Led core column guide wire short leg automatic dial 45 degrees device

A forty-five-degree, toggle device technology, applied to other household appliances, household appliances, applications, etc., can solve the problems of high defective rate, high labor intensity of workers, and low efficiency, so as to improve production efficiency and improve dialing efficiency. The effect of foot craft efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

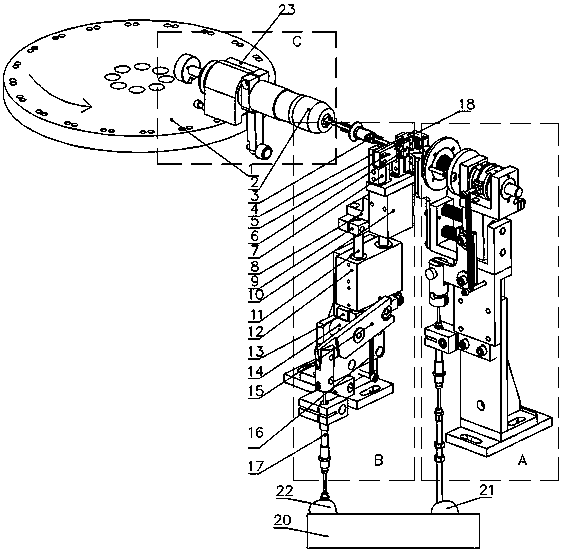

[0021] The main function of the short pin dialing 24 degree assembly of this device is to dial 4 short metal pins of the stem 3 into a shape of about 90 degrees mutually.

[0022] In the gap divider, the input shaft rotates continuously for one circle, and the output shaft can be used as a mechanism for stopping and rotating. The desired action can be completed during the stop period. The input shaft of the gap divider is connected with the motor through a belt, a reducer, a main shaft, and a sprocket chain.

[0023] As shown in Figure 1, the indexing disk has been reduced for the convenience of display. The indexing disk 1 is fixed on the output shaft end of the divider, and the gap divider, the short leg dial 24 degree mechanism (in the rectangular frame C) and the stem left and right positioning mechanism (in the rectangular frame B) are all fixed on the platen. Such as figure 1 , the stem is clamped in the stem clamp 2 (in the rectangular frame C), the upper stem clamp ...

Embodiment 2

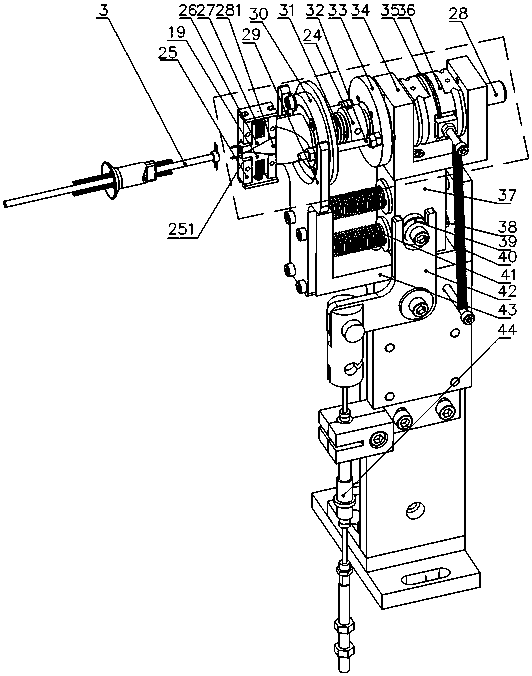

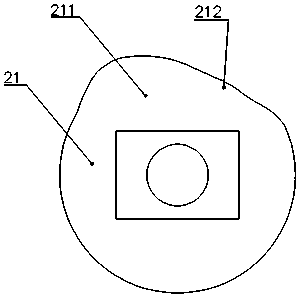

[0031] Such asfigure 1 As shown, the LED stem guide wire short leg automatic dialing device for 45 degrees is used to dial the four short metal legs connected to the stem 3 to make about 90 degrees to each other, including the connection on the indexing disc in turn. The clamping device 2, gap divider 23, stem positioning device and toggle device on 1; the stem positioning device and toggle device are respectively connected to the same transmission shaft 20 through a positioning and transmission cam 22, 21 for coordinated rotation , wherein: stem positioning device: including positioning chuck 5 concentric with clamping device 2, cylinder seat 8, slide rail seat 9, cylinder 10, guide post 11, positioning slider 12, guide rail seat cam 13, rocker arm 15 , thick pull wire 17, cylinder 10 is connected in cylinder block 8 and drives positioning chuck 5 to clamp or unclamp core post 3; Slide rail seat 9 is located at the bottom of cylinder block 8 to be located at its vertical direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com