Electric automobile energy-saving air-conditioner based on semiconductor refrigeration and control method thereof

A technology for energy-saving air conditioners and electric vehicles, applied in vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problems of complicated structure changes, increased power consumption, and large impact on vehicle power grids, to improve simplicity, reduce Effect of power load and energy saving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

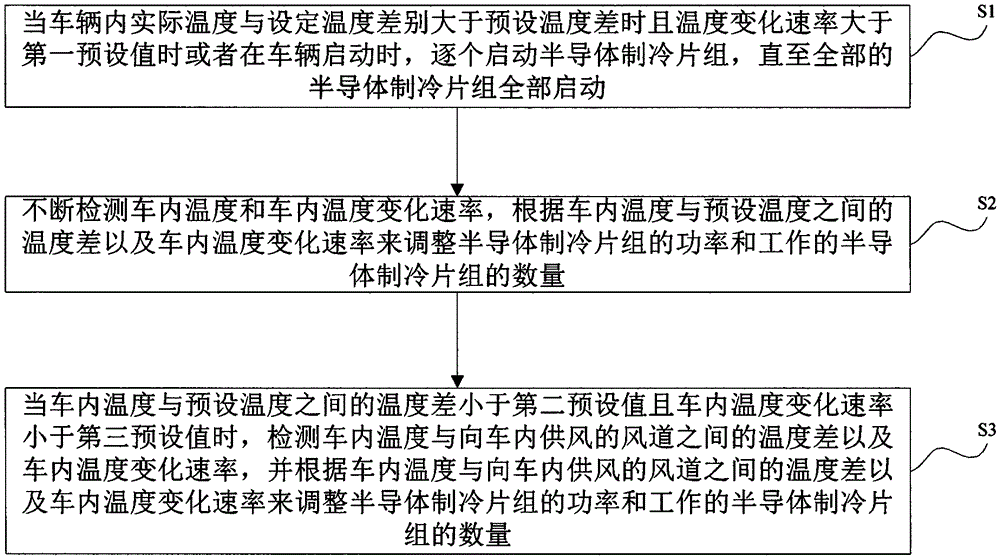

[0046] Such as figure 1 As shown, a control method of an energy-saving air conditioner for electric vehicles based on semiconductor refrigeration, wherein the energy-saving air conditioner for electric vehicles is provided with a plurality of semiconductor refrigeration sheet groups; the method is:

[0047] S1: When the difference between the actual temperature in the vehicle and the set temperature is greater than the preset temperature difference, such as 3°C, 5°C, and the temperature change rate is greater than the first preset value, or when the vehicle is started, start the semiconductor cooling chip groups one by one until all All the semiconductor refrigeration chip groups are started, and the time interval between each two semiconductor cooling chip groups is 1-5s.

[0048] Preferably, the time interval between the start-up of every two peltier cooler groups is 3-5s.

[0049] In this embodiment, the temperature inside and outside the car is detected in advance. If the...

Embodiment 2

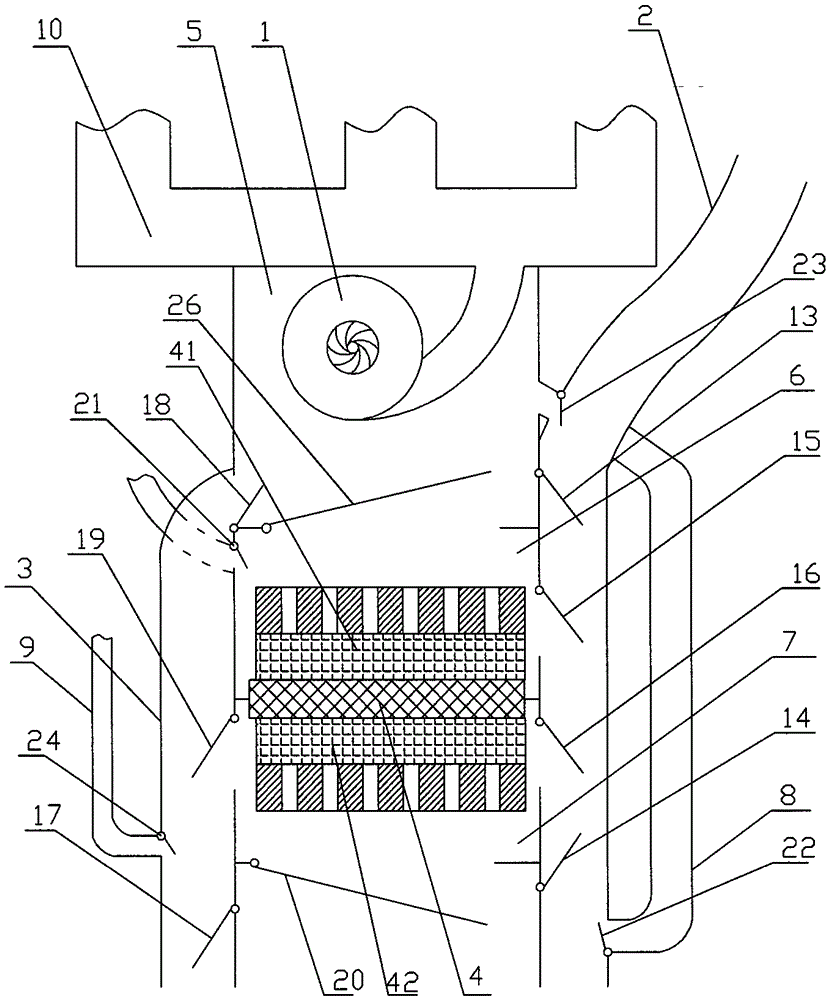

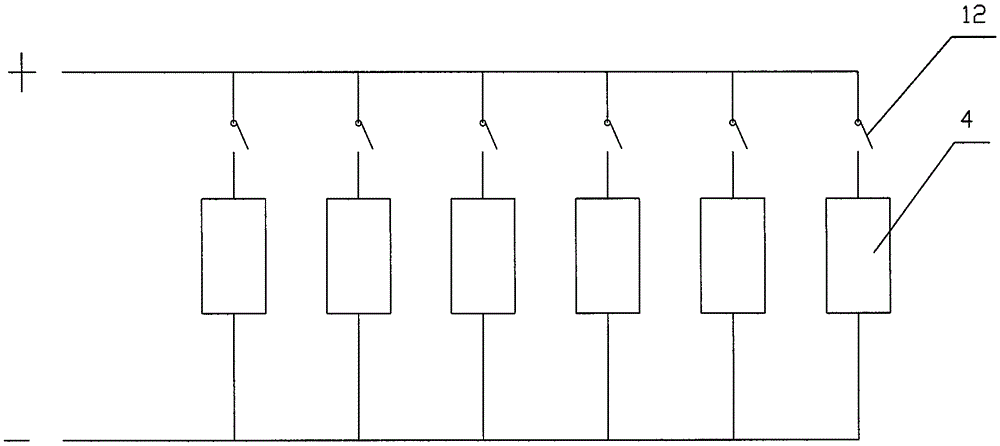

[0112] Such as Figures 2 to 4 As shown, this embodiment provides an energy-saving air conditioner for electric vehicles based on semiconductor refrigeration suitable for Embodiment 1, including a fan 1, a first air duct 2, a second air duct 3, and multiple sets of semiconductor refrigeration sheet groups 4 provided with radiators And the main air chamber 5, the cold air chamber 6, and the hot air chamber 7 connected in sequence, the fan 1 is arranged in the main air chamber 5 and the air outlet of the fan 1 communicates with the inside of the car, the cooling of the semiconductor refrigeration sheet group 4 The end 41 is arranged in the cold air chamber 6, the hot end 42 of the semiconductor refrigerating sheet group 4 is arranged in the hot air chamber 7, one end of the first air duct 2 communicates with the interior of the vehicle and the other end communicates with the exterior of the vehicle, One end of the second air duct 3 communicates with the outside of the vehicle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com