Self-melting filling type steel plastic composite pipe end sealing machine and sealing method thereof

A steel-plastic composite pipe and filling technology, which is applied to the self-melting filling type steel-plastic composite pipe end sealing machine and its sealing field, can solve the problems of affecting pipe connection and use effect, sealing failure, lack of heating and cooling, etc. , to achieve the effect of guaranteed connection and use effect, overall simplicity and uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

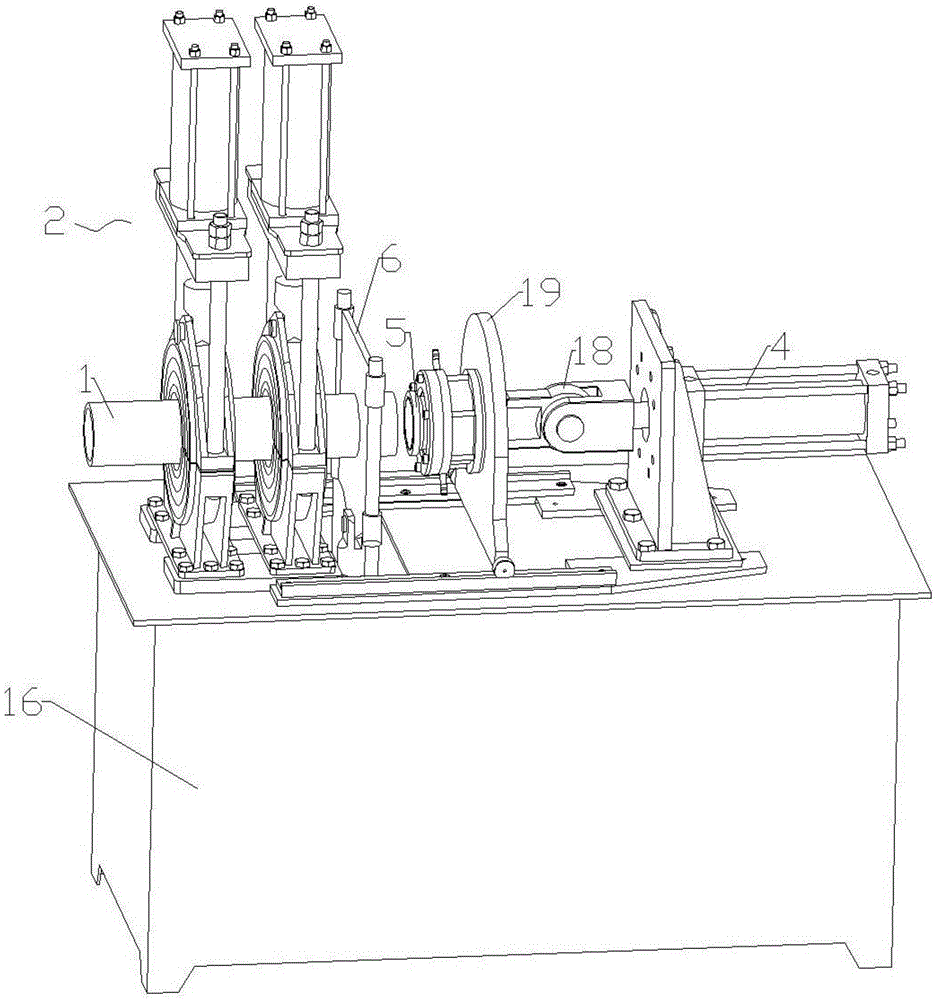

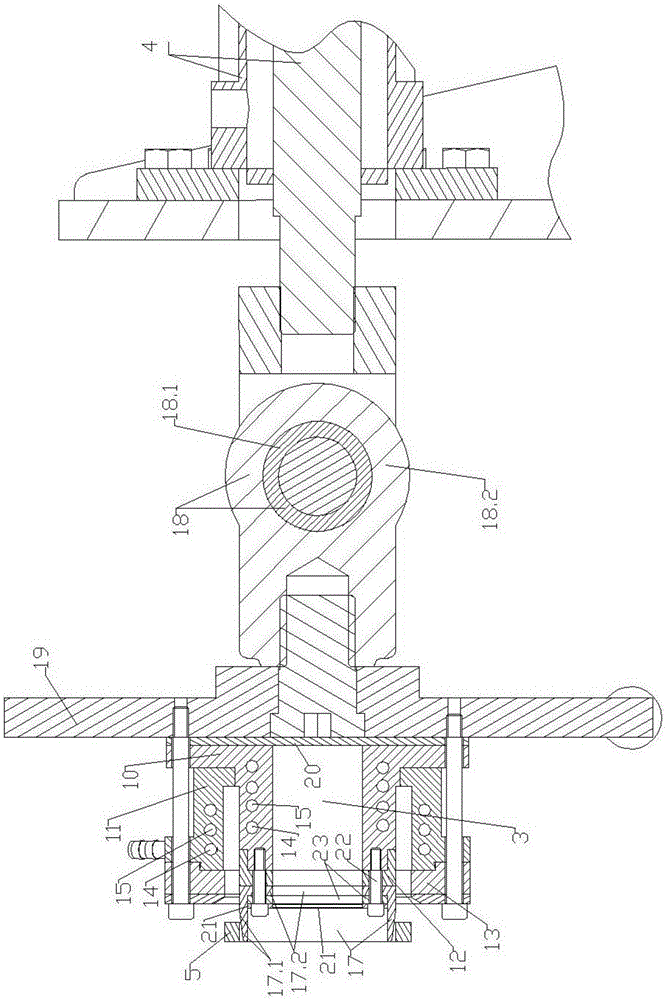

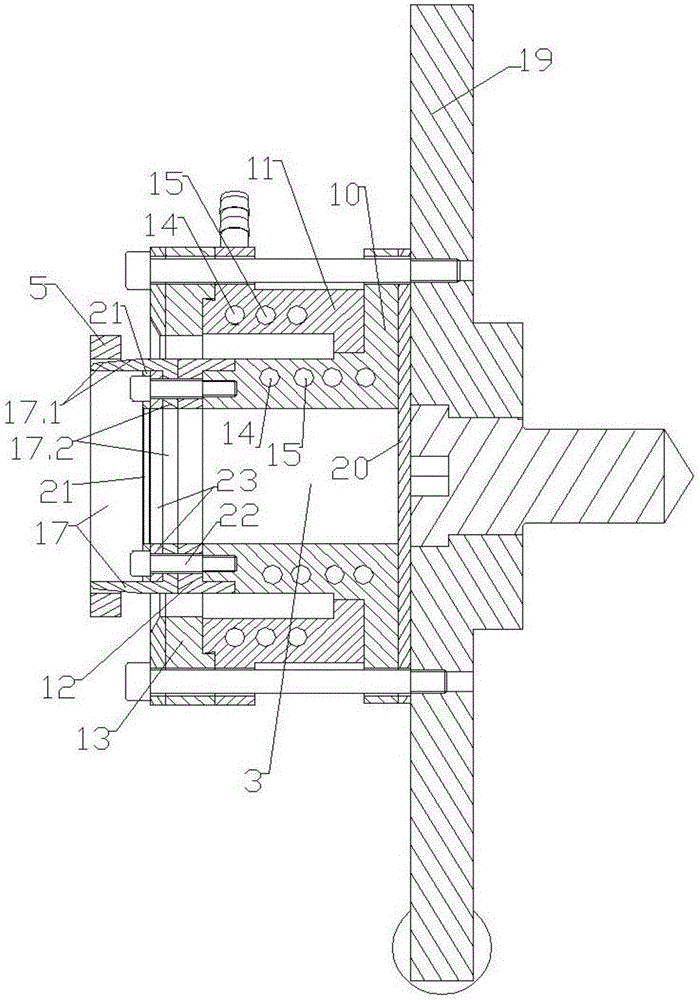

[0030]As shown in the figure, a self-melting filling type steel-plastic composite pipe end sealing machine of the present invention includes a clamping mechanism 2 for clamping the steel-plastic composite pipe 1, and then heats and seals the steel-plastic composite pipe 1. The integrated heating and cooling sealing mechanism that can cool the sealed pipe end drives the integrated heating and cooling sealing mechanism to move to the pipe end so that the pipe end can be inserted into the pipe end sealing cavity 3 of the integrated heating and cooling sealing mechanism An oil cylinder 4 or a first air cylinder, a pipe sealing ring 5 for heating and sealing the pipe ends is preset in the pipe end sealing cavity 3 . In this embodiment, the first oil cylinder 4 is the driving part that drives the integrated heating and cooling sealing mechanism to move to the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com