Water injection backflow prevention end cover of water storage valve

A technology of preventing backflow and end cap, applied in valve details, valve device, valve shell structure, etc., can solve the problems of hidden danger, malfunction, economic loss and other problems of deluge alarm valve, and achieve the effect of avoiding a large amount of gushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

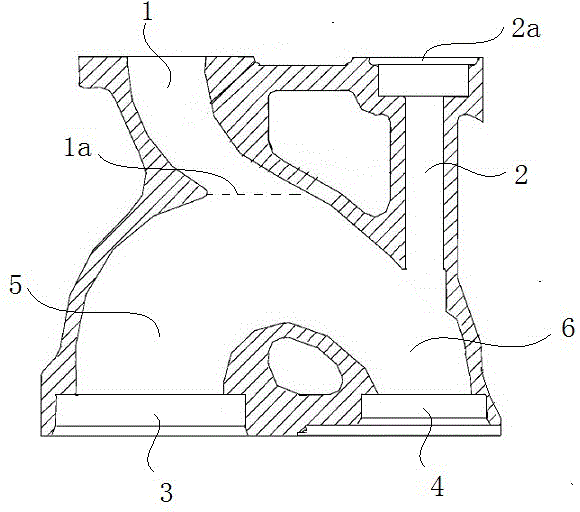

[0012] Such as figure 1 As shown, the water injection anti-backflow end cover of the water storage valve includes: a water injection pipeline 1, a water inlet pipeline 5 is arranged at the lower end of the water injection pipeline 1, and a water inlet valve 3 is arranged at the end of the water inlet pipeline 5. The water inlet pipe 5 is a bend, and under the bend mouth 1a of the water inlet pipe 5, in addition to the water inlet pipe 5, there is also a divergent water pipe 6, and the end of the divergent water pipe 6 is provided with a divergent water pipe valve. 4.

[0013] A longitudinal overflow channel 2 is arranged above the branch water pipe valve 4 .

[0014] The top end 2a of the longitudinal overflow channel 2 is a shower head.

[0015] The curved surface of the water inlet pipe 5 tends to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com