Automatic yarn feeding device for mercerizing machine and operating method thereof

A kind of mercerizing machine, automatic technology, applied in the mercerizing of yarn/thread/filament, processing textile material carrier, etc., can solve the problems of unstable yarn feeding, time-consuming and laborious, complicated operation, etc., achieve time saving, precise and simple operation, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

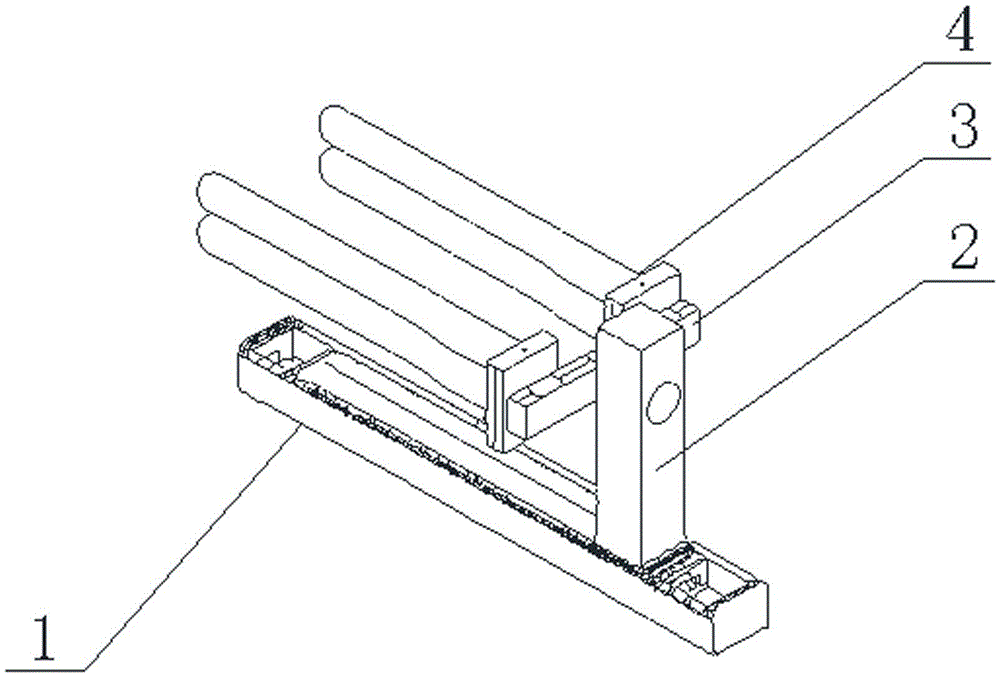

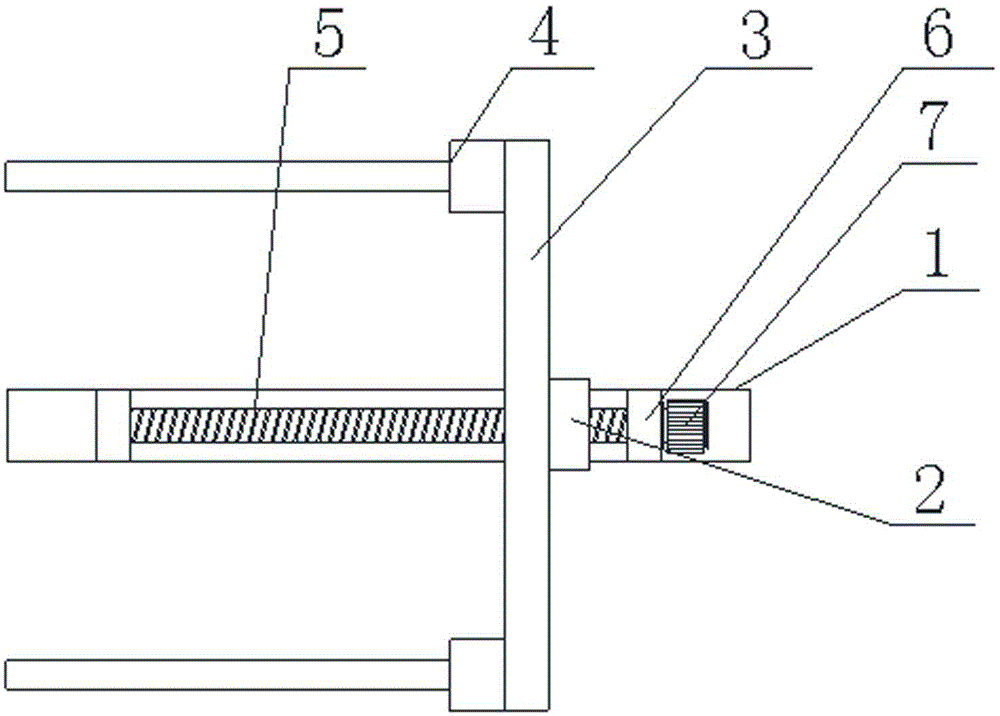

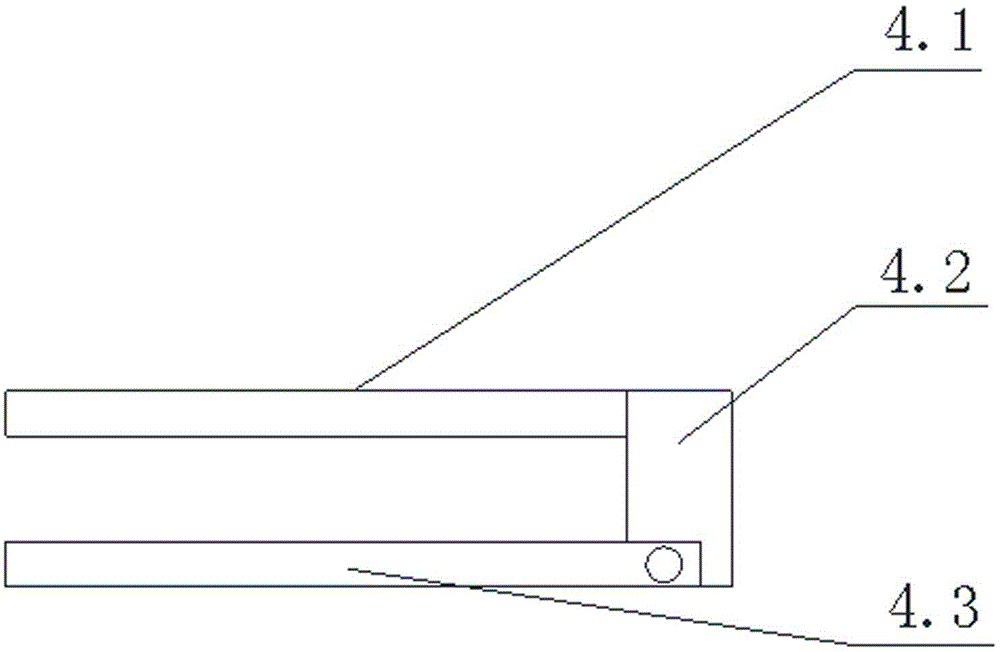

[0035] The mercerizing machine of the present embodiment uses an automatic yarn-loading device, such as Figure 1-4 As shown, it includes a chute 1, a screw 5, a column 2, a motor 7, a beam 3 and two yarn hosting devices 4; Parallel to the axis of the chute 1 , limit blocks 6 are arranged at both ends of the screw rod 5 . The lower end of the column 2 can slide along the chute 1 and is arranged in the chute 1. The lower end of the column 2 is provided with a through hole, and the screw mandrel 5 is set through the through hole. The external thread of rod 5 matches the internal thread. The motor 7 is arranged in the chute 1 close to the screw rod 5 for driving the screw rod 5. The middle part of the beam 3 is hinged with the upper end of the column 2. The axis of the beam 3 and the axis of the screw rod 5 are perpendicular to each other. Two yarn hosting devices 4 installed on both ends of the beam. The yarn hosting device 4 includes an upper yarn hosting 4.1, a lower yarn h...

Embodiment 2

[0046] This embodiment is basically the same as the first embodiment, except that the yarn hosting device 4 is arranged on the balance beam 3 so as to be slidable along the beam 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com