Multifunctional guardrail device

A guardrail device and multi-functional technology, which can be used in supporting devices, drilling equipment, earth-moving drilling, etc., can solve the problems of cumbersome and time-consuming disassembly and installation and fixing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

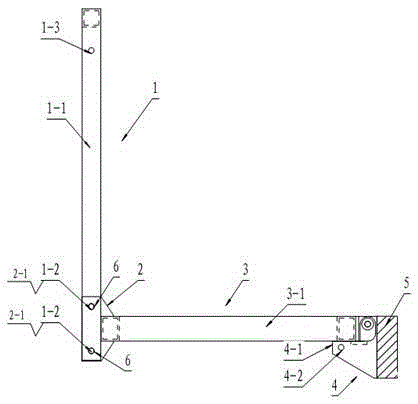

[0019] see figure 1 , The multifunctional guardrail device of the present invention includes a guardrail body 1 and a sub-platform 3, and the guardrail body and the sub-platform are foldable structures. figure 1 Shown is the use state of the multifunctional guardrail device. In this state, the auxiliary platform is unfolded horizontally, and the right end of the auxiliary platform is fixed to the main platform 5 through the support seat 4, thereby expanding the operating space of the main platform; the guardrail body is in a vertical state , The guardrail body plays a protective role.

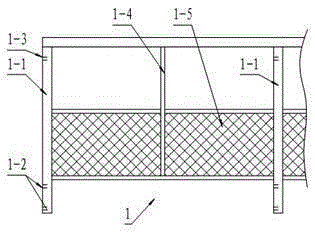

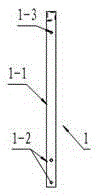

[0020] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , The guardrail body 1 is a frame structure, the guardrail body includes several guardrail frames 1-1 arranged in parallel, guardrail bars 1-4 are arranged between adjacent guardrail frames, and the guardrail body is provided with a protective net 1-5. The auxiliary platform is a frame structure, and the auxiliary platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com