Label flattening mechanism

A label and platen technology, applied in labeling, labeling machines, packaging, etc., can solve the problems of low accuracy, large error rate, and low work efficiency, and achieve improved accuracy, high operating accuracy, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

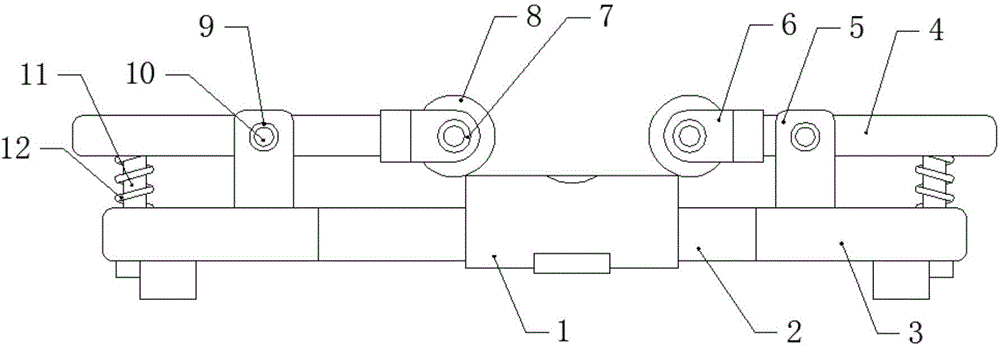

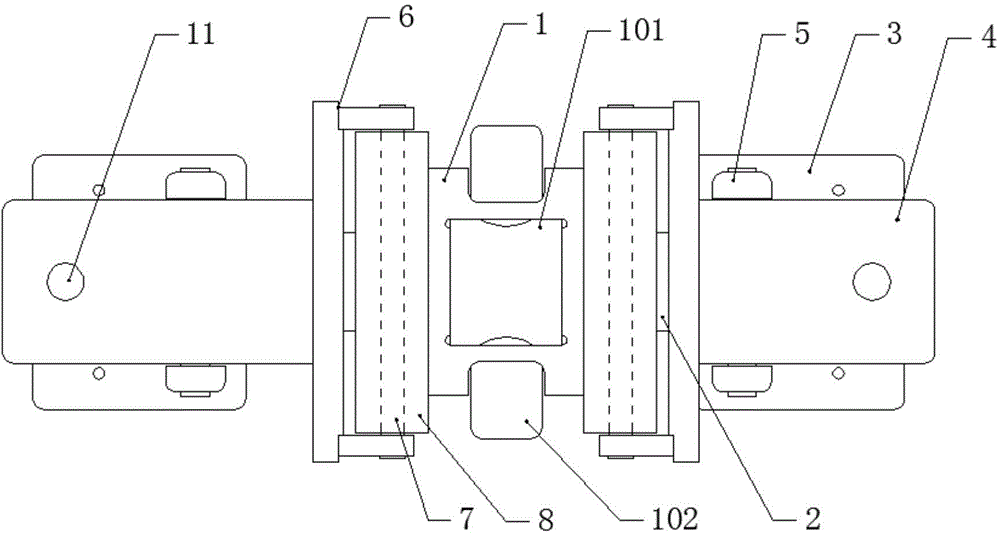

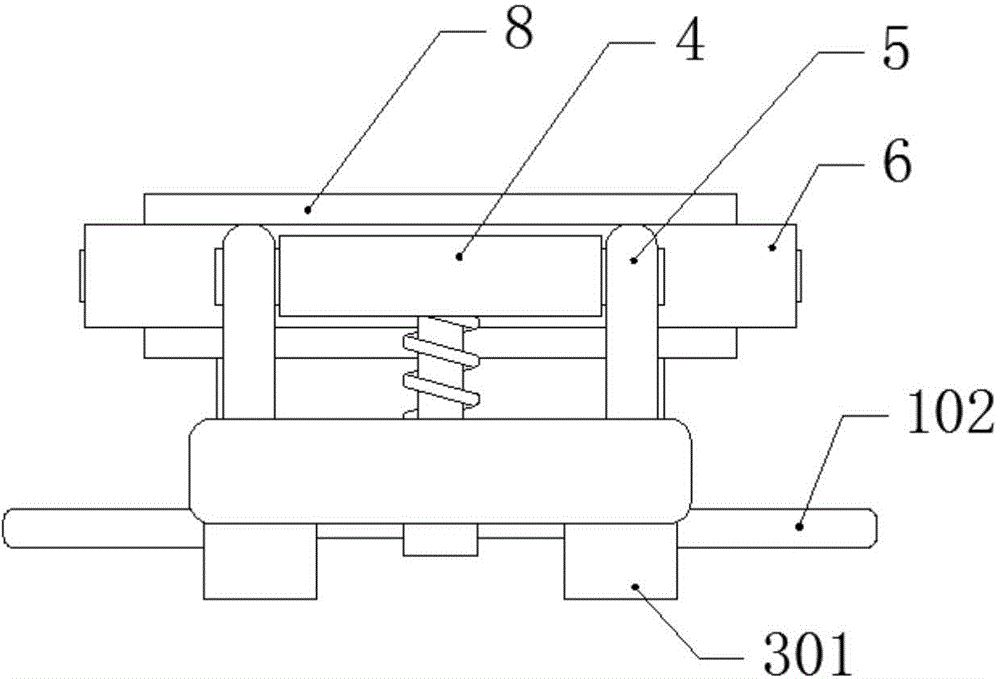

[0018] like Figure 1-Figure 3 As shown, a label flattening mechanism includes a fixed plate 1, a sliding plate 2 and a flattening device.

[0019] On the fixed plate 1, about the central region has a fixed groove 101 for fixing the product, and the periphery of the fixed groove 101 is provided with an arc live opening for conveniently taking out the product. The fixed plate 1 is provided with a slideway matched with the slide plate 2 , and the slideway is located below the fixing groove 101 . The fixed plate 1 is set on the slide plate 2 and can move along the slide plate 2 . The two ends of the slide plate 2 are respectively fixedly connected with the flattening devices at the two ends of the fixed plate 1 .

[0020] The flattening device includes a base 3 , a pressing plate 4 and a pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com