Double-fan control cabinet system based on air cooling technology

A control cabinet and dual fan technology, applied in the field of control cabinets, can solve problems such as heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

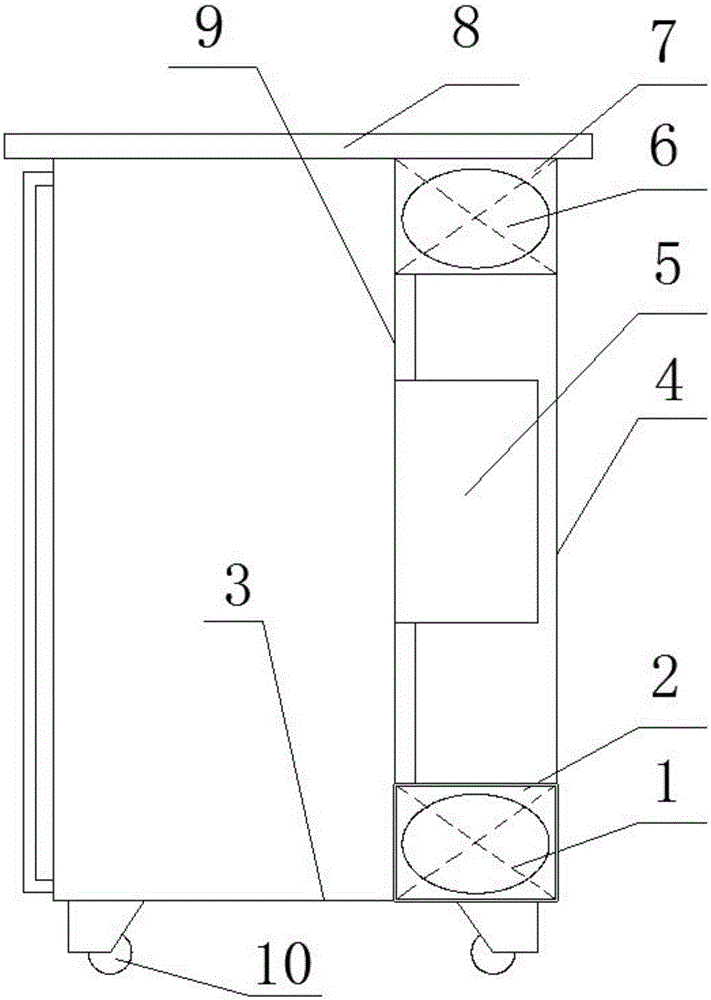

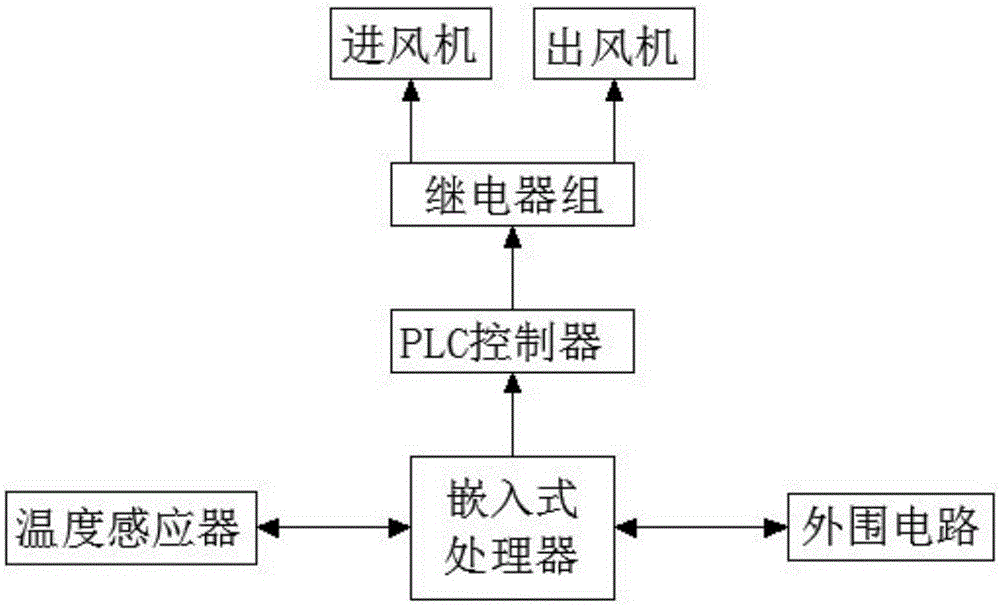

[0021] A control cabinet system with dual fans based on air-cooling technology. A control cabinet system that uses air-cooling technology to effectively dissipate the heat accumulated in the control cabinet is designed. The cold air quickly enters the control cabinet, and the hot air can also be quickly discharged from the control cabinet, so that the control cabinet can continue to work within the normal operating temperature, avoiding the occurrence of control failure; use the temperature sensor to automatically install the electrical components The temperature in the space where the electrical components on the board are located is sensed, and then the power of the inlet fan and the outlet fan is automatically adjusted according to the measured temperature results to achieve the purpose of effective energy saving, such as figure 1 , figure 2 As shown, it is specially set up as the following structure: including the control cabinet and the fan control circuit arranged on th...

Embodiment 2

[0024] This embodiment is further optimized on the basis of the above-mentioned embodiments. In order to better realize the present invention, the two independent spaces in the control cabinet will not affect each other, and the air duct space where the air inlet is located may Incoming dust will not be brought into the space where the front panel of the electrical component installation board is located, affecting the operation of electrical components, such as figure 1 , figure 2 As shown, the following structure is particularly arranged: the four sides of the electrical component mounting plate 9 are respectively sealed and fixedly connected with the inner surfaces of the control cabinet top plate 8, the control cabinet bottom plate 3, the left panel of the control cabinet and the right panel 4 of the control cabinet.

Embodiment 3

[0026] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, it can accelerate the heat release from the space where the front panel of the electrical component installation board is located to the air duct space where the rear panel of the electrical component installation board is located. inside, and then release the heat from the air duct space, such as figure 1 As shown, the following structure is particularly provided: the radiator 5 is an aluminum alloy strip, and an exhaust fan is also arranged on the aluminum alloy strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com