Imaging device and assembly method thereof

A technology of an imaging device and an assembly method, applied in the optical field, can solve the problems of increasing the size of a camera module and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

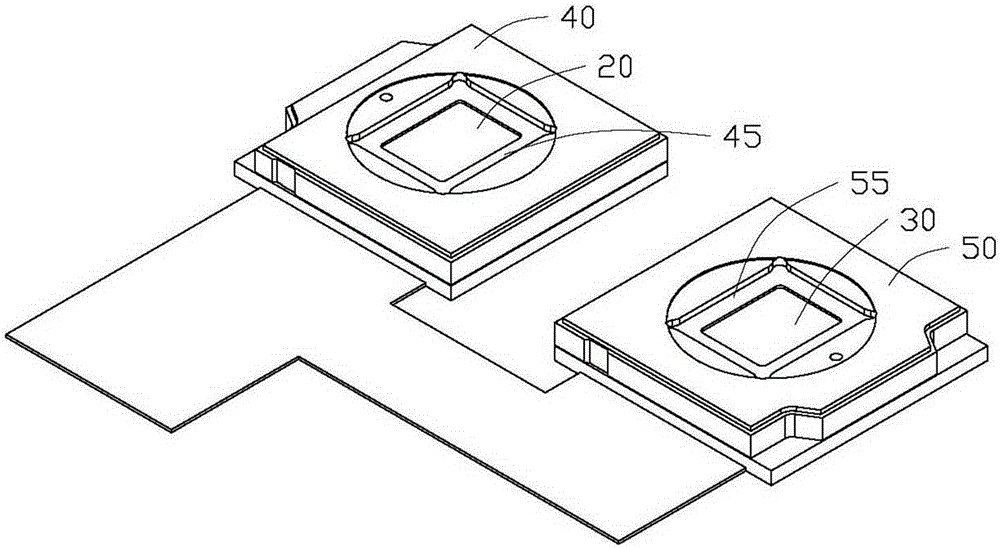

[0018] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] see Figure 1 to Figure 6 , the method for assembling the imaging device 100 according to the first embodiment of the present invention includes the following steps:

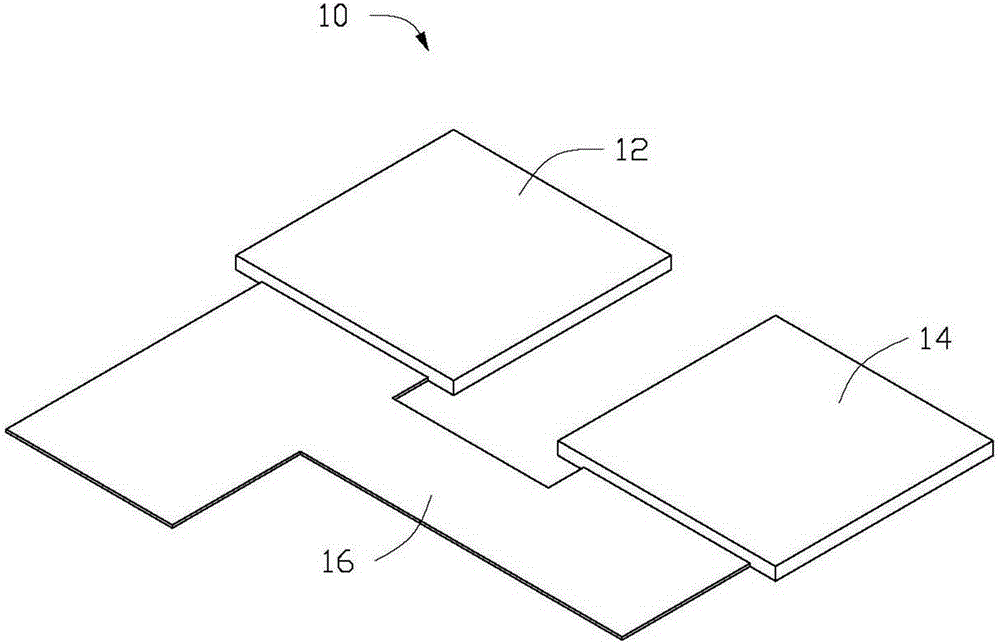

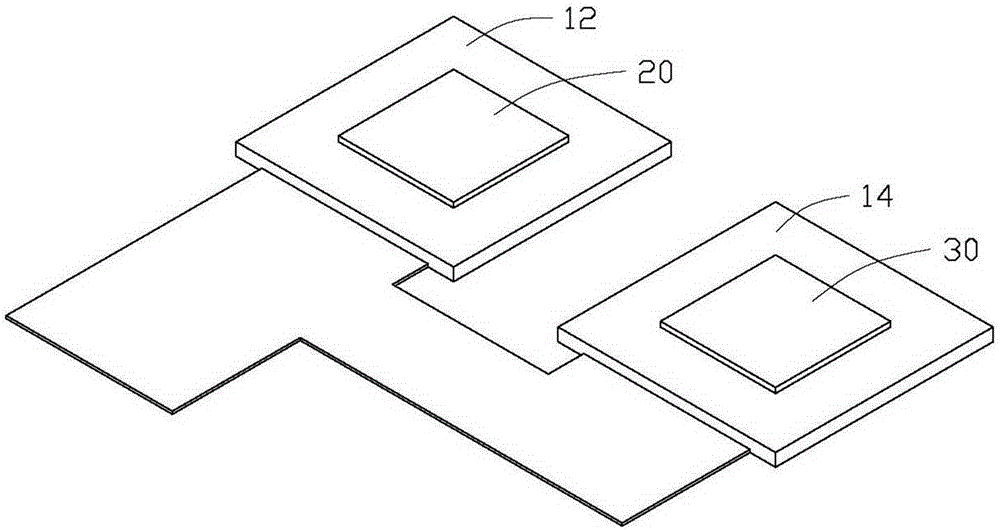

[0020] For a first step, see figure 1 , providing a flexible circuit board 10 .

[0021] The flexible circuit board 10 includes a first portion 12 , a second portion 14 and a connecting portion 16 . The shape and size of the first part 12 and the second part 14 are the same. In this embodiment, the first portion 12 and the second portion 14 are square. The first portion 12 and the second portion 14 are arranged in parallel and spaced apart, and the connecting portion 16 is used for connecting the first portion 12 and the second portion 14 . And the connecting portion 16 is connected to the same side of the first portion 12 and the second portion 14 .

[0022] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com