Rotary table of gravity casting machine

A technology of gravity casting machine and rotating platform, which is applied to casting equipment, manufacturing tools, equipment for feeding molten metal into molds, etc., can solve problems affecting the quality of workpieces, and achieve safe and stable rotation, and easy removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

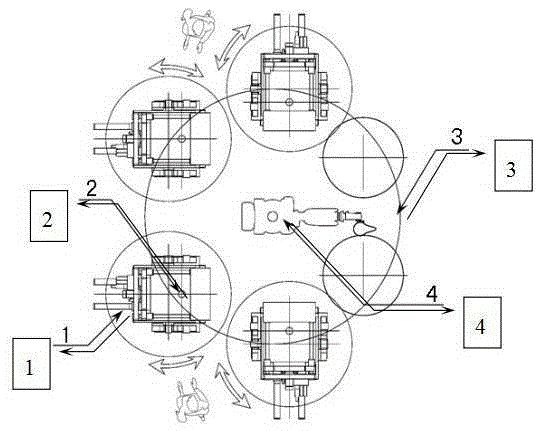

[0012] Depend on figure 1 Known, a schematic diagram of the workpiece pouring forming area composed of four gravity casting machines and robots. One robot 4 and four gravity casting machines 1 operate intermittently, and during the operation of each robot 4 , personnel are prohibited from entering in the robot movement area 3 . In this figure, two gravity casting machines form a group and rotate relative to each other. After each gravity casting machine 1 completes the forming process of a workpiece, a layer of aluminum will be left in the mold sprue cup position 2 where the molten aluminum is poured. Skin, this aluminum skin needs to be removed.

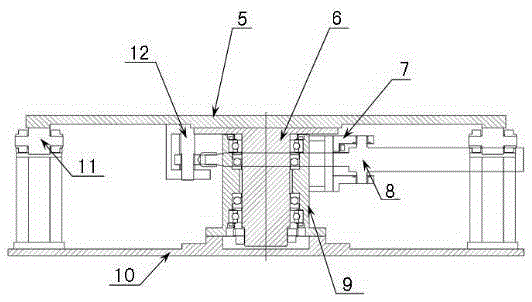

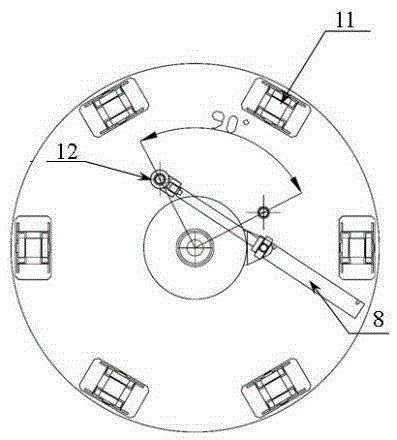

[0013] Depend on figure 2 It is an embodiment of the present invention. A gravity casting machine turntable, composed of a rotating platform 5, a rotating shaft 6, an oil cylinder fixing seat 7, a driving oil cylinder 8, a fixed bushing 9, a fixed base 10, a supporting drum 11 and a driving fulcrum 12, the fixed bushing 9 Fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com