A kind of preparation method of high-purity human coagulation factor VIII

A human coagulation factor, high-purity technology, applied in the preparation method of peptide, coagulation/fibrinolysis factor, factor VII, etc., can solve the problems of decreased coagulation effect, low specific activity and low specific activity of FVIII, etc., and improve the safety of use. properties, avoid protein damage, and reduce the effect of denaturation and inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

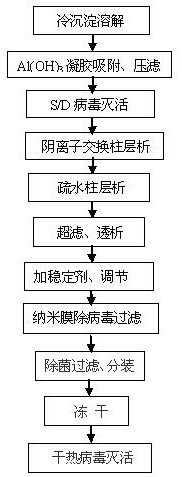

Image

Examples

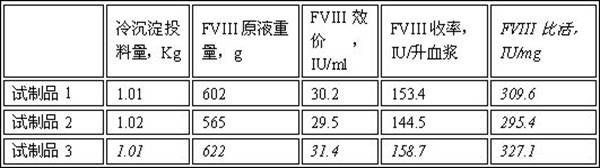

Embodiment 1

[0029] 1. Cryoprecipitate dissolution: put 1kg cryoprecipitate into 5kg dissolution buffer (0.02M TRIS-HCL, 0.1MNacL, glycine 1.5% (wt%), PH6.50-6.60), add heparin to the dissolution buffer in advance to 2000IU / kg, the temperature is controlled at 15-20°C, and stirred for 3 hours to fully dissolve;

[0030] 2. Al(OH)3 adsorption and pressure filtration: Add 0.6kg of Al(OH)3 gel to the above solution, stir thoroughly for 1 hour, then filter with Supradur 50P filter plate produced by Pall Company in series with 1.0μm filter element, Collect the clarified filtrate, and pre-wash the filter plate and filter element with the dissolution buffer described in step 1 before filtering;

[0031] 3. S / D virus inactivation: Add Tween80 to 1.0% (wt%) and TNBP (tributyl phosphate) to 0.3% (wt%) to the above filtrate, stir well, heat up to 24-26°C, and keep warm for 6 hours, then clarify and filter with a 0.45μm filter element;

[0032] 4. Anion-exchange column chromatography: the filtrate ...

Embodiment 2

[0041] 1. Cryoprecipitate dissolution: Put 1 kg of cryoprecipitate into 10 μL dissolution buffer (0.02M TRIS-HcL, glycine 0.5%, (wt%), 0.1M NaCL, PH7.30-7.40), pre-added to the dissolution buffer Heparin to 10000IU / kg, temperature controlled at 25-30°C, stirred for 1.5 hours to fully dissolve;

[0042] 2, Al(OH)3 adsorption and pressure filtration: add 1.65kg of Al(OH)3 gel to the above solution, stir thoroughly for 1.5 hours, then filter with Supradur 50P filter plate produced by Pall Company in series with 1.0μm filter element, Collect the clarified filtrate, and pre-wash the filter plate and filter element with the dissolution buffer described in step 2 before filtering;

[0043] 3, S / D virus inactivation: with embodiment one;

[0044] 4. Anion-exchange column chromatography: the filtrate after virus inactivation is put on Capto DEAE column, and the column is fully equilibrated with equilibration buffer in advance. ),0.0l5M CaCl 2 , PH7.30-7.40; after loading the column...

Embodiment 3

[0050] 1, Cryoprecipitate dissolution: put 1kg cryoprecipitate into 7kg dissolution buffer (0.02M TRIS-HCL, 0.15MNaCL, glycine 1.0% (wt%), PH6.90-7.10), add heparin to the dissolution buffer in advance to 6000IU / kg, the temperature is controlled at 20-25 ℃, stirred for 2 hours to fully dissolve;

[0051] 2, Al(OH)3 adsorption and pressure filtration: add 0.7kg of Al(OH)3 gel to the above solution, stir thoroughly for 0.5 hours, then filter with Supradur 50P filter plate produced by Pall in series with 1.0μm filter element, Collect the clarified filtrate, and pre-wash the filter plate and filter element with the dissolution buffer described in step 2 before filtering;

[0052] 3, S / D virus inactivation: with embodiment one;

[0053] 4. Anion exchange column chromatography: the filtrate after virus inactivation was put on Q SePharose 4FF column, and the column was fully equilibrated with equilibration buffer in advance. wt%) , 0.01M CacL2 , PH6.90-7.10; after loading the colu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com