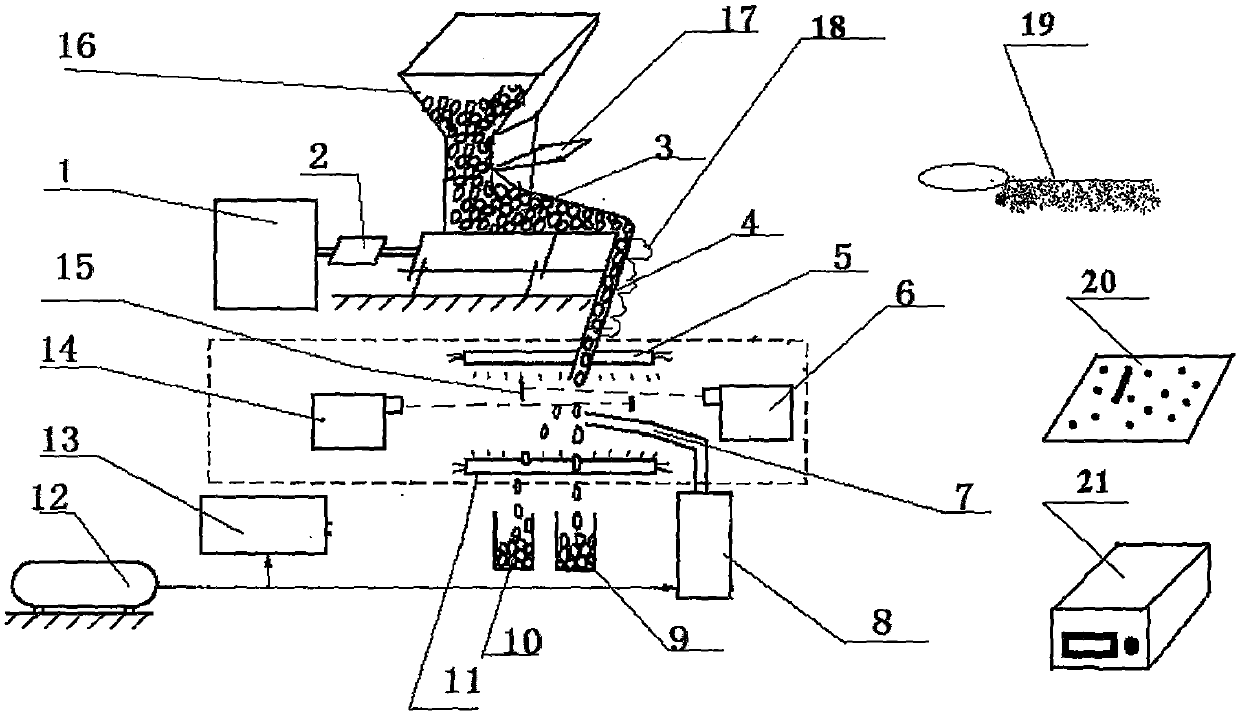

Optical-mechanical-electrical integrated device for removing impurities in rice

An opto-mechanical and rice technology, applied in chemical instruments and methods, cleaning methods using tools, cleaning methods and utensils, etc., can solve the problems of difficult continuous production, unsanitary rice, waste of manpower, etc., and achieves strong applicability, Perfect function, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Such as figure 1 As shown, add the rice that needs to be removed into the rice hopper 16, adjust the rice hopper switch 17 to make the rice 3 flow down at a moderate speed, and then turn on the oscillator switch 2 next to the oscillator 1, so that the rice 3 flows along the chute. Passage 4 slides down slowly. When the rice 3 is relatively wet, the rice will form lumps in the chute passage 4, thereby affecting the rice to slide down along the chute passage 4. At this time, the heating wire 18 will be turned on to feed the The rice is heated to prevent the rice from agglomerating due to moisture. When the rice 3 falls through the matt dark box area, the background board 15 is provided with 2 pieces, which are respectively placed in front of the left side CCD camera 14 and the right side CCD camera 6, and the background board 15, the left side CCD camera 14 and the right side CCD camera 6 Store in a sealed matte dark box. The background plate provides a reference signal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com