Mooring anchor leg replacement method

A replacement method, mooring anchor technology, applied in the direction of anchor arrangement, ship parts, transportation and packaging, etc., can solve the problems of huge workload and loss of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

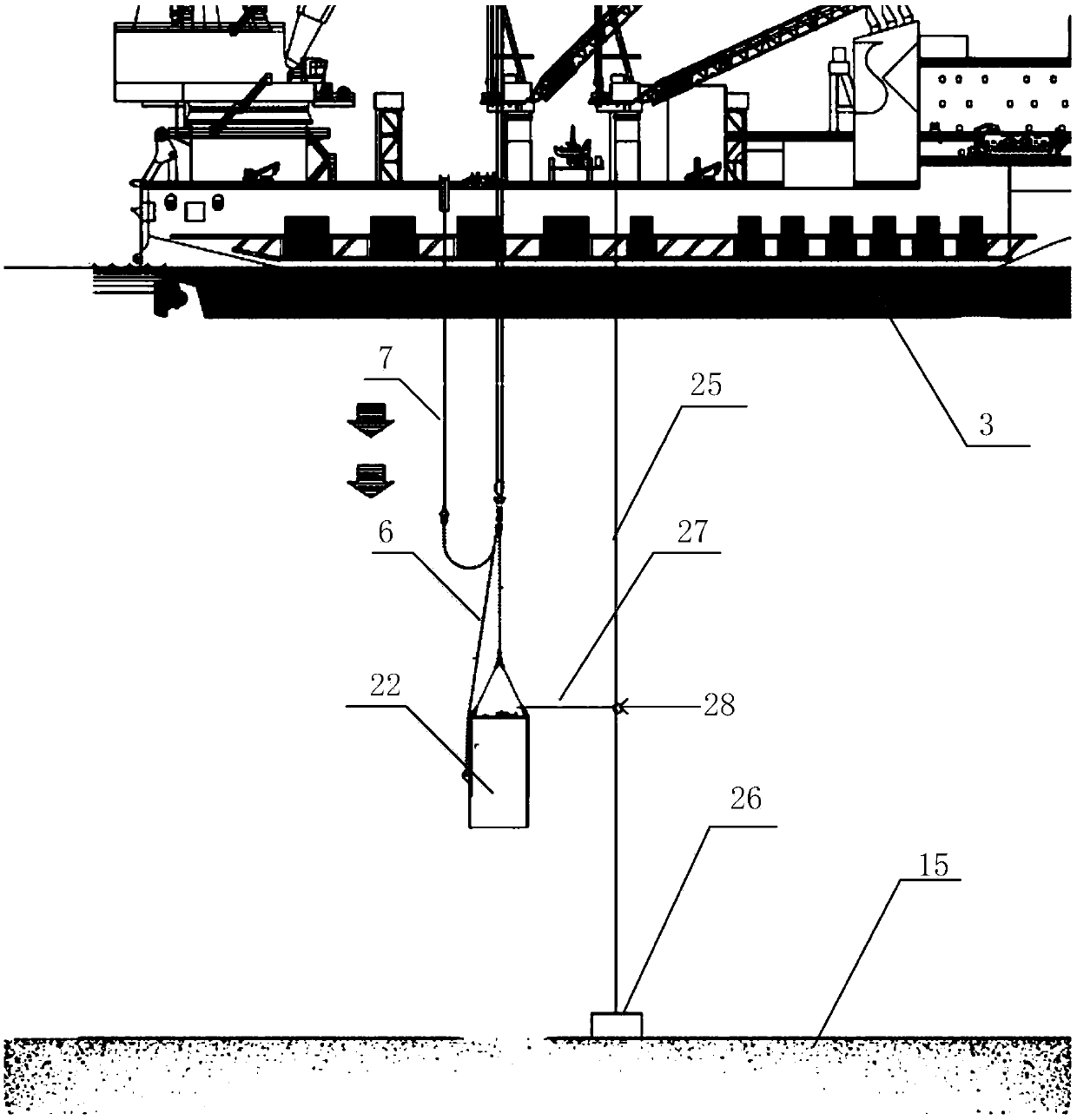

[0062] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0063] The invention provides a method for replacing mooring anchor legs.

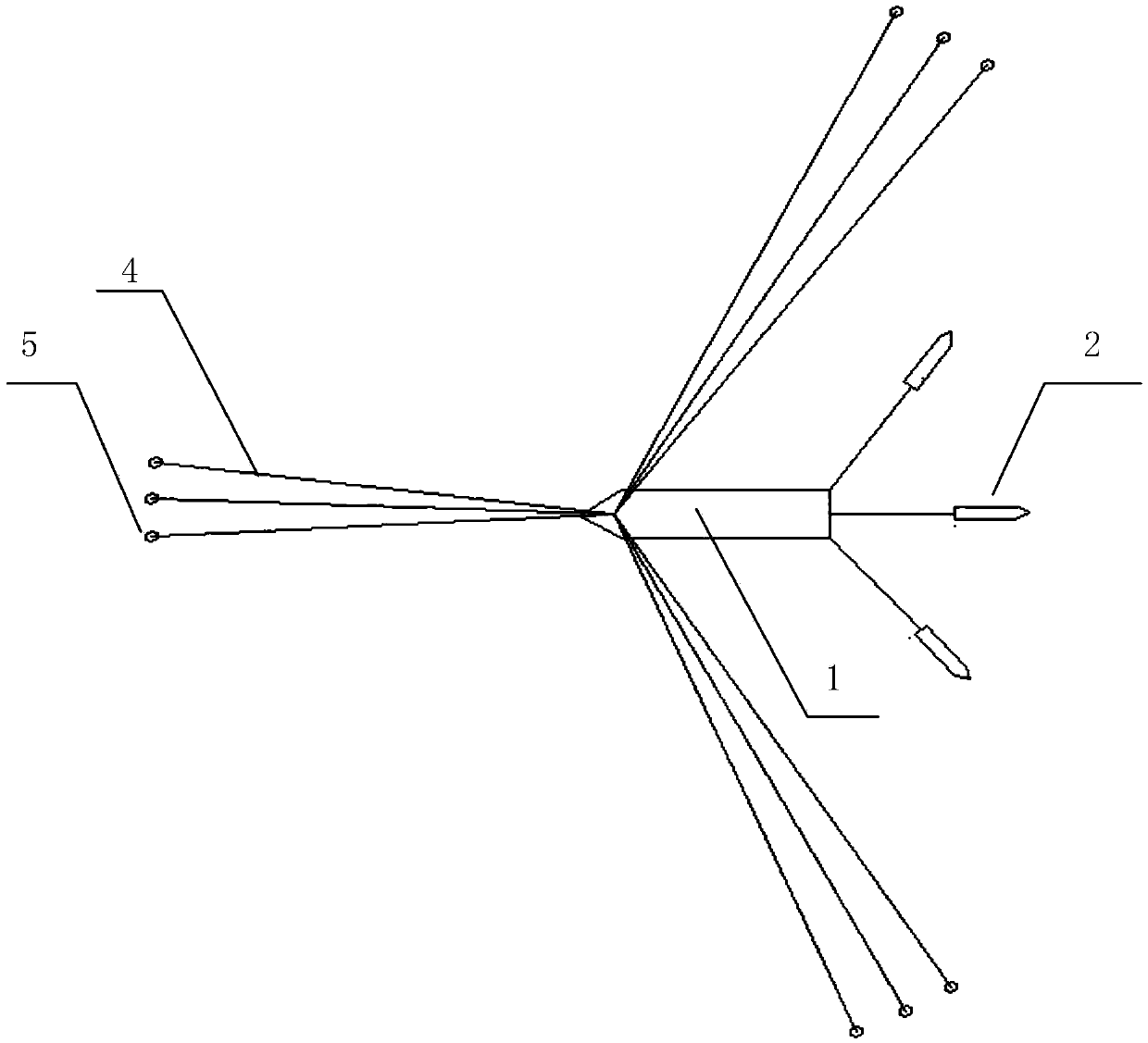

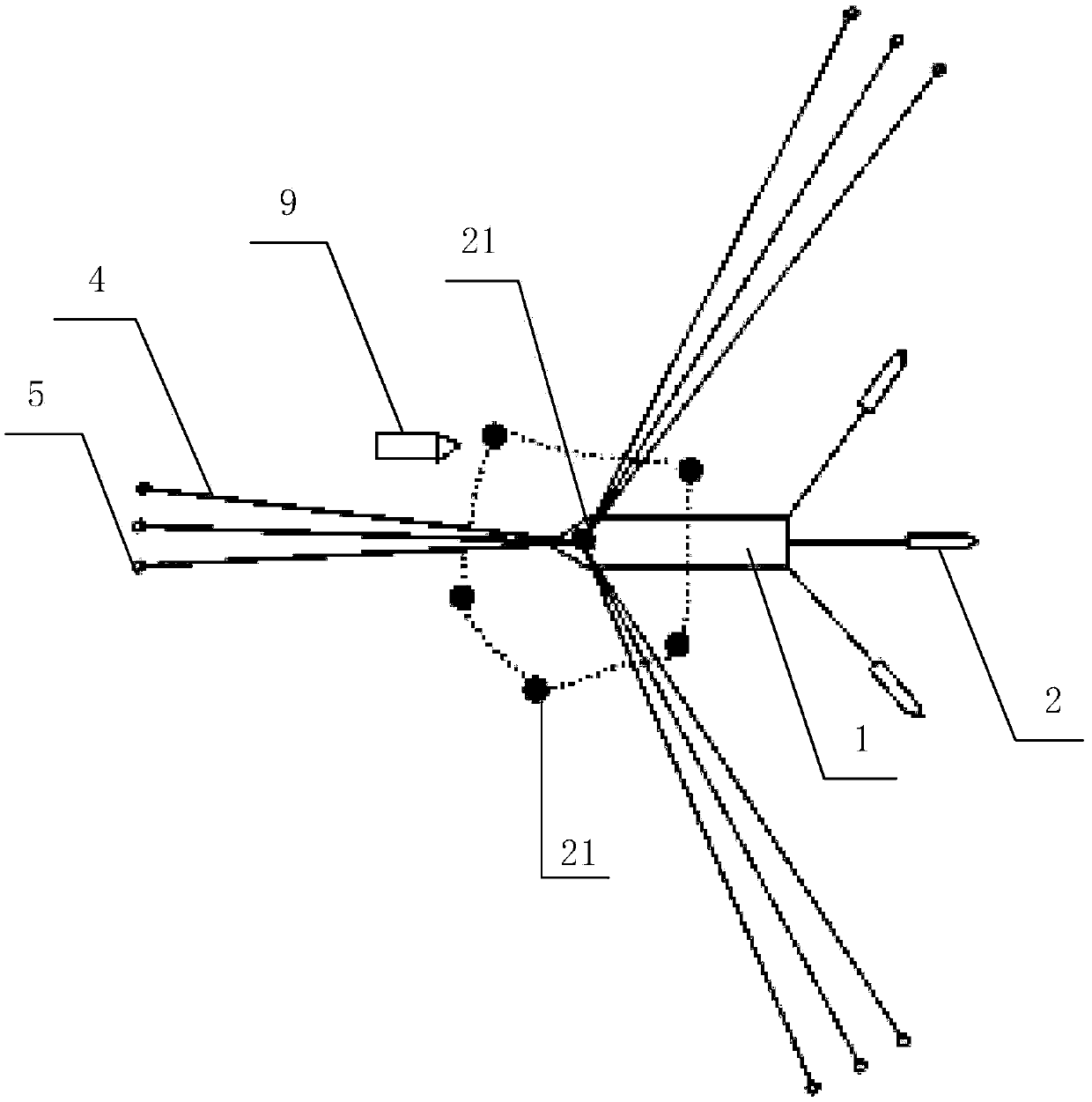

[0064] Such as Figure 1 to Figure 12 As shown, in the first embodiment of the present invention, the method for replacing the mooring anchor leg includes the following steps:

[0065] Step S10, arranging several limit tugs 2 at the stern of the floating production, storage and offloading tanker 1 so that the heading of the floating production, storage and offloading tanker 1 is near a constant angle;

[0066] The limit tug 2 is used to control the rotation of FPSO1 under the action of wind, waves and currents, so as to adjust the heading of FPSO1 so that its heading is near a constant angle, creating conditions for single point 20 in-service construction; , Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com