Parallel lightning arrester group breakdown monitoring method based on grating temperature measurement

A lightning arrester, parallel technology, applied in the direction of instruments, thermometers, measuring electricity, etc., can solve problems such as unsatisfactory data collection, and achieve the effect of solving electromagnetic interference, solving dynamic characteristics, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

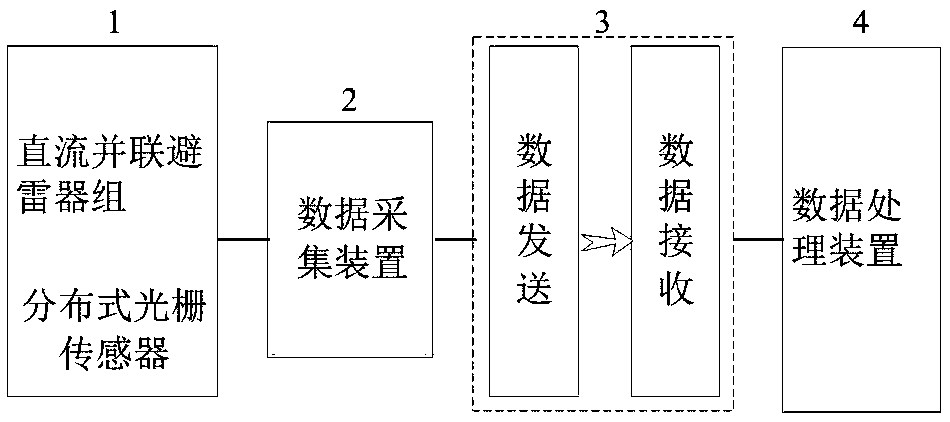

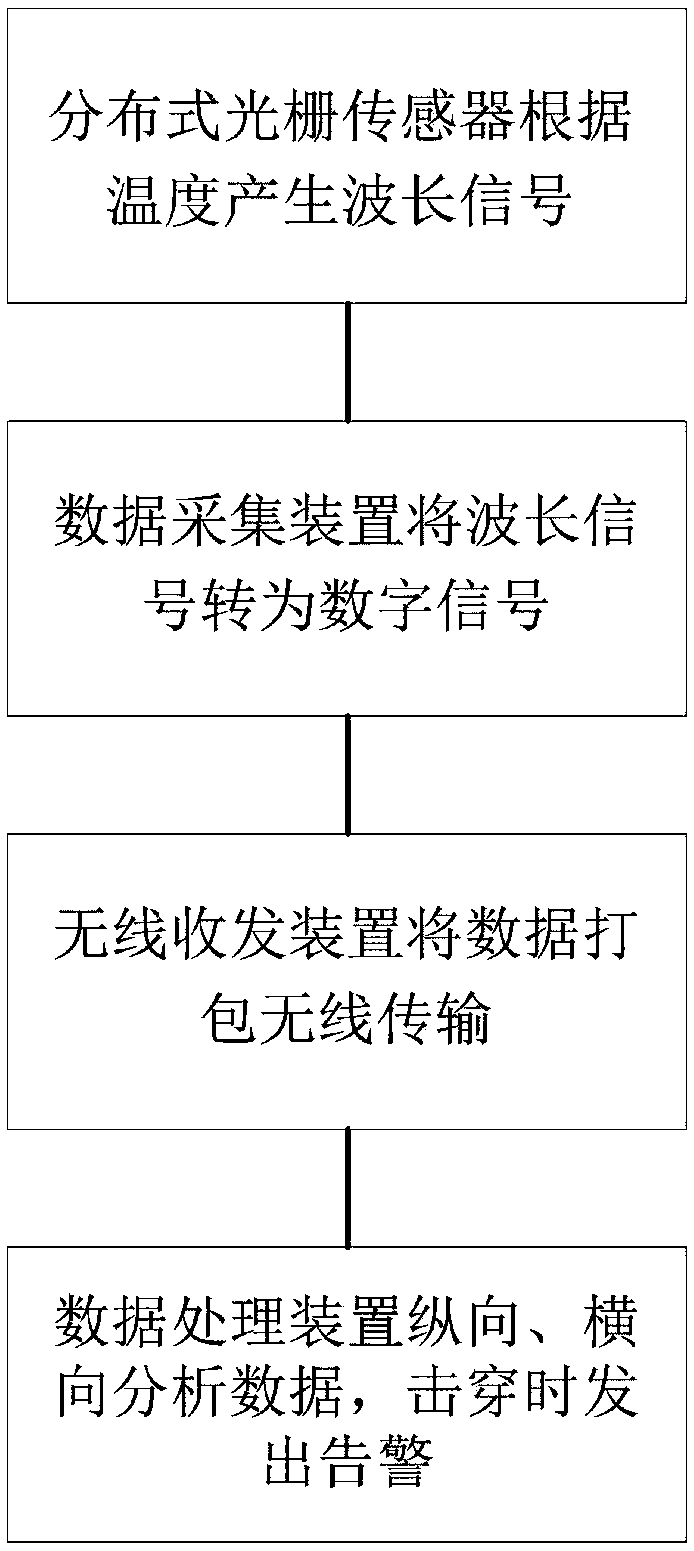

[0010] Such as figure 2 As shown, the present invention provides a method for monitoring the breakdown of parallel arrester groups based on grating temperature measurement, which includes the following steps: first, a fiber optic grating temperature sensor is evenly installed on the outer wall of the insulating porcelain bottle of the arrester group, and the temperature data of the arrester group is collected. The obtained optical signal is demodulated and converted into a digital signal through the data acquisition device. The wireless transceiver device packs the digital signal and transmits it to the data processing device through wireless mode. When the data processing device finds that the temperature of the arrester group exceeds the threshold, it will alarm.

[0011] Wherein the data processing device collects the temperature data of the arrester group in real time, compares the temperature data with the historical temperature data of the arrester group, and compares th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com