Transmission main box lock stop protection mechanism

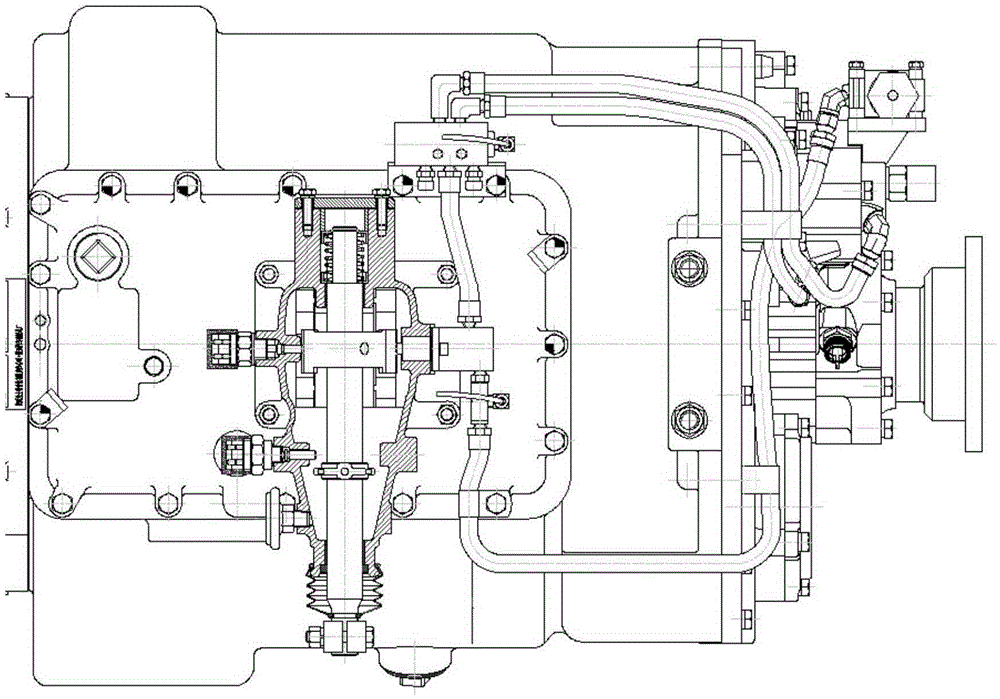

A technology for protecting mechanisms and transmissions, applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of gearbox synchronizer damage, synchronizer damage, shortened synchronizer life, etc., to achieve a small number , high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

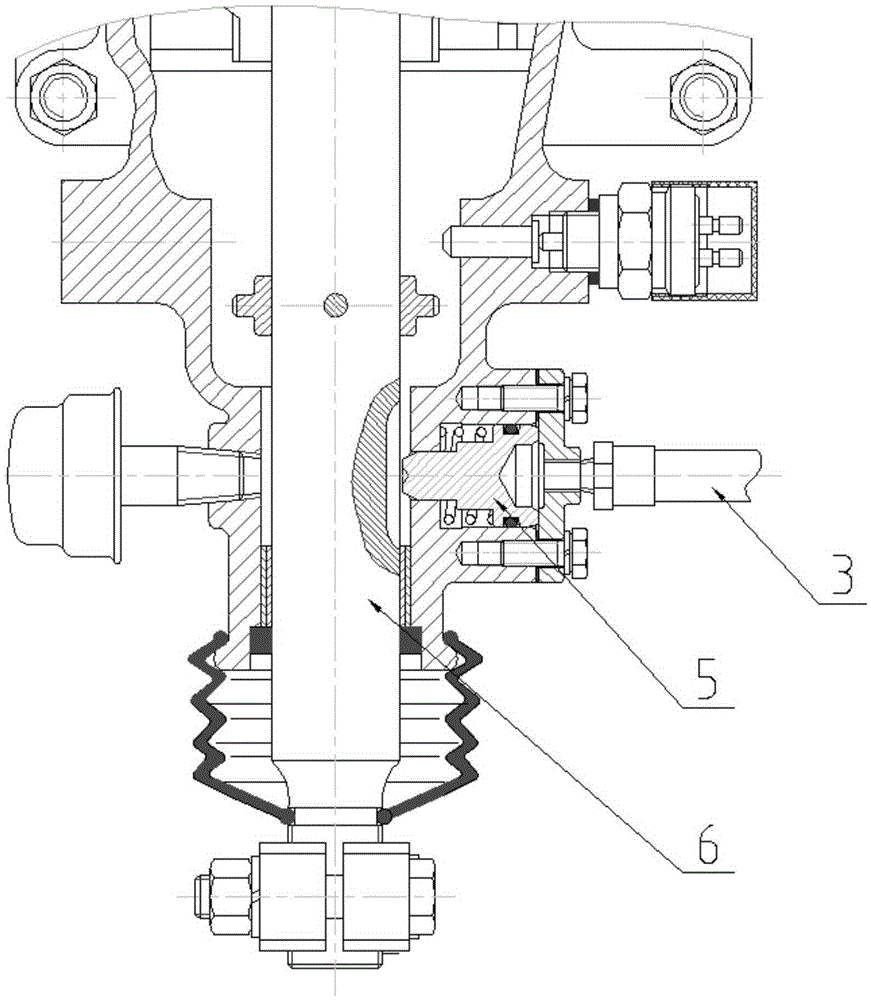

[0023] see figure 1 and figure 2 , figure 1 It is a simple diagram of the control structure of a common gearbox, figure 2 It is a partial sketch of the operating mechanism of the present invention, and the biggest difference between the two is that a cylinder-piston actuator 4 is added to the original gearbox operating device. When the air pipe 3 and the cylinder have air, the air pressure overcomes the spring force, the piston 5 stretches out, and there is a corresponding groove on the shift shaft 6, both function to limit the rotation of the shift shaft 6; when the cylinder has no air At this time, the piston rod automatically returns under the action of the spring, releasing the restriction on the shift shaft.

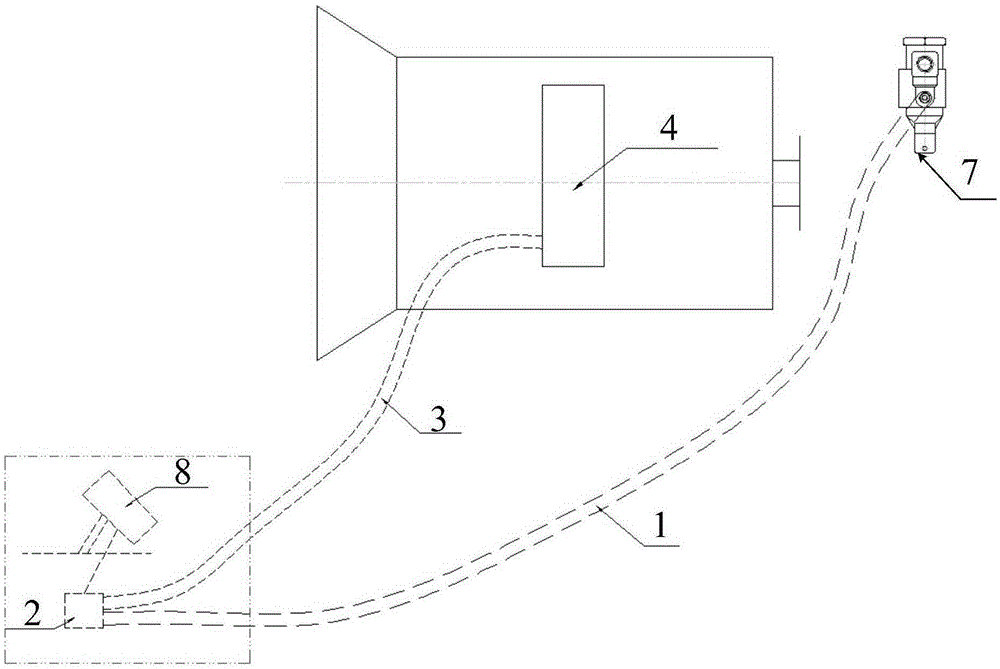

[0024] For the gas connection of the whole system, see image 3 or Figure 4 . At cab clutch pedal 8 ( image 3 ) or booster pump 9 ( Figure 4 ) add an on-off air valve 2 as the control air valve, the air source of the air valve is connected to the air fi...

Embodiment 2

[0031] Example 2 is "ventilation unlock":

[0032] Such as Figure 5 As shown, when the piston 5 has no gas in the air pipe 3, due to the promotion of the spring force, the piston 5 interacts with the shift shaft 6 grooves, the shift shaft can not rotate, and the driver can not be in gear. When trachea and cylinder had gas, piston 5 customer service spring force under gas pressure effect is backed away from shift shaft one side, removes the locking of shift shaft 6, shift shaft 6 can rotate, and the driver can shift gears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com