Online rapid measurement apparatus and method for detecting rivet point dimension

A technology of size detection and measuring device, applied in measuring devices, instruments, etc., can solve the problems of lack, time-consuming and laborious manual measurement, poor accuracy, etc., and achieve the effect of being qualified, accurate and reliable, ensuring consistency, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

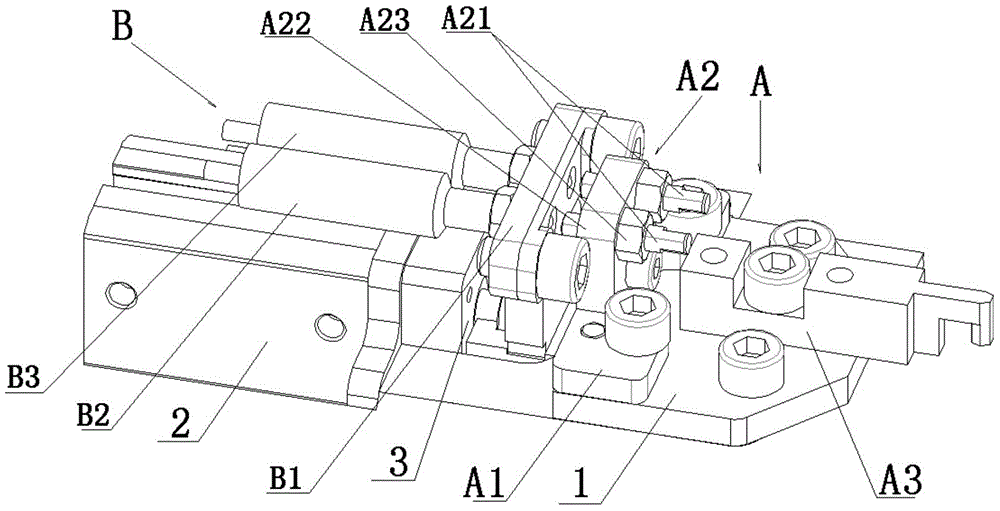

[0028] Such as figure 1 with figure 2 As shown, the on-line rapid measuring device for riveting point size detection includes a measuring base plate 1, and a stretching cylinder 2 is arranged on one end of the measuring base plate, and the cylinder is connected with a riveting point size detection assembly on the measuring base plate through a coupling 3 A connection;

[0029] A sensor assembly B is arranged on the surface of the measurement base plate 1 on one side of the riveting point size detection component A, and the sensor component is facing the riveting point size detection component;

[0030] The riveting point size detection component A is controlled by the stretching cylinder 2 to move left and right, and cooperates with the sensor component B to detect the riveting point size.

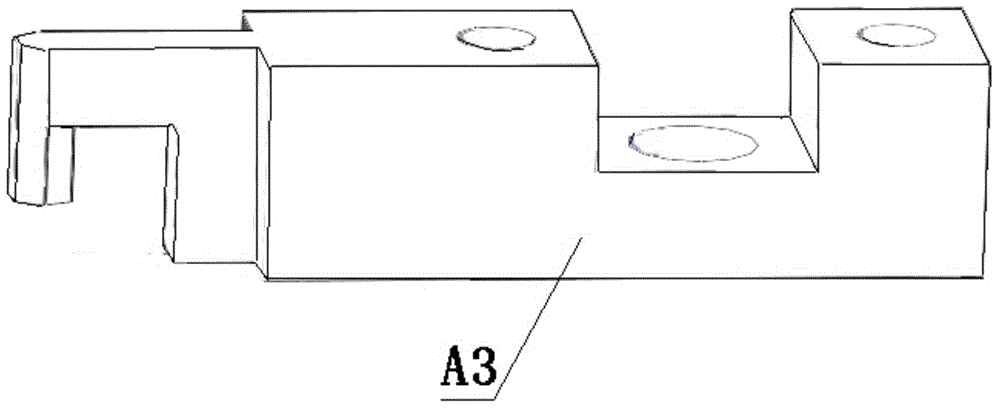

[0031] The riveting point size detection assembly A includes a sensor base A1, a sensor contact shaft assembly A2 and a riveting point detection probe A3, wherein the sensor base is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com