Puncher for mine

A technology for drilling machines and mines, used in rotary drilling machines, drilling equipment and methods, construction, etc., can solve problems such as inconvenience, large vibration and difficult operation, and achieve convenient operation, high safety performance, and excellent practical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

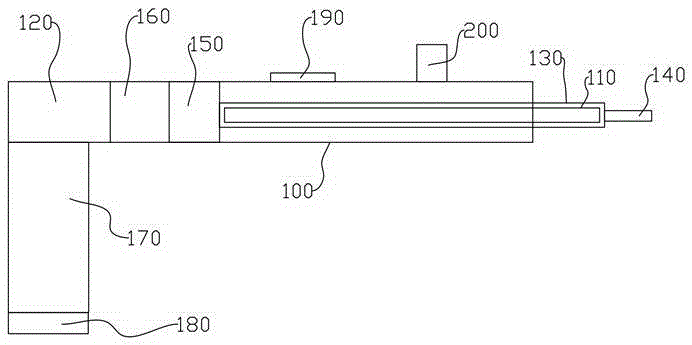

[0016] See figure 1 , One A drilling machine used in mines includes a casing 100. The inside of the casing 100 is a cavity structure. One end of the casing 100 is provided with a control handle 120, and the other end of the casing 100 is installed with a drilling shaft 110 and a drilling shaft. The surface of the 110 is provided with a protective layer 130, one end of the drilling shaft 110 is connected to the main shaft of the motor 150, the other end of the drilling shaft 110 is connected to the drill bit 140, the control handle 120 is provided with a shockproof support frame 170, and the bottom of the shockproof support frame 170 A cushion 180 is provided, a control switch 190 is installed on the surface of the casing 100, a detachable conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap