Diversion centralizer and petroleum instrument

A technology of centralizer and diversion body, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., which can solve the problems of irregular mud shaking, short life, poor centralizing effect, etc., to solve irregular shaking, prolong service life, The effect of reducing the chance of being corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

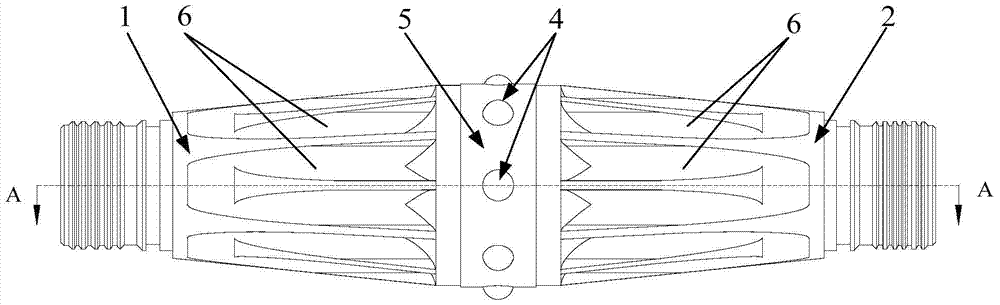

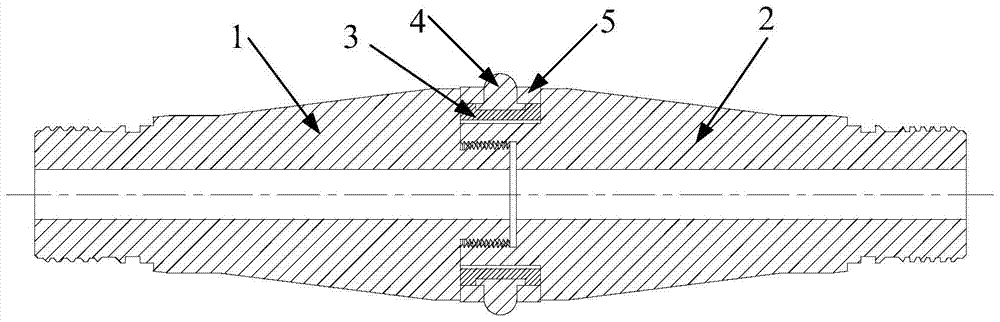

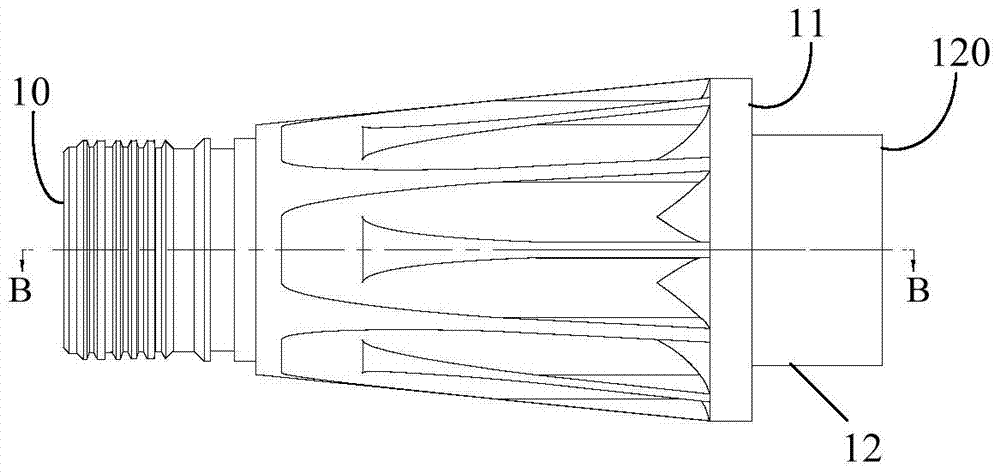

[0035] The embodiment of the present invention provides a diversion-type centralizer, which solves the problem that the rubber block on the centralizer is severely corroded, and the problem of short service life caused by the friction between the rubber block and the inner wall of the drill pipe cavity is relatively large. At the same time, it can Alleviate the impact of high friction between the rubber block and the inner wall of the drill pipe cavity on the salvage or hoisting of petroleum instruments.

[0036] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the embodiments of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention are described below in conjunction with the accompanying drawings The program is described in further detail.

[0037] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com