Bottleneck defect detection method adopting residual analysis and dynamic threshold segmentation

A dynamic threshold and defect detection technology, applied in the field of image processing, can solve the problem of low detection accuracy of bottle mouth defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

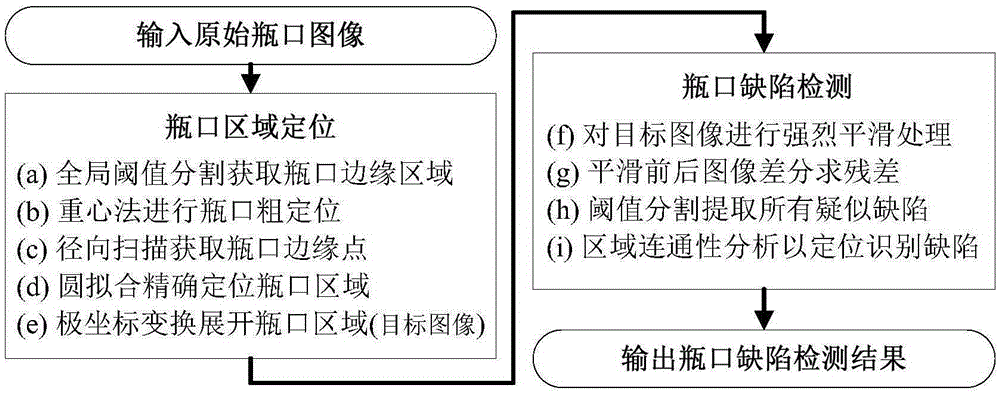

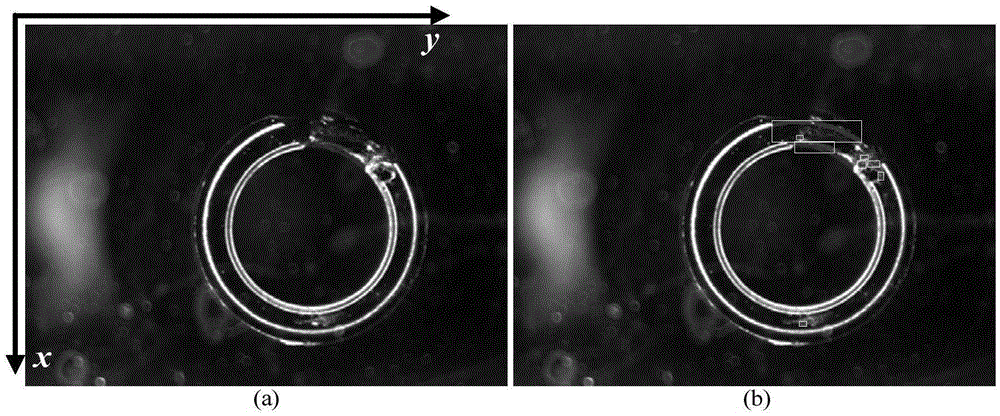

[0079] A bottleneck detection method based on residual analysis and dynamic threshold segmentation, the detailed steps are as follows figure 1 As shown in Fig. 1, it mainly includes two processing flows: positioning of the bottle mouth area and detection of bottle mouth defects.

[0080] 1 bottle mouth area positioning

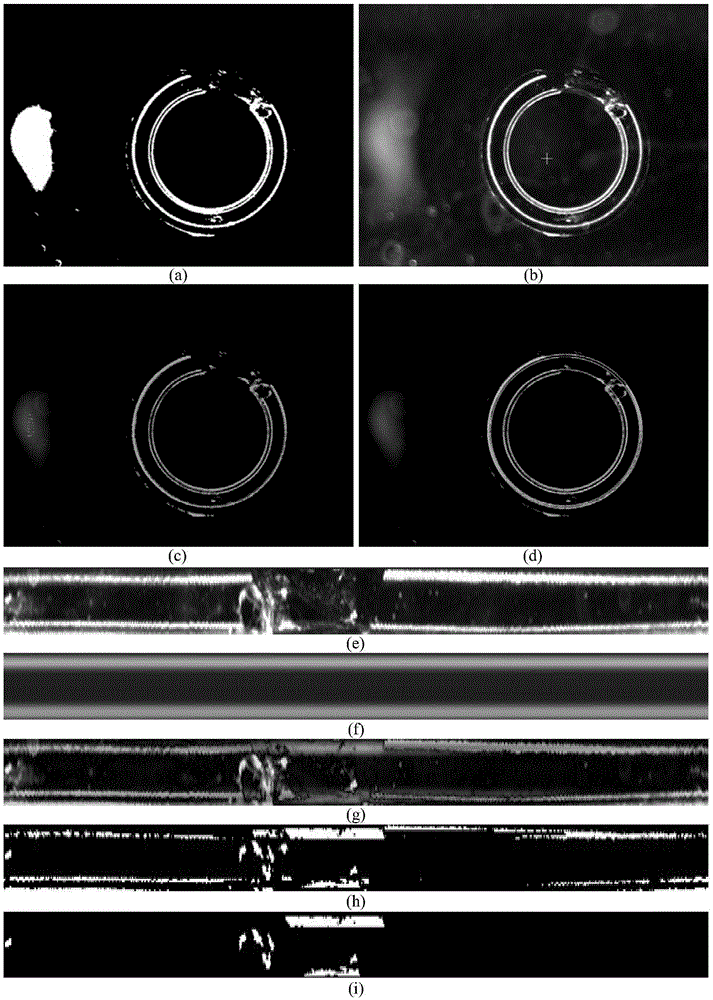

[0081] Firstly, through the global threshold segmentation, center of gravity method, radial scanning, and circle fitting to achieve high-speed and accurate positioning of the bottle mouth, then divide the bottle mouth into three detection areas, and use the center of the bottle mouth as the polar coordinate origin to perform polar coordinate transformation and expansion.

[0082] 1.1 Global threshold segmentation to obtain the edge area of the bottle mouth

[0083] Take the upper left corner of the image as the coordinate origin, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com