Datum transformation fixture and datum transformation method for guide blades

A technology of guide vane and reference conversion, which is applied to rotors, kitchen utensils, heat exchange equipment, etc., can solve problems such as scrapping and out-of-tolerance, and achieve the effect of ensuring pouring accuracy and improving processing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

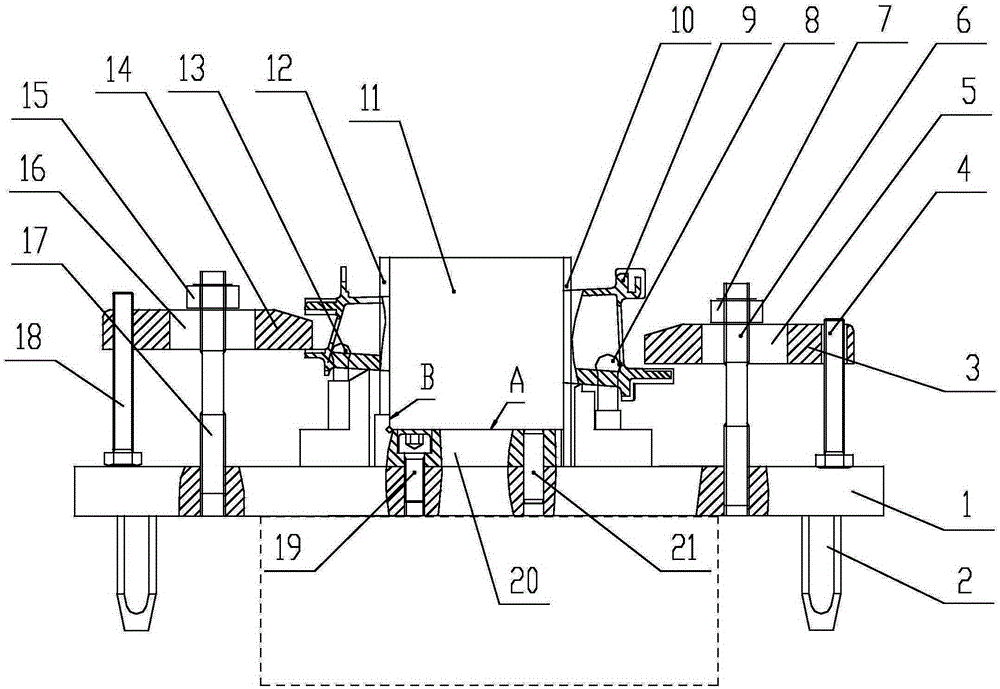

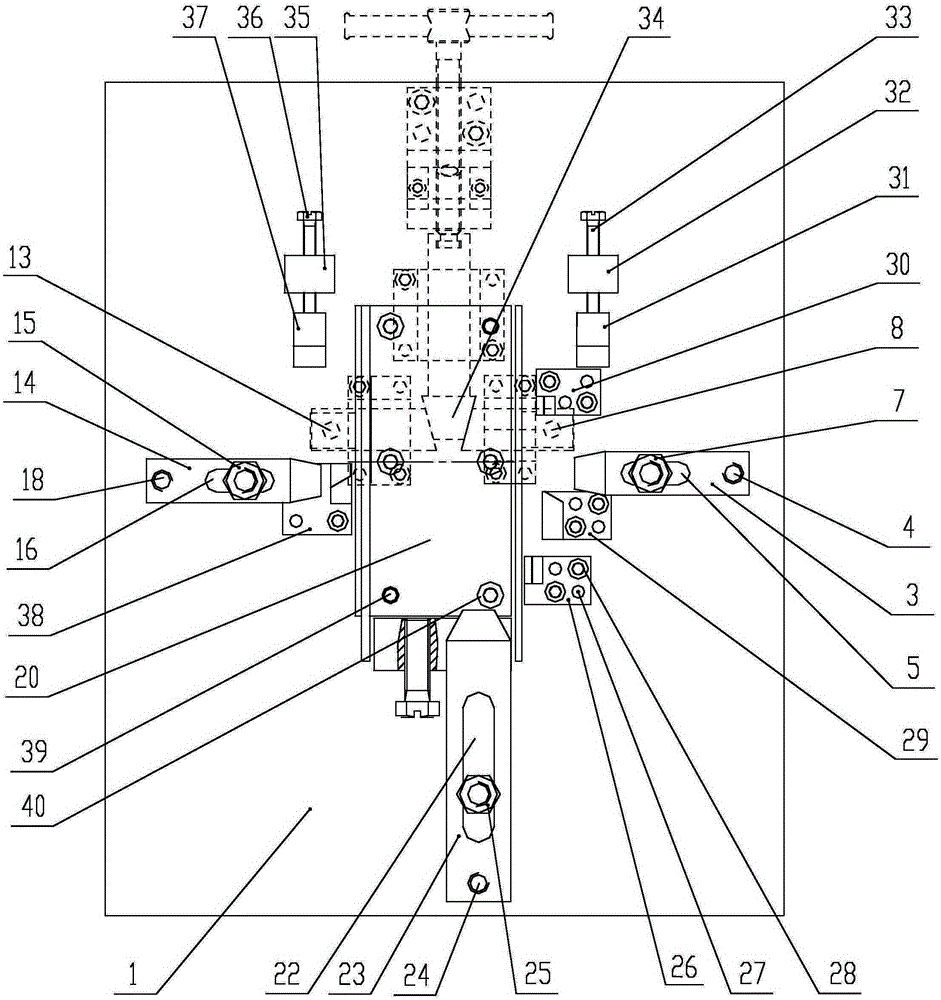

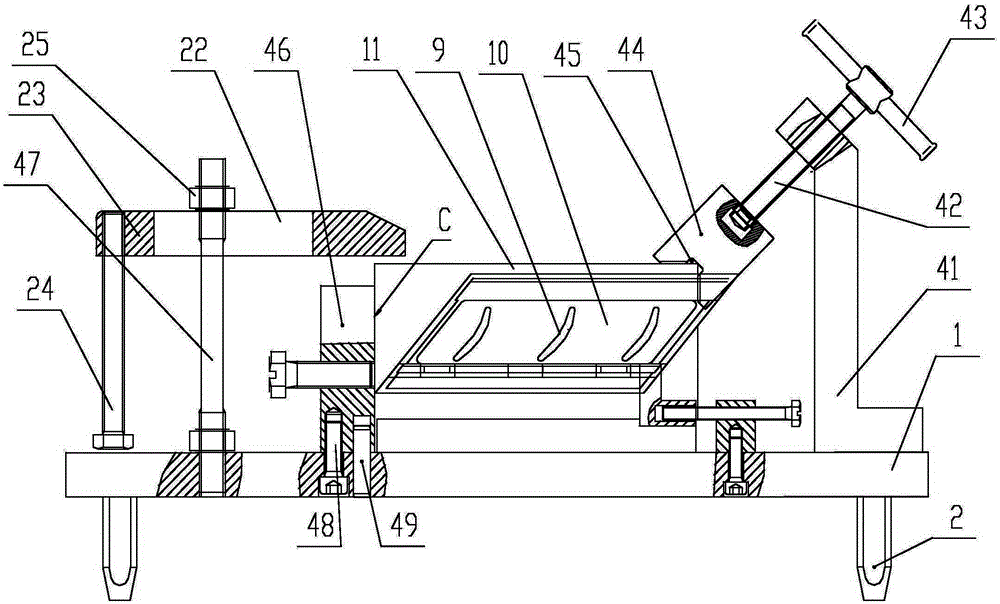

[0046] In this embodiment, a three-unit cast low-guide vane is taken as an example, and the wool positioning points are A1, A2, A3, B4, B5, F6, and F7, such as Figure 10 shown. Among them, the positioning point A1 is the positioning point where the basin moves toward the first blade close to the upper mounting plate exhaust side to the R exhaust side, and the positioning point A2 is the basin moving toward the first blade close to the upper mounting plate exhaust side to transfer the R exhaust side Side positioning point, positioning point A3 is the basin to the second blade close to the exhaust side of the lower mounting plate to transfer to R exhaust side positioning point, positioning point B4 is the basin to the second blade close to the upper mounting plate exhaust side to transfer to R The positioning point on the side of the pot, the positioning point B5 is the positioning point on the side of the basin where the pot is connected to the second blade close to the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com