Convex-concave engaging type telescopic positioning device

A telescopic positioning, concave-convex technology, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of low reliability, laborious, easy sinking and rotation of the saddle, and achieve reliable performance, convenient operation, and low weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

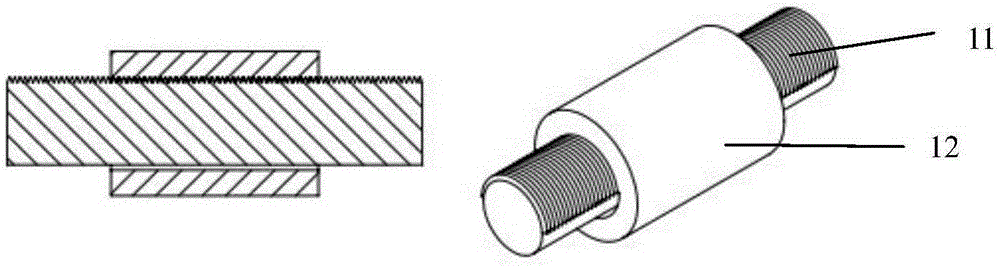

[0033] as attached figure 1 As shown, the rotary engagement mechanism is a rotary engagement mechanism of an incomplete circular thread, and the rotary engagement mechanism of the incomplete circular thread includes an incomplete circular external thread and an incomplete circular internal thread meshing with it, and the incomplete circular thread The circular external thread and the incomplete circular internal thread are evenly and continuously distributed in the axial direction, the incomplete circular external thread is distributed on the circular arc surface in one segment, and the one-stage incomplete circular The internal thread 12 and the one-piece non-complete circular external thread 11 engaging with it have corresponding thread engagement features.

[0034] The one-stage incomplete circular external thread 11 and the one-stage incomplete circular internal thread 12 meshed with it have a thread arc of 175°, and the depth of the non-thread separating groove on the inc...

Embodiment 2

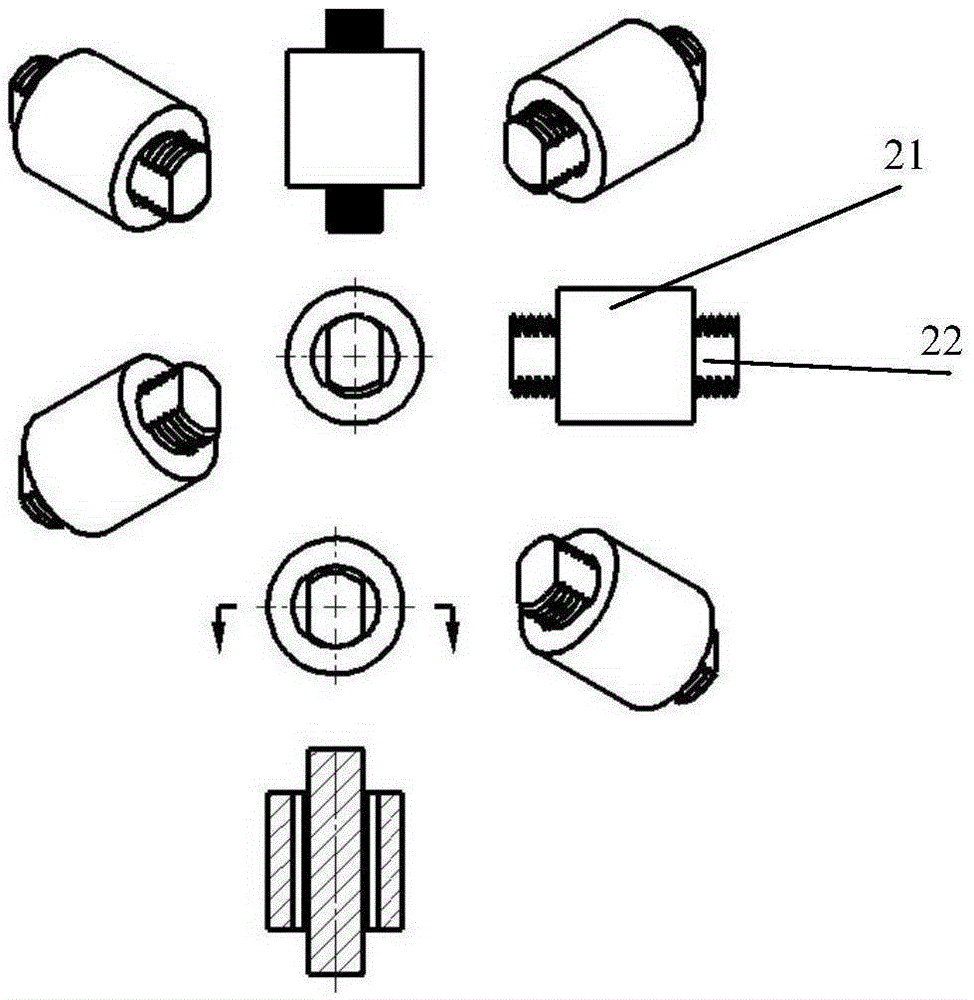

[0036] as attached figure 2 As shown, the rotary engagement mechanism is a rotary engagement mechanism of an incomplete circular thread, and the rotary engagement mechanism of the incomplete circular thread includes an incomplete circular external thread and an incomplete circular internal thread meshing with it, and the incomplete circular thread The circular external thread and the incomplete circular internal thread are evenly and continuously distributed in the axial direction. The incomplete circular external thread is divided into two sections and evenly distributed on the circular arc surface. The two-stage incomplete circular The arc of each section of thread on the external thread 22 is not greater than the arc of each section of non-threaded separation groove, the arc of each section of thread on the two-stage non-complete circular external thread 22 is 88°, and the non-threaded separation The depth of the groove is greater than the tooth height of the thread, and t...

Embodiment 3

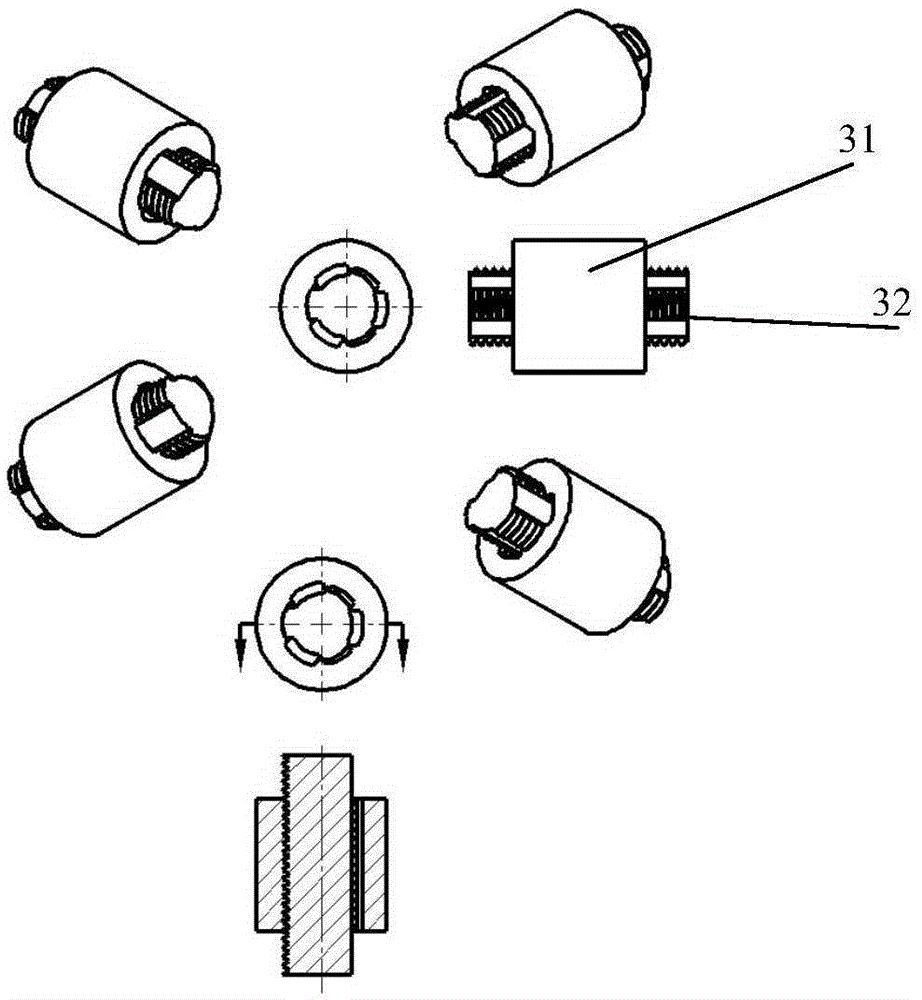

[0038] as attached image 3As shown, the rotary engagement mechanism is a rotary engagement mechanism of an incomplete circular thread, and the rotary engagement mechanism of an incomplete circular thread includes an incomplete circular external thread and an incomplete circular internal thread meshing with it, and the incomplete circular external thread The non-complete circular internal thread is evenly and continuously distributed in the axial direction, and the non-complete circular external thread is divided into three sections and evenly distributed on the circular arc surface. The three-stage non-complete circular external thread 32 The radian of each segment of the thread is not greater than the radian of each segment of the non-threaded separation groove, the arc of each segment of the thread on the three-segment incomplete circular external thread 32 is 58°, and the depth of the non-threaded separation groove is greater than that of the thread The three-stage incompl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com