Novel pile foundation detection method

A detection method and pile foundation technology, which is applied in the field of construction and foundation foundation, can solve the problems of pile head damage, inability to use pullout detection, and difficult processing of hoops and pressure equipment, so as to ensure the integrity of the pile body and improve the accuracy , the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

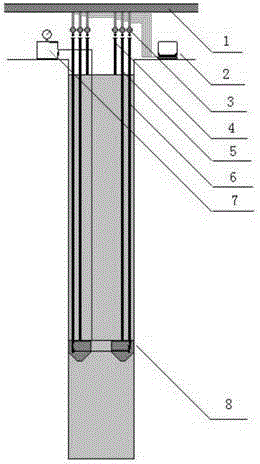

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] A) Loading preparation: 50% of the pre-estimated limit value is taken as the test loading limit value, which is divided into 10 levels of loading, and each level is one-tenth of the loading limit value.

[0026] B) Loading detection: carry out loading in stages, and load in equal amounts step by step, in which the first stage is twice as high as the staged load. When the settlement rate of the pile top reaches the relatively stable standard, the next level of load is applied. The relatively stable standard is: the displacement of the pile top within one hour does not exceed 0.1mm, and it occurs twice in a row (starting from the 30th minute after the application of each level of load, calculated from the settlement observation value of three or more times every 30 minutes). When under a certain level of load, the settlement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com