Pipette gun with rotating and replacing tip

A technology of pipetting gun and pipette tip, which is applied in the direction of measuring tube/pipette, laboratory container, laboratory utensil, etc. Mistake reagents, ensure the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

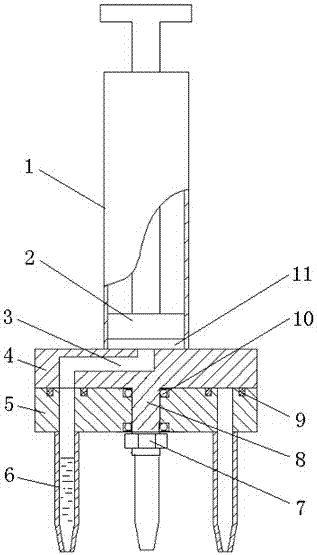

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The liquid pipette that the present invention provides for rotating and replacing the gun head includes a gun body 1 with a piston chamber 11 in it, a gun body 1 with a piston 2 in the piston chamber 11, and a gun head located at the lower end of the gun body 1, and the gun head includes The fixed part 4 that links to each other with the gun body 1, the rotating part 5 that matches with the fixed part 4, the described fixed part 4 is provided with the vent hole 3, and this vent hole 3 communicates with the piston chamber 11 of the gun body 1, and the rotating part 5 The part 5 is provided with a plurality of penetrating gun heads 6, and the air hole 3 on the fixed part 4 extends from the middle part of the fixed part 4 to the side and the lower part, that is, the inner upper end of the air hole 3 is located at the top of the fixed part 4, and is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com