeve 31, the inner hole 1 of the first sleeve 21 and the inner hole 2 of the second sleeve 31 are in common with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com