Linked vat dyeing method

A dyeing method and the technology of combined cylinders, applied in the field of combined cylinders dyeing, to achieve the effect of reducing energy consumption, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

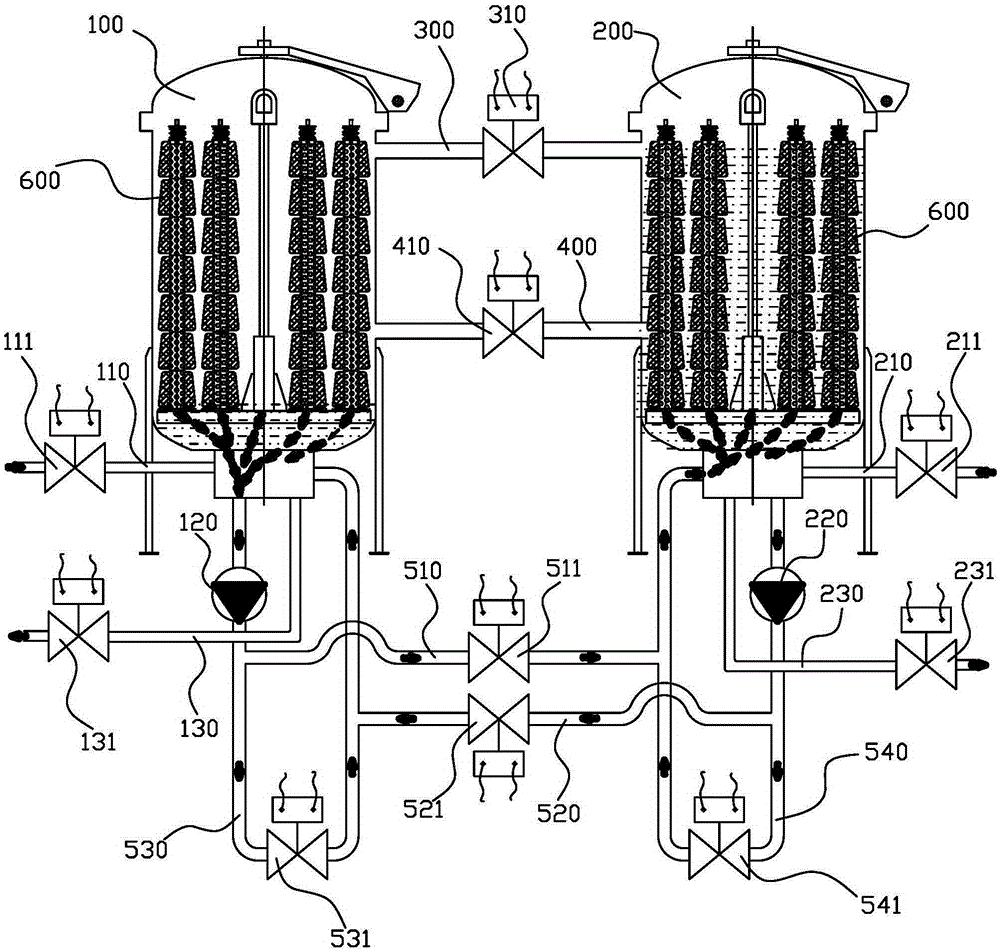

[0029] A device for dyeing with cylinders, such as figure 1 As shown, a main dye vat 100 and a slave dye vat 200 are included.

[0030] The upper part of the main dye vat 100 communicates with the upper part of the dye vat 200 through an air pressure balance pipeline 300 , and the air pressure balance pipeline 300 is provided with an air pressure balance valve 310 . The lower part of the main dyeing vat 100 communicates with the lower part of the secondary dyeing vat 200 through a liquid communication pipeline 400 , and a communication valve 410 is provided on the liquid communication pipeline 400 .

[0031] The main dye vat 100 is provided with a first water inlet pipe 110 and a first water outlet pipe 130, on which a first water inlet valve 111 and a first water outlet valve 131 are respectively arranged; the slave dye vat 200 is provided with a second water inlet pipe 210 and the second water outlet pipe 230, on which are respectively provided with the second water inlet v...

experiment example

[0047] 1. Dyeing effect.

[0048] Adopt the method for the dyeing of cylinders of embodiment 1, carry out the dyeing test of cylinders.

[0049] 1. Test plan:

[0050] The first dye solution main pump and the second dye solution main pump are both 50HZ dual-cylinder dyeing equipment. According to the method of the above-mentioned embodiment 1, when the dyeing is started, one main pump is turned on, the other main pump is turned off, and the two main pumps alternate switch, toggle every 15 seconds.

[0051] 2. Test situation:

[0052] Arrange for trial production of 1 cylinder of gray yarn, the color difference between inside and outside is comparable to that of normal bulk products, and the color dyeing is normal.

[0053] 3. Test data:

[0054] The test cylinder number is C304685780 / 2GYE0141, the package yarn specification is 0.9KG / piece, a total of 6 pieces, the computer value of the internal and external difference is tested, the computer test value and the human eye ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com