Hydraulic control system and front rear-driving hydraulic automatic gearbox comprising system

A technology of hydraulic control system and hydraulic torque converter, which is applied in the direction of vehicle gearbox, transmission device control, transmission components, etc., can solve the problems of increasing manufacturing cost, increasing the structural size of the gearbox, and complex logic of the gearbox hydraulic control system. , to achieve the effect of improving shifting quality and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

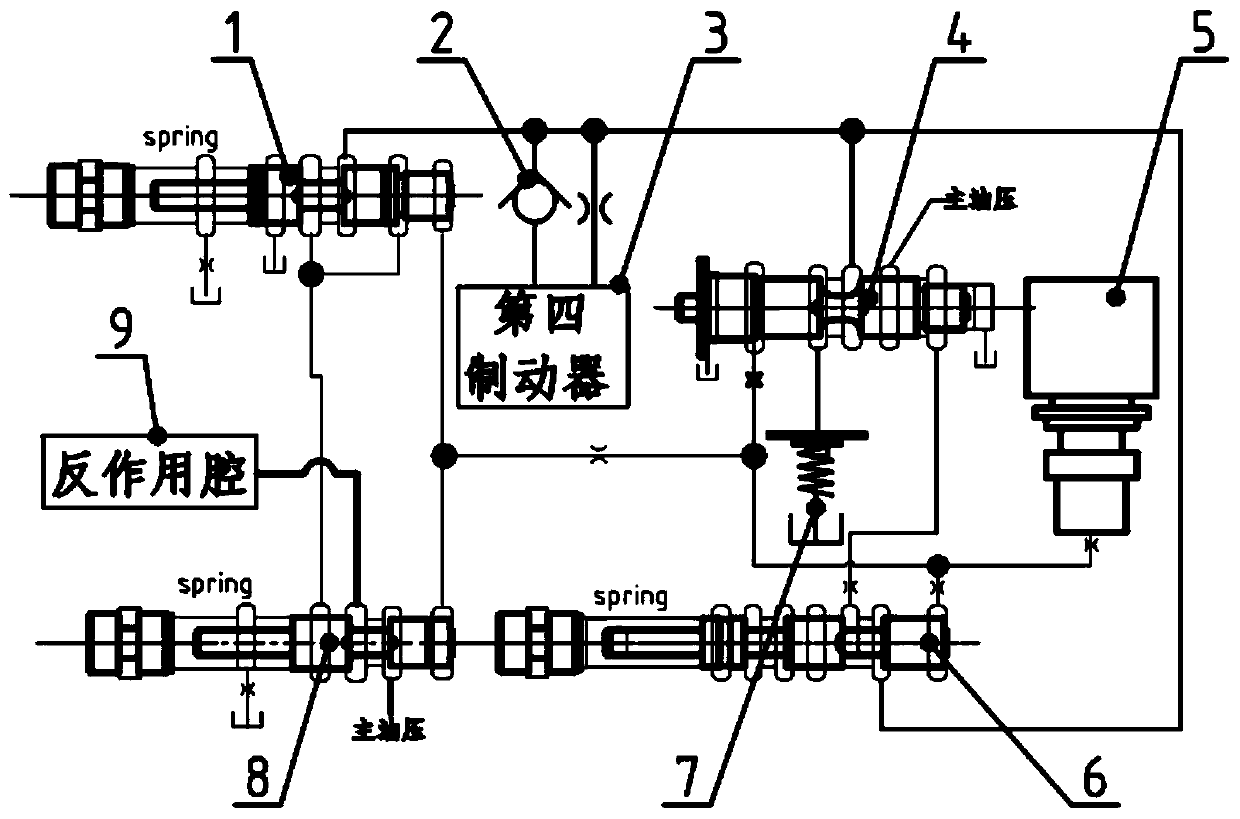

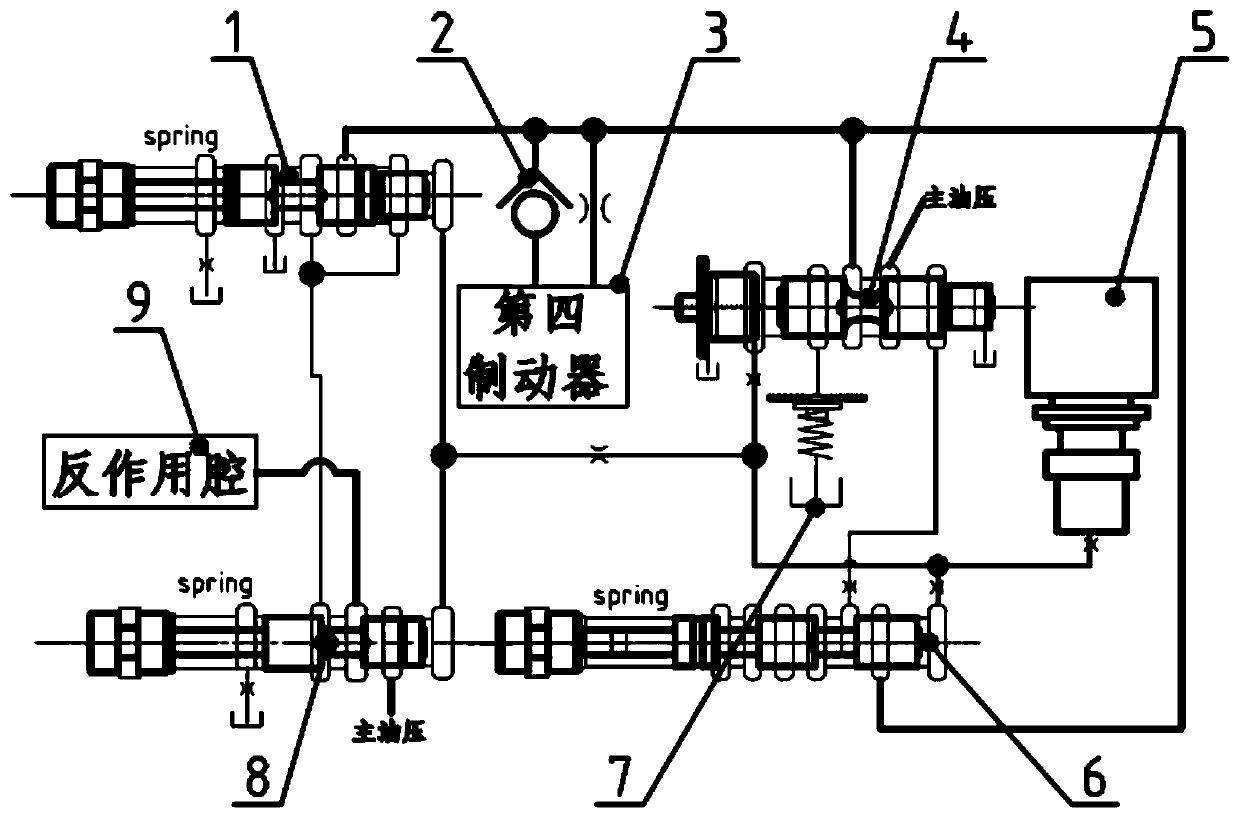

[0019] The hydraulic control system of this embodiment and the corresponding downshifting strategy, the hydraulic control system is composed of a high-pressure oil circuit, a gear switching oil circuit, a lock-up separation oil circuit and a lubricating oil circuit. The main functions of this hydraulic system are:

[0020] 1. By controlling the switching states of 5 hydraulic actuators (the first clutch, the second clutch, the third brake, the fourth brake, and the fifth clutch), the switching of P / R / N / D gears is realized, and the D gear is divided into D1 / D2 / D3 / D4 / D5 / D6 six gears.

[0021] 2. According to different working conditions, control the switching between the locking / unlocking states of the hydraulic torque converter. It is in the unlocked state when starting / climbing and other working conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com