Grain winnowing device with floating shedding plate

A kind of floating, flowing plate technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve problems such as high cost, complex structure, adjustment, etc., to achieve strong practicability, structure simple effect

Inactive Publication Date: 2016-03-02

CHONGQING LONGYUE FOOD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problems that exist in the above-mentioned vertical suction winnowing device are: 1. The adjustment of the air volume entering the winnowing channel is realized by an additional regulating valve (such as a butterfly valve), which has a complex structure and high cost; 2. The inclination of the dripping plate The angle cannot be adjusted, and it is impossible to adjust the amount of material entering the wind separation channel according to the wind separation requirements of different materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

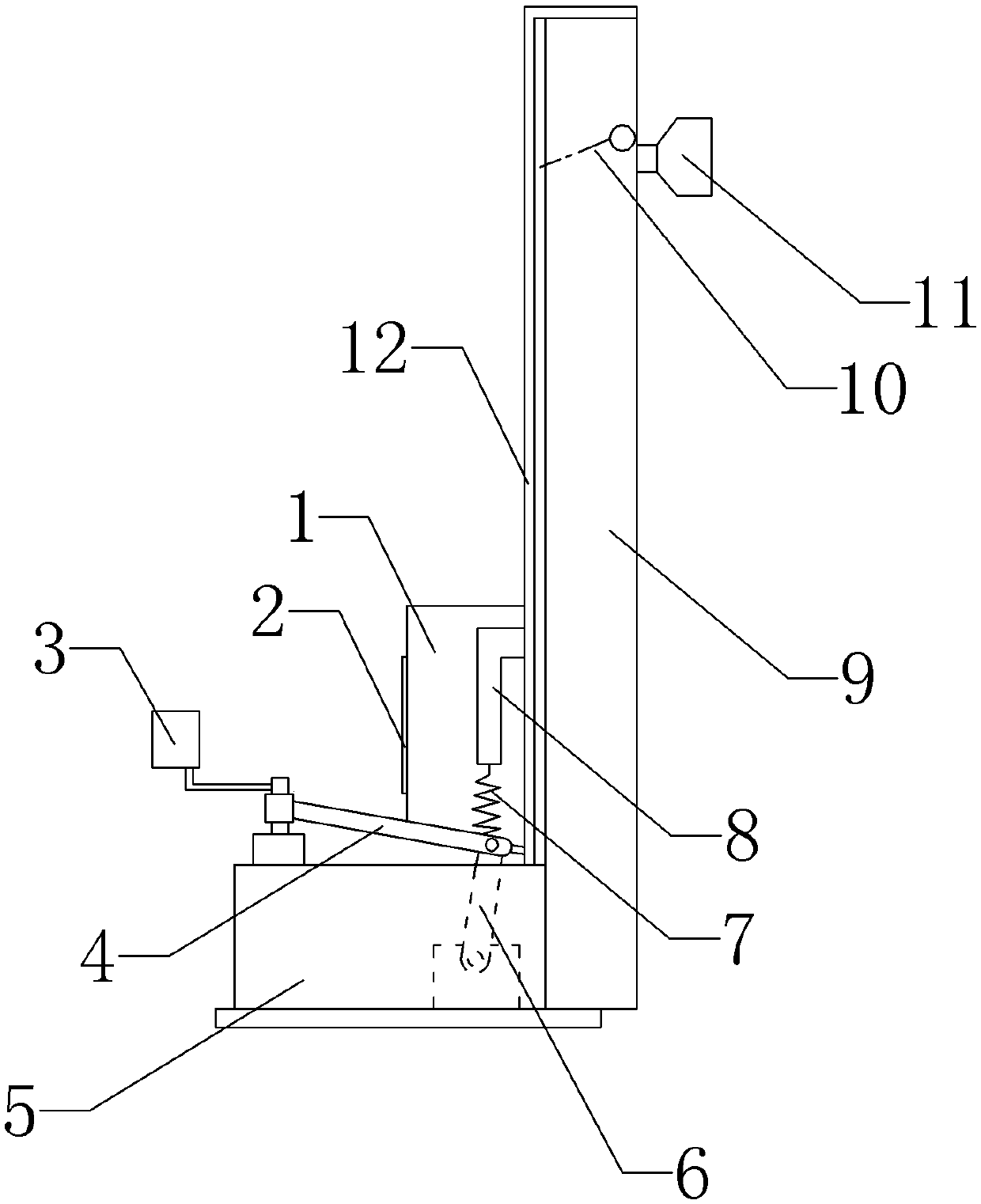

The invention discloses a grain winnowing device with a floating shedding plate. The grain winnowing device with the floating shedding plate comprises a feed cylinder, and the shedding plate and an air-intake box which are positioned below the feed cylinder in sequence, a winnowing box is arranged in the side direction of the feed cylinder, the air-intake box is communicated with the winnowing box, a feed port is formed in a side wall of the winnowing box, the end part of the shedding plate is opposite to the feed port, the grain winnowing device is characterized in that a mounting seat is arranged inside the air-intake box, the upper part of the mounting seat is hinged to an air-intake adjusting plate, the air-intake adjusting plate is positioned at the communicating part of the air-intake box and the winnowing box, an air-intake hole is formed in the air-intake adjusting plate, the upper end of the air-intake adjusting plate is hinged to a rotating shaft, one side, close to the winnowing box, of the shedding plate is hinged to the rotating shaft, the upper part of the side, close to the winnowing box, of the shedding plate is fixed together with the lower end of a tension spring, the upper end of the tension spring is fixed on a mounting rod, the mounting rod comprises a vertical rod and a cross rod, a mounting plate is arranged in the lateral direction of the winnowing box, a strip-type groove is formed in the mounting plate, a plurality of clamping grooves are formed in the side wall of the strip-type groove, and the cross rod is positioned in the strip-type groove and can be clamped in the clamping grooves.

Description

technical field The invention relates to a grain air separation technology, in particular to a grain air separation device with a floating drip plate. Background technique According to the difference in the aerodynamic properties of grain and impurities, the method of separating by air flow is called winnowing. Wind separation equipment used for grain cleaning is divided into external suction type and circulation type according to the treatment method of dusty air, blowing type and suction type according to gas pressure, and vertical type and horizontal type according to the direction of airflow movement. There is an existing vertical suction air separation device, its main structure includes a feeding cylinder, an inclined dripping plate located below the feeding barrel, a motor that drives the vibration of the dripping plate, and an air separation channel located on the side of the feeding hopper. When working, The vibrating motor drives the dripping plate to vibrate in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B07B7/00B07B11/02

CPCB07B7/00B07B11/02

Inventor 刘行

Owner CHONGQING LONGYUE FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com