Structure device applied to self-flowing type fluid ultrasonic measurement

An ultrasonic measurement and self-flowing technology, which is applied in the structural field of fluid physical quantity measurement, can solve problems such as impracticability and high automation control, and achieve the effect of improving measurement accuracy and reducing bubble content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

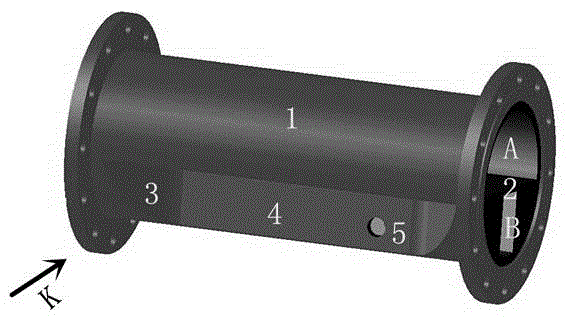

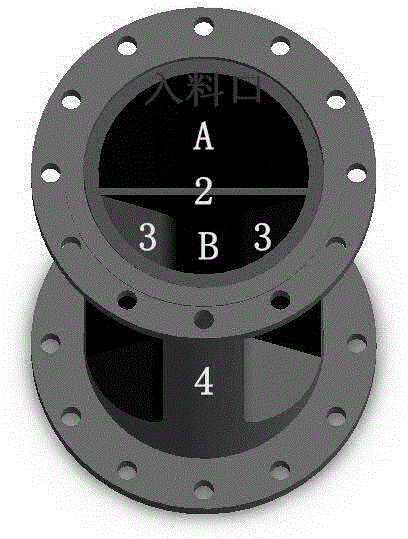

[0012] The structure of the patent of the present invention will be described in detail in conjunction with the accompanying drawings.

[0013] A structure for measuring fluid physical quantities in self-flowing pipelines. A baffle (2) for reducing fluid tumbling is installed in the pipeline main body (1), and a pair of fluid buffers are installed at the inlet of the pipeline main body (1). Plate (3), connected to the clamping groove (4) with fixed distance behind the fluid buffer plate (3), behind the clamp groove (4) with fixed distance, provide a pair of fixing holes (5) for installing the sensor .

[0014] According to the design filling rate of the self-flowing pipeline is 40% to 60% of the cross-sectional area of the pipe section, the baffle (2) needs to be installed at the horizontal diameter of the main body (1) of the pipeline, so that the cross-sectional area of space A is equal to the cross-sectional area of the pipeline half of , the angle between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com