Tube body supporting structure used for tube body cutting device

A technology of cutting device and supporting structure, applied in the direction of positioning device, support, clamping, etc., can solve the problems of bracket pressure deviation, sliding sleeve stuck on the column, affecting production or cutting efficiency, etc., and achieve smooth lifting and moving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

[0017] The left and right directions in this specification refer to the left and right directions when viewed along the direction in which the pipe body moves.

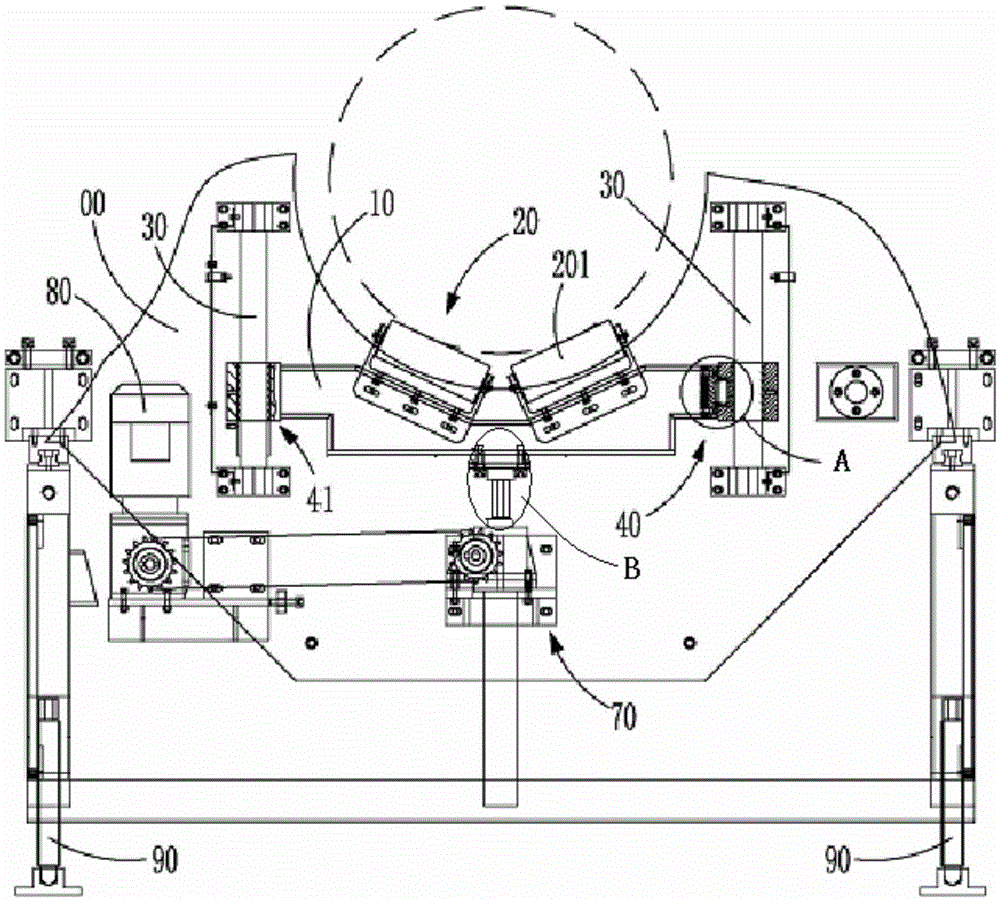

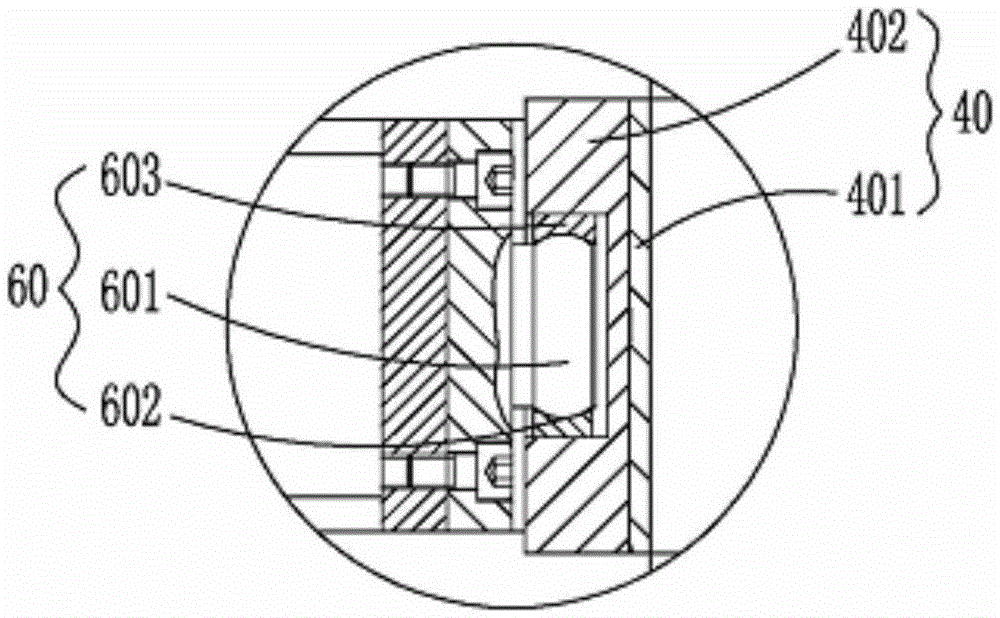

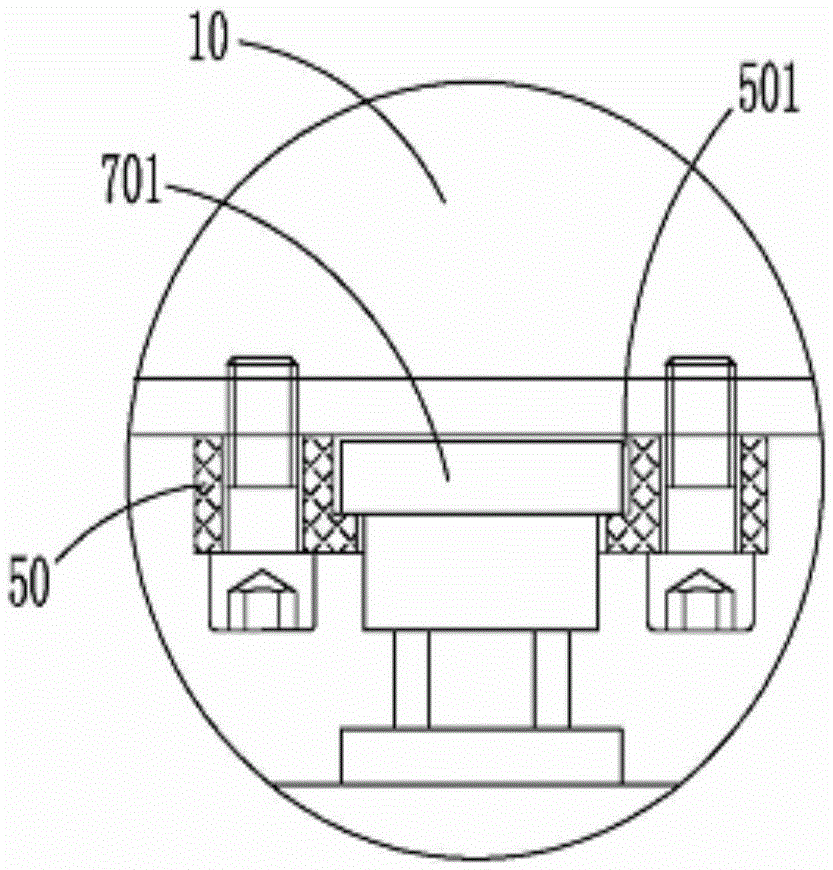

[0018] as attached figure 1 , 2 As shown, a pipe body support structure used by a pipe body cutting device includes a frame 00, a bracket 10 that can be lifted and lowered on the frame 00, and a bracket 10 that is set on the bracket 10. The idler assembly 20 supporting the pipe body, the frame 00 is provided with two guide columns 30 along the vertical direction, and the left and right sides of the bracket 10 are respectively provided with guide columns capable of moving along the corresponding guide columns. 30 moves the first sliding sleeve 40 and the second sliding sleeve 41, the first sliding sleeve 40 or the second sliding sleeve 41 is connected to the bracket 10 through...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap