Manufacturing method of wires applied to wearable device

A wire manufacturing method and wearable device technology, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of insufficient elasticity, hard wires, discomfort, etc., and achieve the effect of good elasticity and comfortable fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

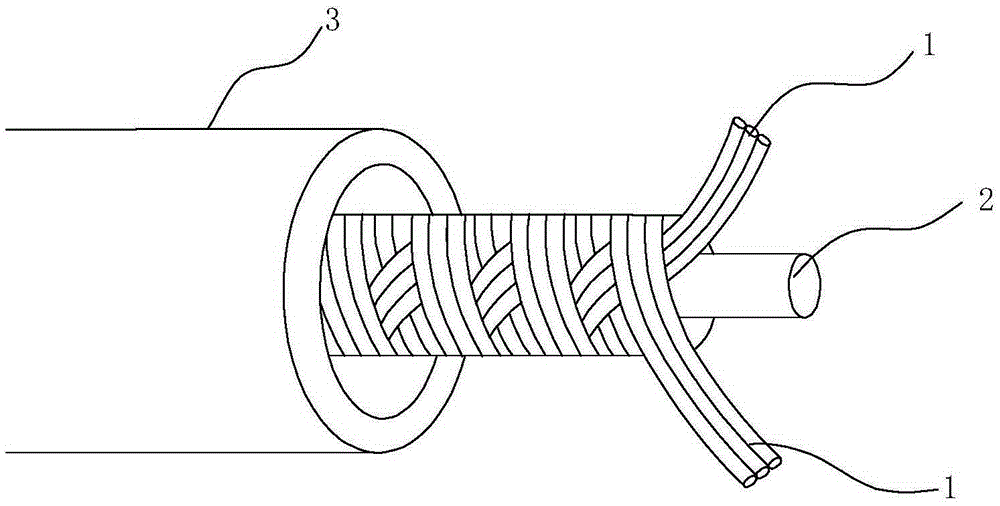

[0017] see figure 1 , a method for manufacturing electric wires applied to wearable devices, comprising the steps of:

[0018] 1) Preparation of electric wire substrate: chemically silver-plate the surface of the nylon filament to obtain the silver-plated wire 1, and measure the length resistivity of the silver-plated wire 1. Preferably, the nylon filament is 110D, double-strand, and the silver-plated wire 1 It has a certain degree of elasticity, but also has good washing resistance;

[0019] 2) Twisting and combining: According to the length resistivity obtained in step 1), the number of silver-plated wires 1 that meet the impedance requirements of the final application wearable device needs to be combined, the length resistivity, and the root of the silver-plated wire are calculated. The functional relationship between the number and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com