Astatic laser coding machine and coding method

A laser coding machine and laser coding technology, applied in the field of laser coding, can solve the problems of uncertain coding position and angle, and achieve the effect of precise laser coding, improving production efficiency and coding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

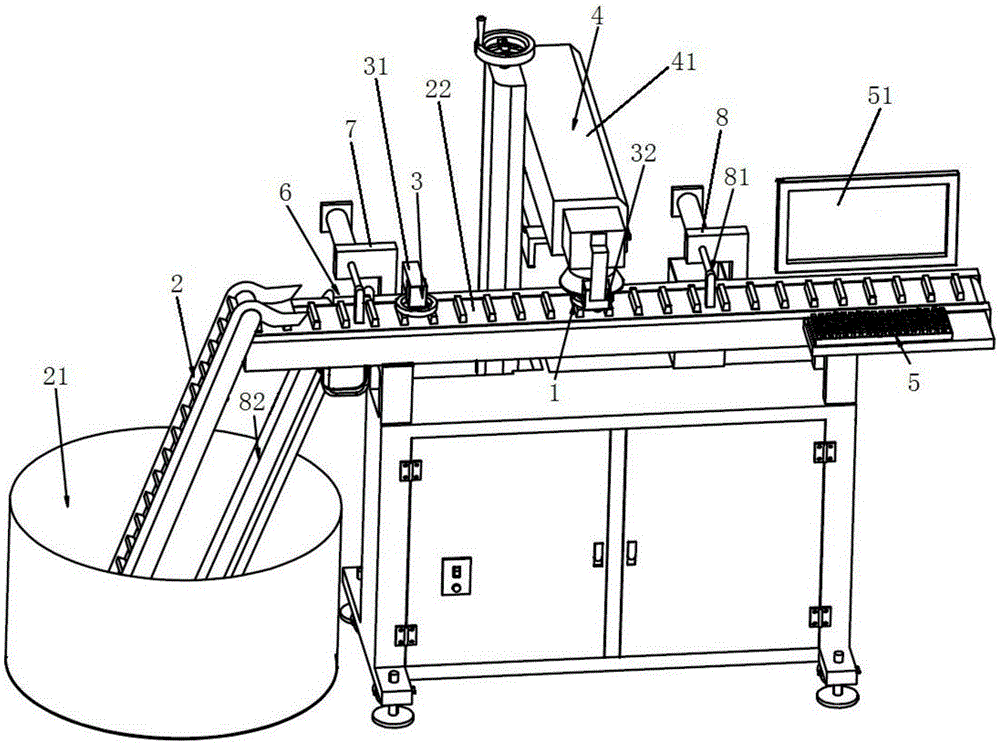

[0022] Such as figure 1 As shown, a non-directional laser coding machine includes a frame 1, a feeding system 2, a visual recognition system 3, a laser coding system 4, and a control system 5. The feeding system 2 includes a product container 21 and a product conveyor belt 22 for The product 6 is fed and the product 6 is conveyed on the frame 1, and the product sensor 7 is provided at the front end of the product conveyor belt 22; the visual recognition system 3 and the laser coding system 4 are set above the frame 1, and the visual recognition system 3 includes front and back visual The collector 31 and the non-directional visual collector 32 are used to capture product images, compare them with standard images, and calculate the offset of the position and angle of the current product. The laser marking system 4 has a laser marking machine 41 for Obtained product offset coordinates and angles, adjust the position of the product 6 and code the product 6, the control system 5 i...

Embodiment 2

[0025] A non-directional laser marking method, comprising the steps of:

[0026] (1) The product is transported by the feeding system into the coding area of the rack;

[0027] (2) The control system receives the trigger signal from the product sensor and sends processing instructions to the visual recognition system;

[0028] (3) The visual recognition system performs processing, including capturing the product image, comparing it with the standard image, and calculating the position and angle offset of the current product, and the visual recognition system sends the processing result back to the control system;

[0029] (4) The control system processes the acquired data, including converting the offset based on the visual coordinate system and converting it into a coordinate value based on the laser marking system;

[0030] (5) The control system sends a coding request to the laser coding system;

[0031] (6) The laser marking system moves the object position in the codi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com