Automatic reversing liquid phase injection pump

A syringe pump and liquid phase technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increased liquid transmission pulsation, single function, and decreased precision of syringe piston reciprocating movement, so as to improve stability and sensitivity and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

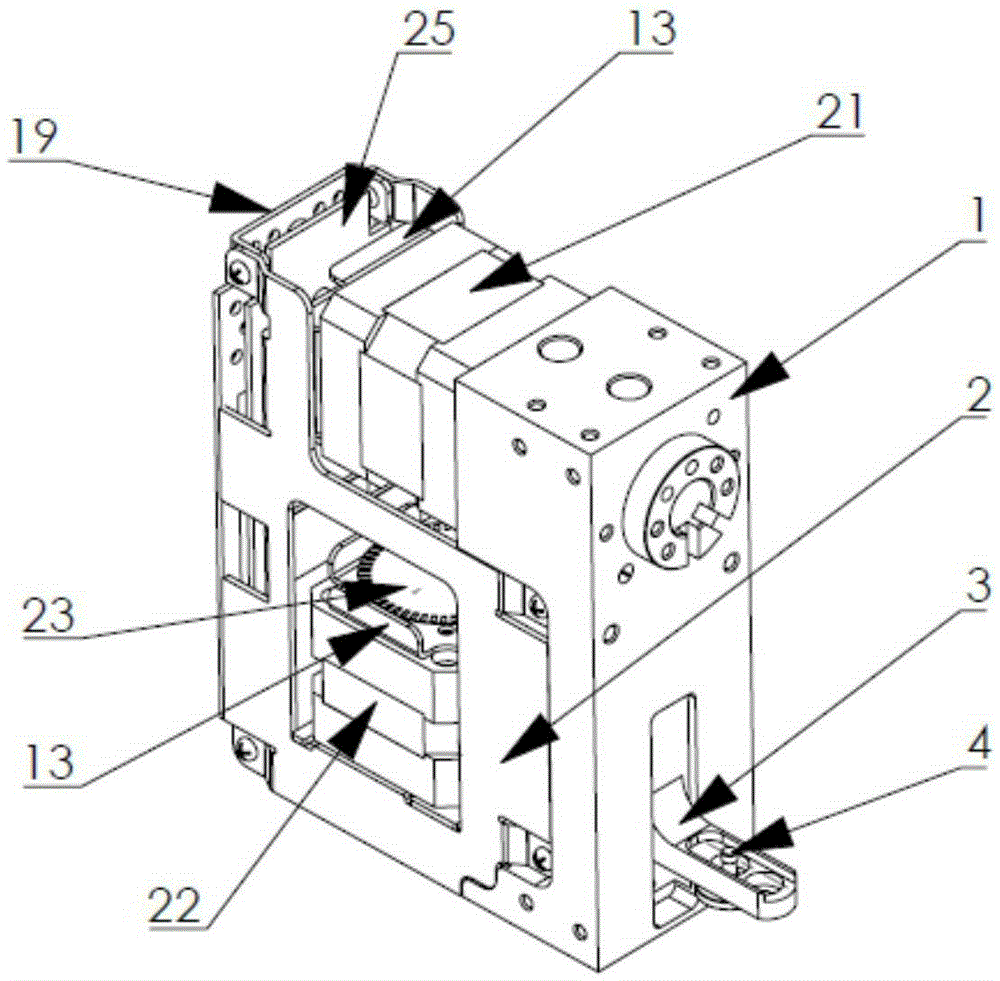

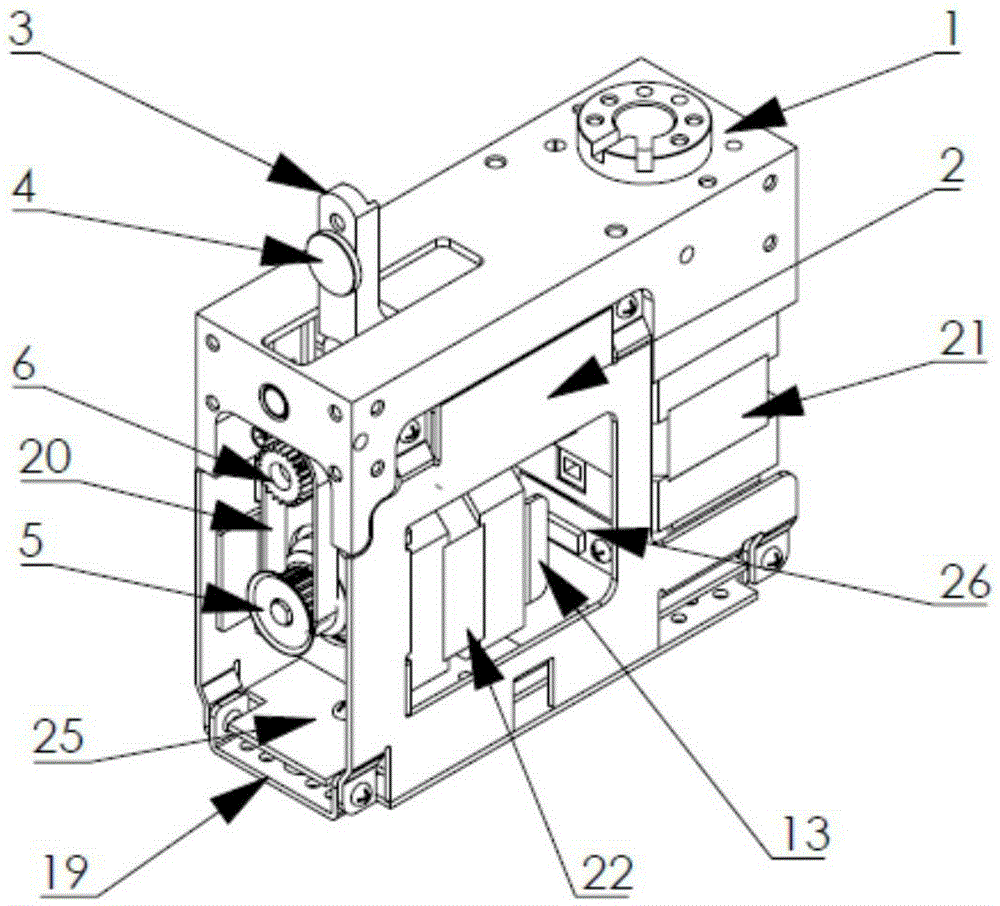

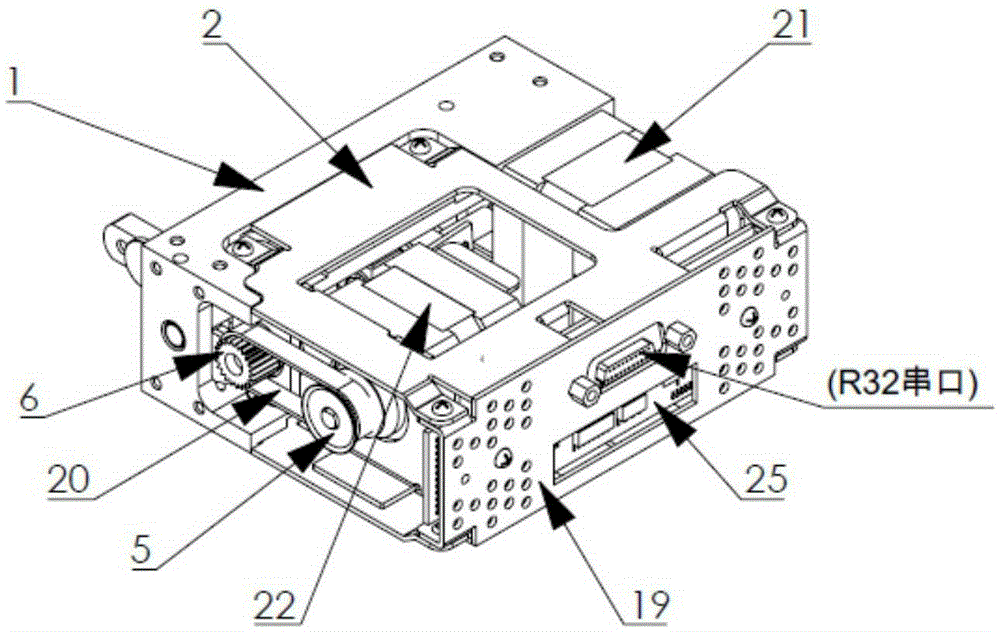

[0127] This embodiment provides an automatic reversible liquid-phase injection pump, including: a pump body, a frame, a moving seat, a reversing stepping motor, a guide shaft, a drive screw, an anti-backlash nut assembly, a linear bearing, and a syringe connection Screws, linear drive stepper motors, synchronous pulleys with guards, timing belts and synchronous pulleys without guards; of which:

[0128] The pump body is provided with peripheral mounting holes, and the peripheral mounting holes include mounting holes for installing the frame, guide shaft, and drive screw respectively, and the pump body is also provided with a reversing stepping motor The mounting surface and positioning hole for installation are provided with an inner cavity for accommodating the biaxial transmission mechanism and a long slot for the linear movement of the moving seat;

[0129] The pump body is also provided with other peripheral installation holes except for the installation holes for the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com