Fabrication method of flexible substrate, fixing method and fixing structure

A technology of flexible substrates and manufacturing methods, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of increased cost of release layer 22, increased manufacturing process difficulty, complex structure, etc., to achieve increased separation The effects of layer cost, process simplification, and process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

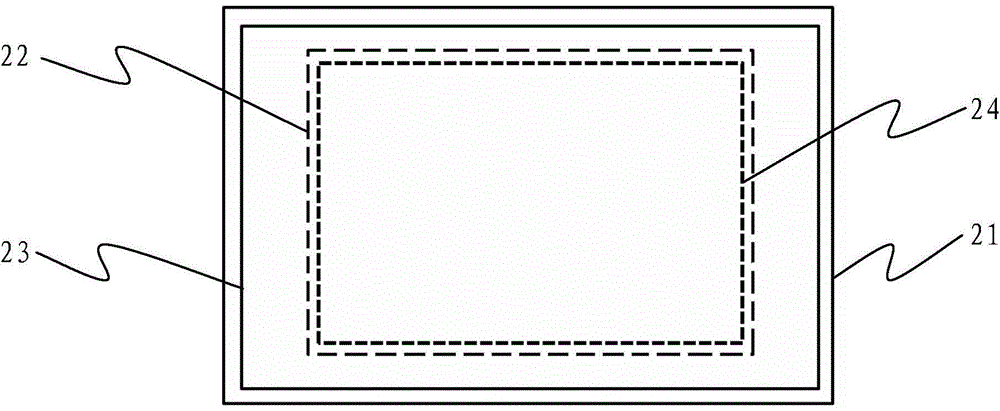

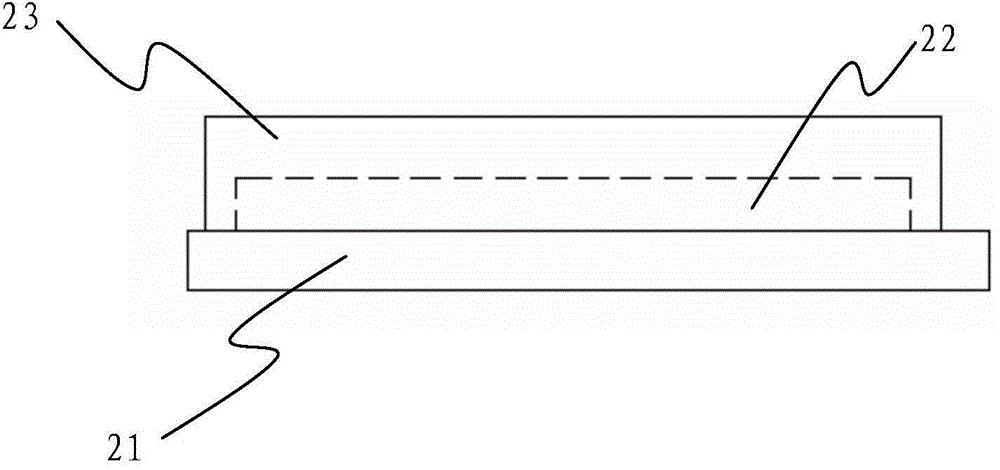

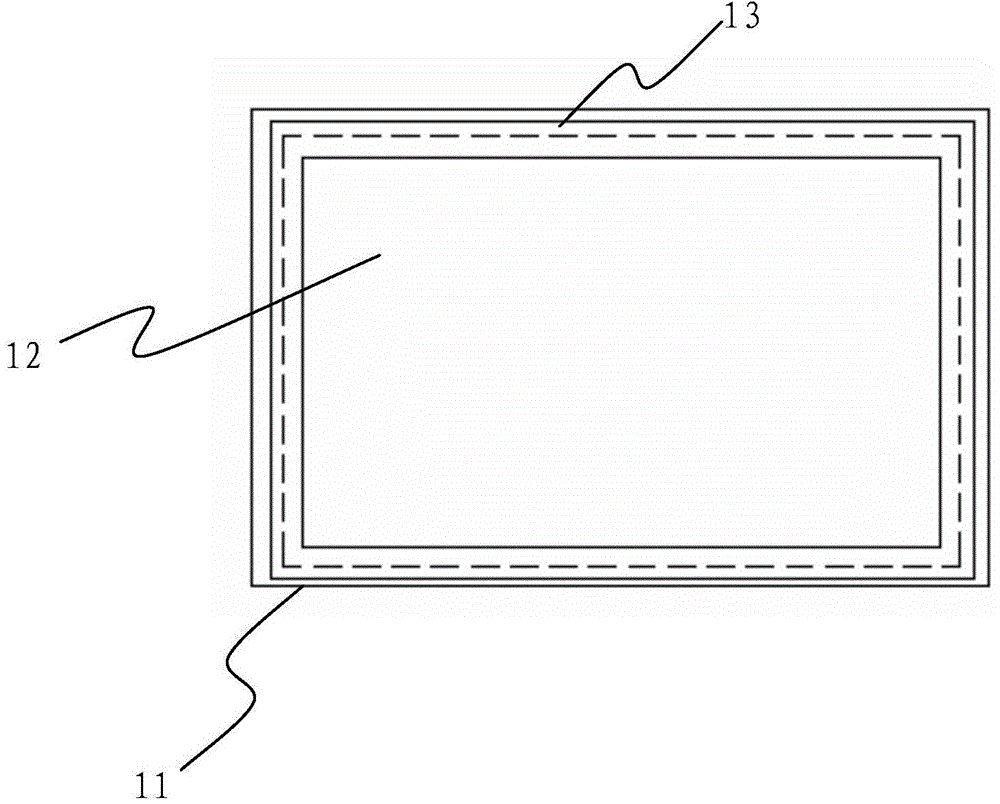

[0028] refer to Figure 3 ~ Figure 8 As shown, the present invention discloses a fixing structure for a flexible substrate, including a glass carrier 11 and a flexible substrate 12, the flexible substrate 12 is attached to the glass carrier 11, and the material of the flexible substrate 12 is a weak glass adhesive material, Including PEN (abbreviation for polyethylene naphthalate), PEP (phosphoenolpyruvate), PI (polyimide film) and its derivatives. The edge of the flexible substrate 12 is coated with a strong glass adhesive material 13 to fix the flexible substrate 12 on the glass carrier 11. The strong glass adhesive material 13 is a high temperature resistant material, and the use of a high temperature resistant material can reduce the temperature in the subsequent high temperature TFT process. Its own gas volatilization, and can f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com