A horn diaphragm injection mold

A technology of injection mold and vibrating membrane, applied in coating and other directions, can solve the problems of affecting the sound quality and appearance of speakers, waste time, difficult to repair, etc., achieve lasting good sound quality, uniform thickness of silicone, and improve the effect of overflowing glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention is further described in conjunction with the following examples.

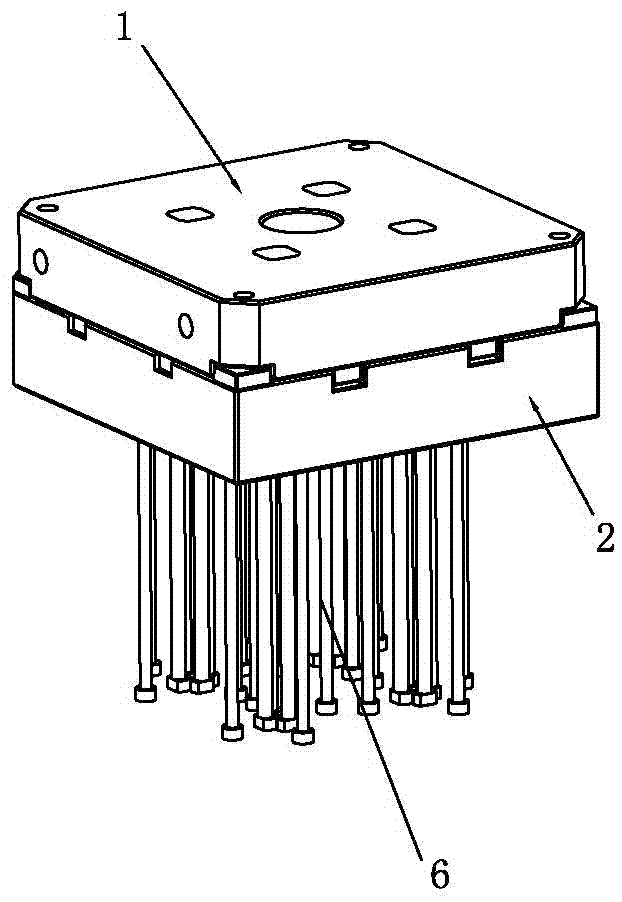

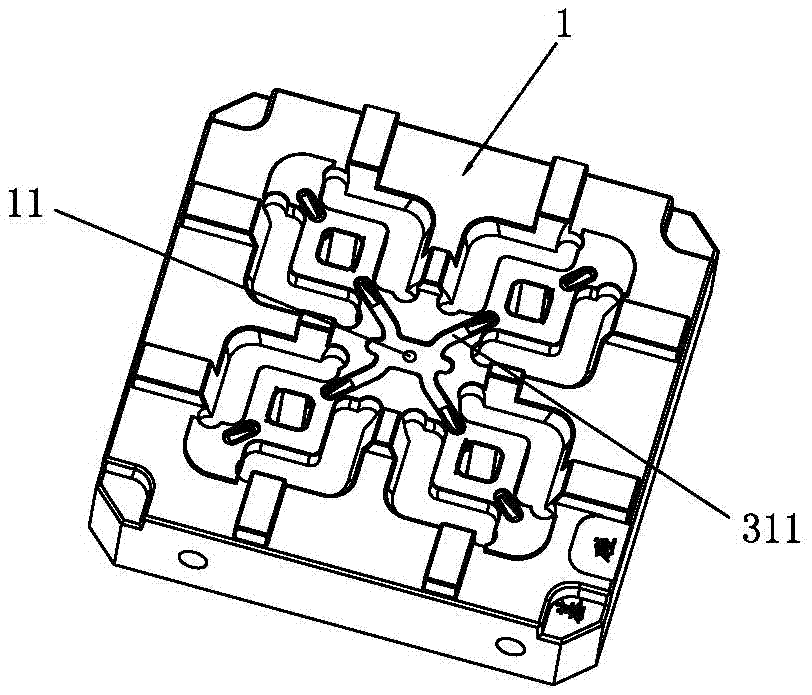

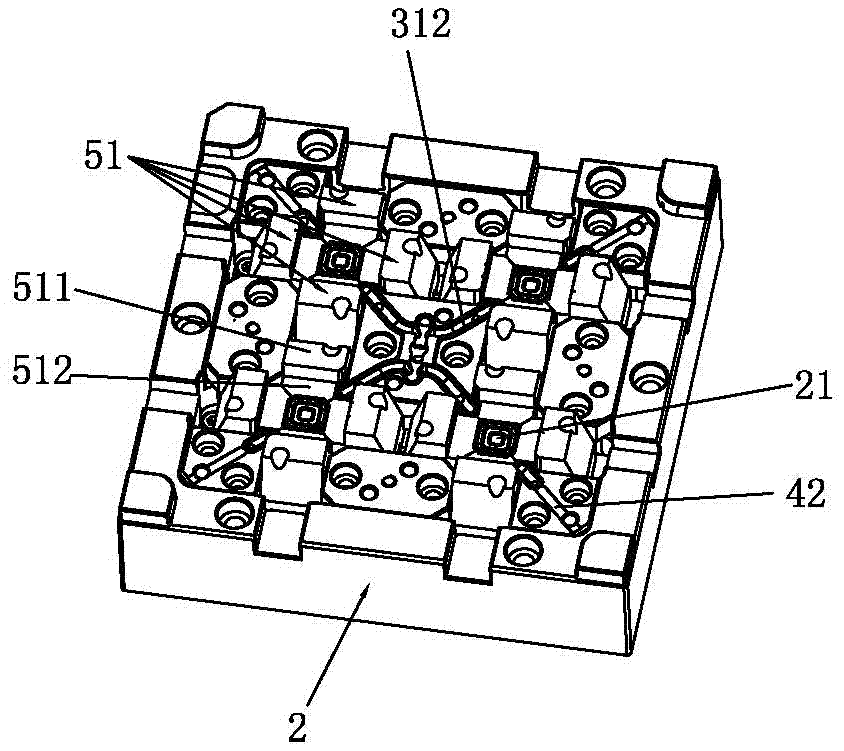

[0040] like Figure 1-3 As shown, a kind of speaker diaphragm injection mold of the present embodiment comprises a front mold 1 and a rear mold 2 used in conjunction with the front mold 1, the front mold 1 is provided with a gate 11, and the rear mold 2 is provided with a Forming the mold core 21 of the liquid silicone layer 82, the front mold 1 is provided with an insert at the position facing the mold core 21, and when the mold is closed, the insert abuts against the mold core 21; the front mold 1 and the mold core 21 A glue inlet flow channel 3 and a glue outlet flow channel 4 for liquid silica gel to flow are arranged between the back mold 2, and the glue inlet flow channel 3 includes a main glue inlet flow channel 31 and an inclined surface glue inlet flow channel 32 that communicate with each other. The glue outlet flow channel 4 includes an inclined surface glue outlet flow channel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com