Magnesium metal smashing and grading device and technique thereof

A crushing and grading and crushing device technology, which is applied in the field of metal magnesium crushing and grading devices, can solve the problems of large liquid nitrogen consumption, inability to classify and separate materials, and single function, and achieve the effects of saving resources, protecting safety, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

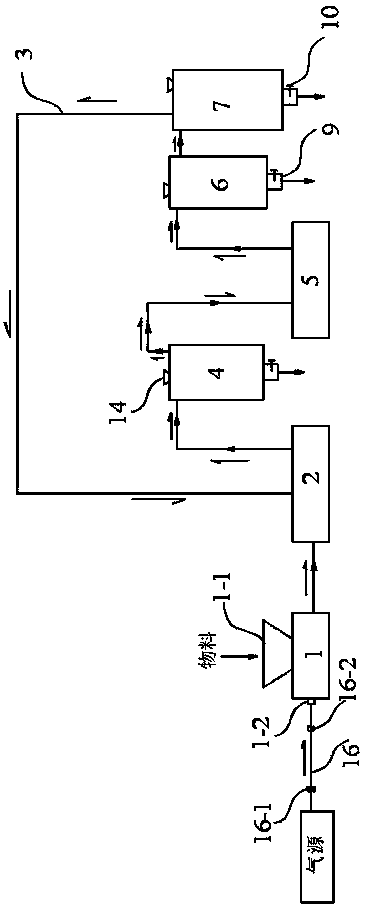

Embodiment 1

[0033] refer to figure 1, the present invention provides a metal magnesium crushing and grading device, including a feeding device 1, a crushing device 2, an inert gas circulation loop, a primary gas-solid separation device 4, a wind drive device 5, a secondary gas-solid separation device 6 and a dust collector Device 7, feeding device 1, crushing device 2, primary gas-solid separation device 4, wind drive device 5, secondary gas-solid separation device 6 and dust collection device 7 are connected in sequence, and feeding device 1 is provided with material inlet 1-1 and The inert gas inlet 1-2, the dust collection device 7 is provided with an inert gas outlet, and the inert gas circulation loop sends the inert gas separated from the dust collection device 7 to the crushing device 2 through the air return pipe 3, and the inert gas is recycled, and the first-level gas-solid The upper parts of the separation device 4 , the secondary gas-solid separation device 6 and the dust coll...

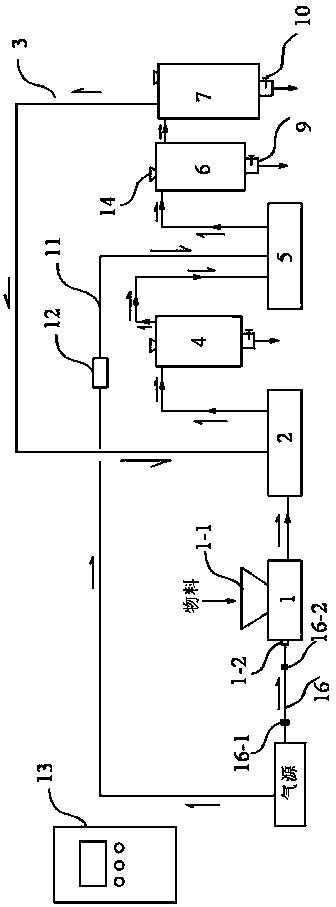

Embodiment 2

[0045] refer to figure 2 , the present invention provides a metal magnesium crushing and grading device, including a feeding device 1, a crushing device 2, an inert gas circulation loop, a primary gas-solid separation device 4, a wind drive device 5, a secondary gas-solid separation device 6 and a dust collector Device 7, feeding device 1, crushing device 2, primary gas-solid separation device 4, wind drive device 5, secondary gas-solid separation device 6 and dust collection device 7 are connected in sequence, and feeding device 1 is provided with material inlet 1-1 and The inert gas inlet 1-2, the dust collection device 7 is provided with an inert gas outlet, and the inert gas circulation loop sends the inert gas separated from the dust collection device 7 to the crushing device 2 through the air return pipe 3, and the inert gas is recycled, and the first-level gas-solid The upper parts of the separation device 4 , the secondary gas-solid separation device 6 and the dust co...

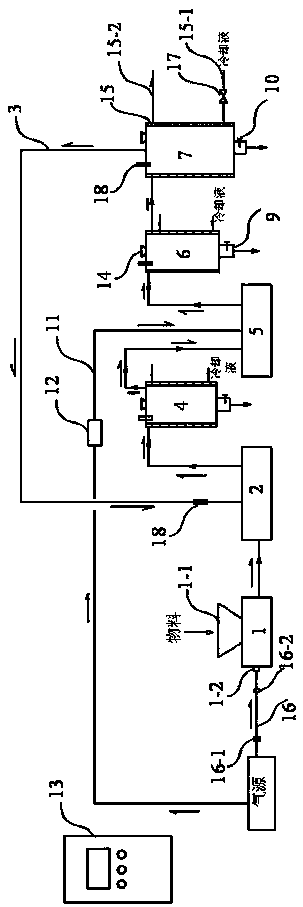

Embodiment 3

[0055] refer to image 3 , the present invention provides a metal magnesium crushing and grading device, including a feeding device 1, a crushing device 2, an inert gas circulation loop, a primary gas-solid separation device 4, a wind drive device 5, a secondary gas-solid separation device 6 and a dust collector Device 7, feeding device 1, crushing device 2, primary gas-solid separation device 4, wind drive device 5, secondary gas-solid separation device 6 and dust collection device 7 are connected in sequence, and feeding device 1 is provided with material inlet 1-1 and The inert gas inlet 1-2, the dust collection device 7 is provided with an inert gas outlet, and the inert gas circulation loop sends the inert gas separated from the dust collection device 7 to the crushing device 2 through the air return pipe 3, and the inert gas is recycled, and the first-level gas-solid The upper parts of the separation device 4 , the secondary gas-solid separation device 6 and the dust col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com