A printed high-resolution display device and its manufacturing method

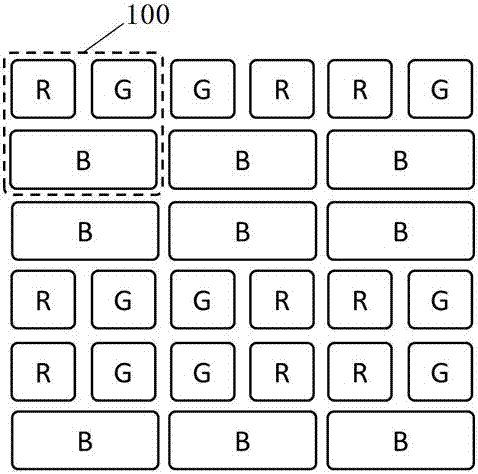

A technology with high resolution and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problem that the printing process is difficult to further improve the display resolution, etc., to reduce the area and increase the deposition area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

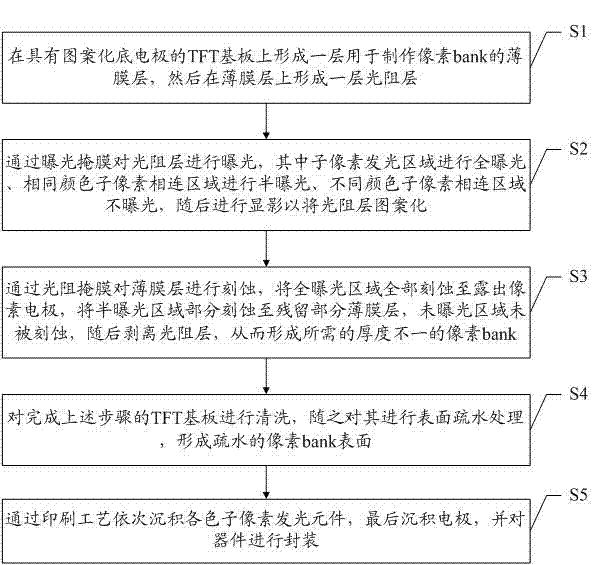

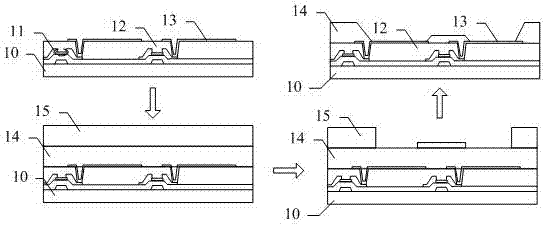

[0036] A method for manufacturing printed high-resolution display devices, combining figure 2 with image 3 As shown, it includes the steps:

[0037] S1. A thin film layer 14 for making a pixel bank is formed on the TFT substrate 10 with a patterned bottom electrode 13 (there is a TFT array 11, a passivation flat layer 12 and a patterned bottom electrode 13), and then a thin film layer 14 for making a pixel bank is formed on the thin film A photoresist layer 15 is formed on the layer 14;

[0038] S2. Expose the photoresist layer 15 through an exposure mask, where the light-emitting area of the sub-pixels is fully exposed, the connected area of the sub-pixels of the same color is half exposed, and the connected areas of the sub-pixels of different colors are not exposed, and then the photoresist layer is developed. 15 patterning; full exposure is to completely remove the photoresist layer 15, half exposure is to partially remove the photoresist layer 15 to retain a thin layer o...

Embodiment 2

[0045] A method for manufacturing printed high-resolution display devices, combining Figure 4 with Figure 5 As shown, it includes the steps:

[0046] T1. On a TFT substrate 20 with a patterned bottom electrode 23 (in this embodiment, a labeling method different from that in Embodiment 1 is used to distinguish) (there is a TFT array 21, a passivation flat layer 22 and a patterned bottom electrode 23) A photoresist layer 24 for making a pixel bank is formed on it;

[0047] T2. Expose the photoresist layer 24 through the exposure mask, wherein the light-emitting area of the sub-pixels is fully exposed, the connected area of the same color sub-pixels is half exposed, and the connected area of the different color sub-pixels is not exposed;

[0048] T3. Subsequent development processing is performed to completely remove the photoresist layer 24 in the fully exposed area, exposing the patterned bottom electrode 23, partially remove the photoresist layer 24 in the half exposed area, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com