Electron beam composite narrow gap mag welding method for large thickness martensitic heat-resistant steel separator

A welding method and electron beam welding seam technology, which is applied in the field of electron beam composite narrow gap MAG welding of large-thickness martensitic heat-resistant steel partitions, can solve the problems of difficult to guarantee welding quality, difficulty in obtaining satisfactory weld seam, and difficulty in weld seam formation To achieve the effect of improving welding quality, shortening welding operation time, and reducing weld seam offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

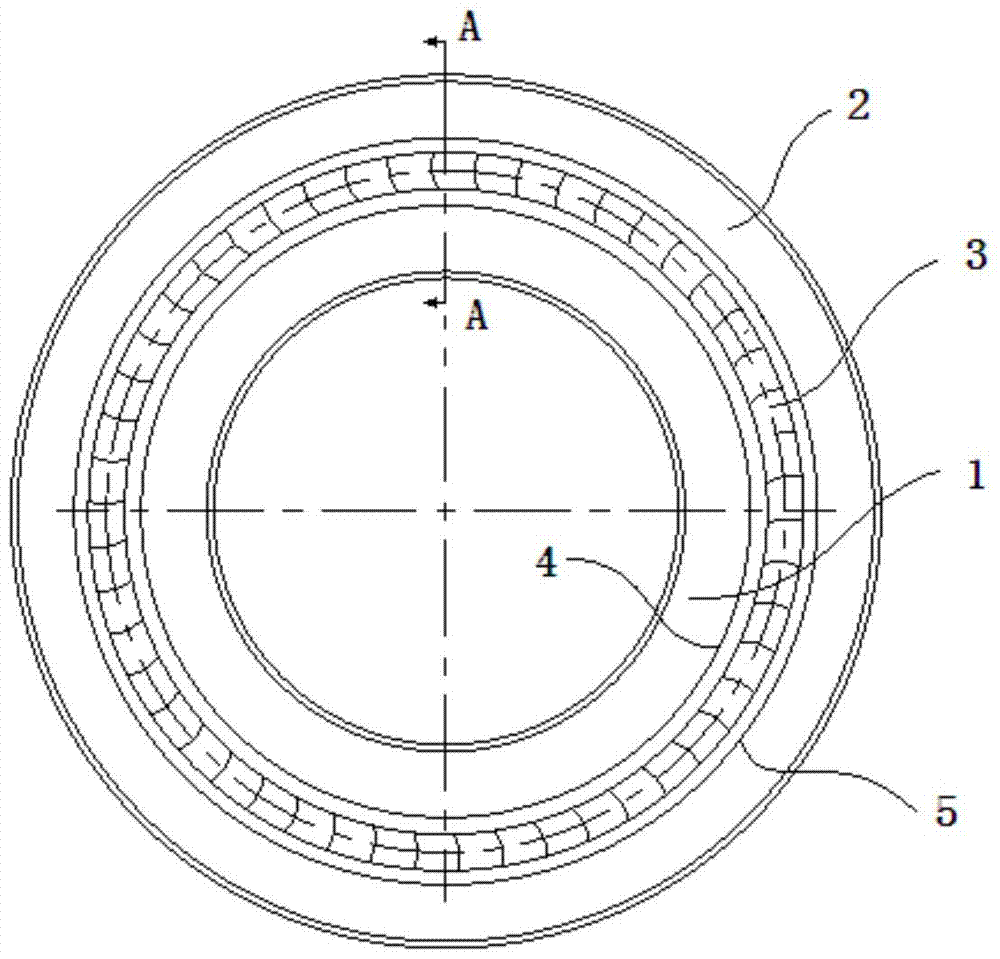

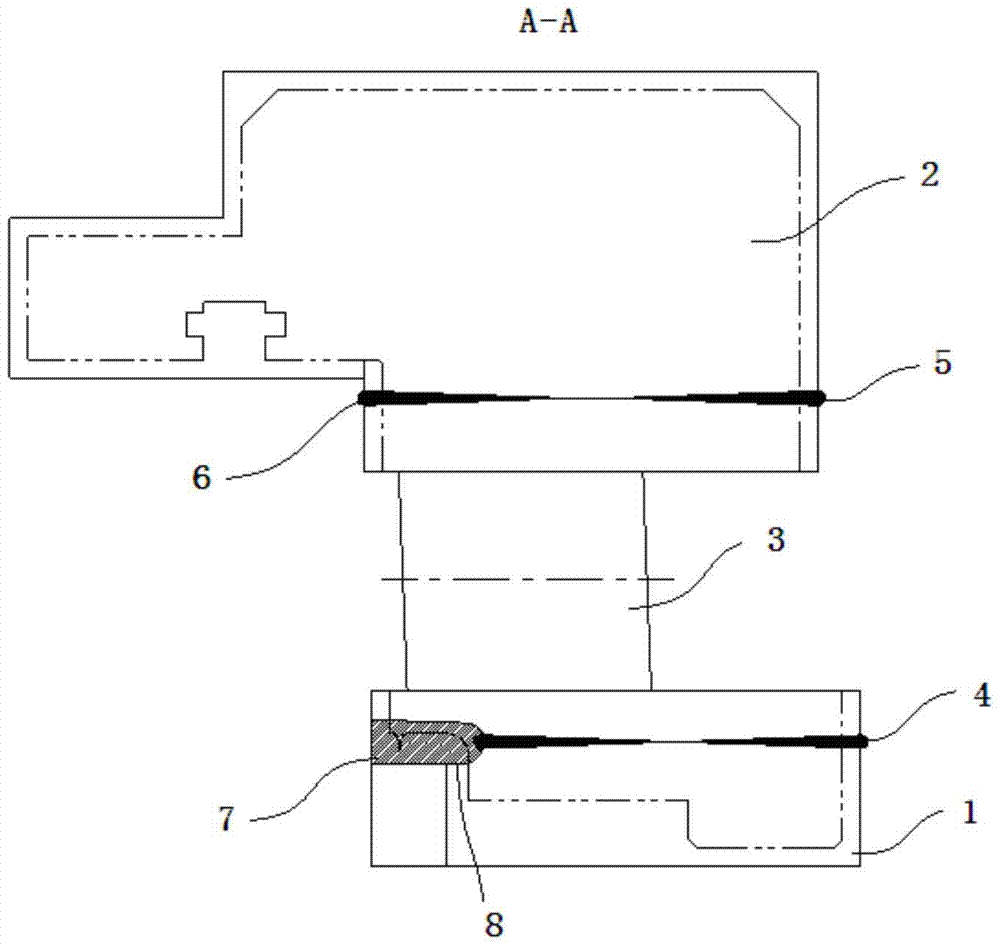

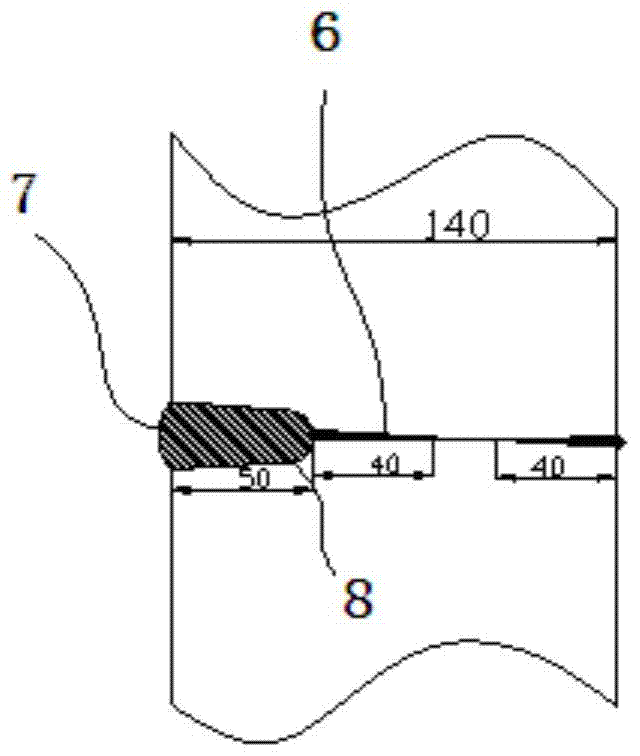

[0028] Such as figure 1 , figure 2 and image 3 As shown, the electron beam composite narrow-gap MAG welding method for large-thickness martensitic heat-resistant steel separators includes the following steps:

[0029] 1) According to the total depth of the main welding seam of the partition is 140mm, allocate the depth of the electron beam welding seam 6 and the narrow gap welding seam 7 to ensure that the depth of the electron beam welding seam 6 is 40mm, and distribute at the same time on both sides. A 50mm narrow gap and a deep U-shaped groove 8 are opened on the outer side of the beam weld 6;

[0030] 2) Assemble the diaphragm body 1, cascade 3 and diaphragm outer ring 2 on the assembly platform, adjust the gap to meet the design requirements, and clamp it with tooling to ensure that the diaphragm body 1, cascade 3 and diaphragm outer ring 2 are relatively fixed ;

[0031] 3) Detect the residual magnetism within 5mm of the inner and outer circle of the part to be wel...

Embodiment 2

[0040] Such as figure 1 , figure 2 and Figure 4 As shown, a large-thickness martensitic heat-resistant steel separator electron beam composite narrow-gap MAG welding method includes the following steps:

[0041] 1) According to the total depth of the main welding seam of the partition is 210mm, the depth of the electron beam welding seam 6 and the narrow gap welding seam 7 is allocated to ensure that the depth of the electron beam welding seam 6 is 50mm, and both sides are allocated at the same time. Deep U-shaped grooves 8 with narrow gaps of 50mm are respectively opened on the outer sides of the electron beam welds 6;

[0042] 2) Assemble the diaphragm body 1, cascade 3 and diaphragm outer ring 2 on the assembly platform, adjust the gap to meet the design requirements, and clamp it with tooling to ensure that the diaphragm body 1, cascade 3 and diaphragm outer ring 2 are relatively fixed ;

[0043] 3) Detect the residual magnetism within 5mm of the inner and outer circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com