Automatic coating delivery and recovery device

A recycling device and coating technology, applied in the direction of inking device, rotary printing machine, printing, etc., can solve the problems that affect the printing effect of thermal paste performance, reduce the consistency of product production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

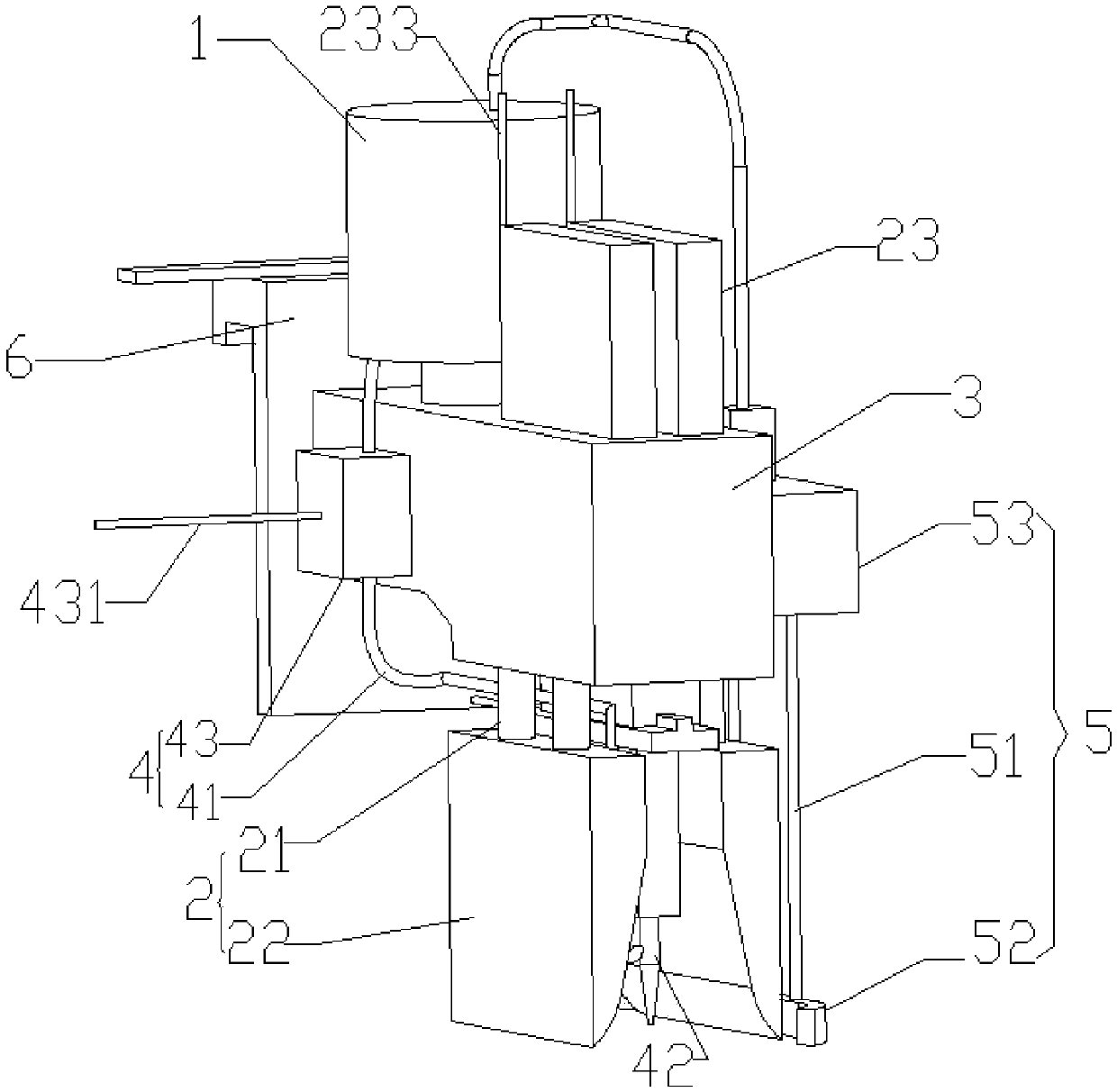

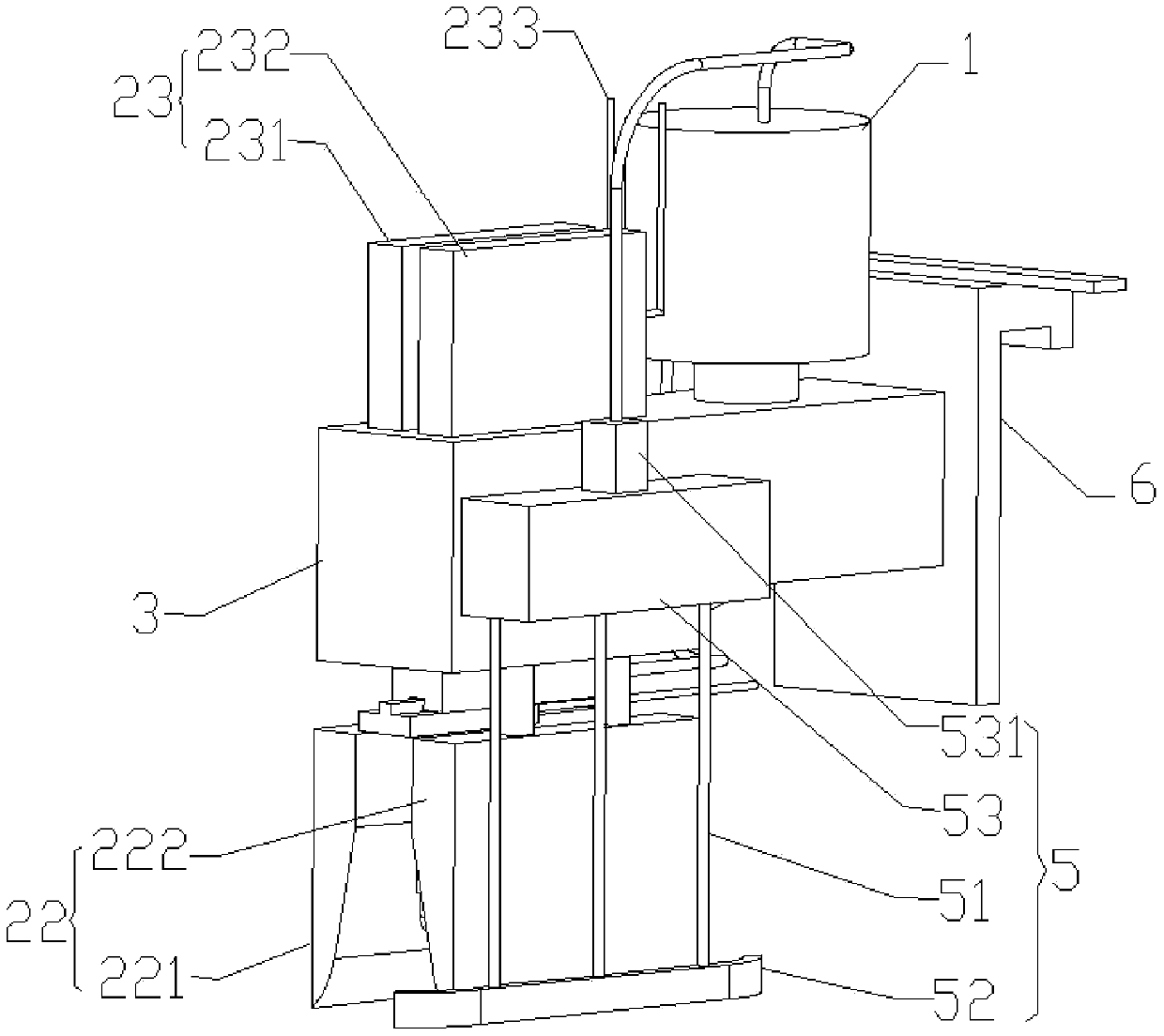

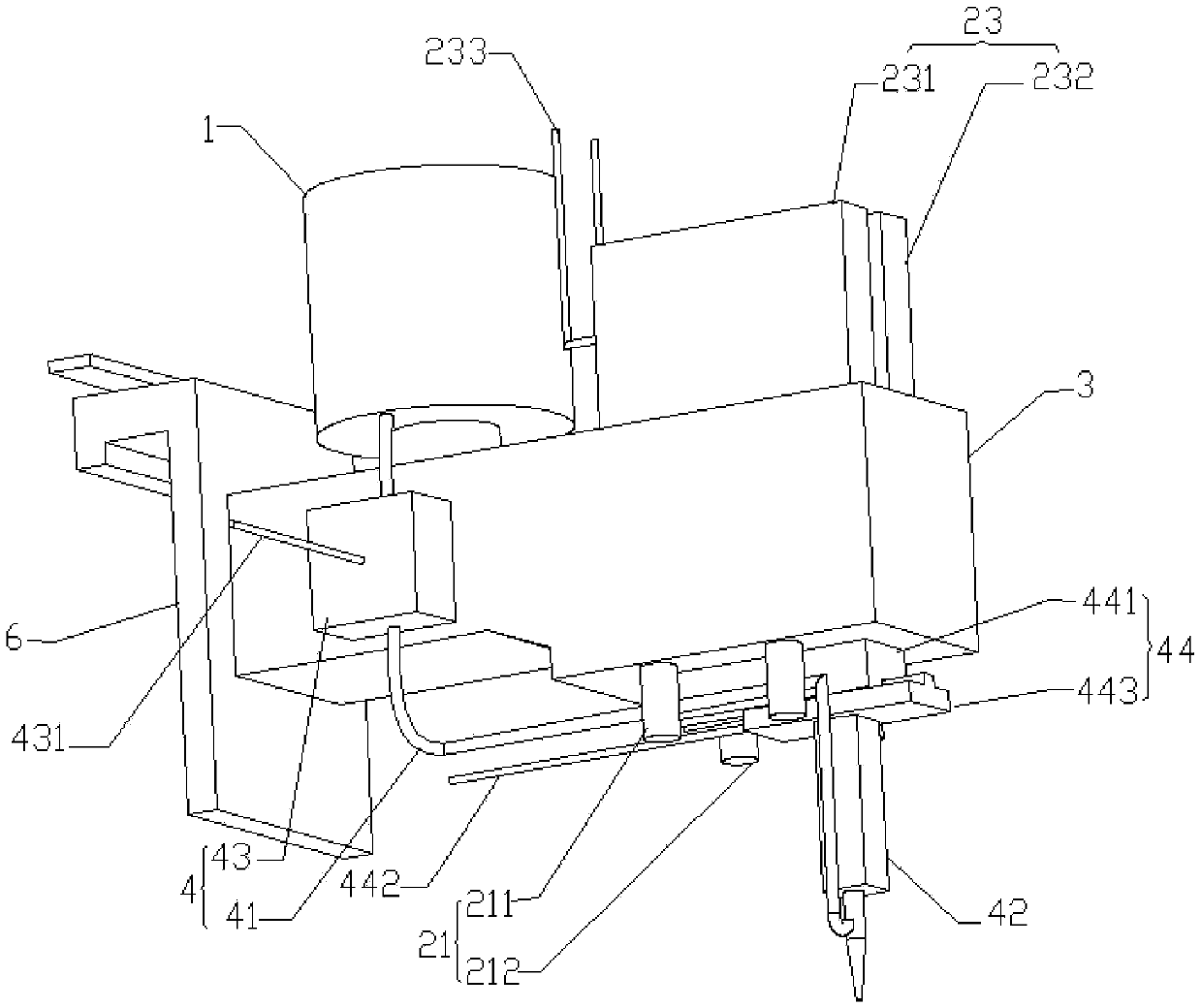

[0018] according to Figure 1 to Figure 3 Shown: an automatic paint delivery and recovery device, including: a storage tank 1, a scraping assembly 2, and a support body 3, the storage tank 1 and the scraping assembly 2 are installed on the support body 3;

[0019] Wherein, the two sides of the support body 3 are respectively provided with a delivery assembly 4 and a recovery assembly 5, so that after the paint in the storage tank 1 is delivered by the delivery assembly 4, the recovery assembly 5 is used to dispose of the paint. The remaining paint sent out is automatically recovered into the storage tank 1 to prevent the paint from being exposed to the air for a long time, thereby affecting the consistency of module printing.

[0020] The scraping assembly 2 includes a guide post 21, a scraper 22, and a cylinder 23. One end of the guide post 21 is fixed on the scraper 22, and the other end extends into the support body 3. The piston rod in the cylinder 23 extends Into the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com